Revolutionized Bifold Doors

Revolutionized Bifold Doors

Straps Are Better

Than Outdated Cables

Some manufacturers still continue to try and sell outdated cable lift

bifold doors - cable doors that not only require frequent maintenance

due to fraying, overwrapping or strands breaking, but also open

much slower, are hard to adjust, are not as reliable as straps, and

are noisier than liftstrap doors.

Straps are rated

for 29,000 lbs.

STRAPS

IN USE FOR 20 YEARS

TRIED, TESTED, PROVEN

Straps Are A Better Design

The strap wraps around the lift drum as the door opens, increasing the size of the drum. The larger the drum's circumference, the faster the door opens. It's ideal the door opens slowly at first and quickly picks up speed, a nice safety feature. It's a clean, strong design. It's quiet, it's simple, and the door opens faster. Straps give your door a Soft Start and a Soft Stop.

“An innovative approach to control the opening and closing speeds of a door, particularly beneficial in ensuring safety and efficiency.”

Wrap-Around Lift Drum

By employing a strap that wraps around the lift drum, this system ingeniously alters the effective circumference of the drum based on the door's position. As the door opens, the strap winds around the lift drum, enlargening its diameter. With a larger circumference, the drum facilitates a swifter door motion. A gradual start followed by acceleration ensures safety, a thoughtful design touch. The mechanism is sleek and robust, operating silently and efficiently to grant swift access. Straps provide a gentle initiation and conclusion to the door's movement.

Soft Start

As the door begins to open, the strap is designed to initially wrap tightly around the lift drum, effectively minimizing its circumference. This smaller initial circumference means that when the door starts moving, it does so slowly. This slow start prevents the door from abruptly jerking into motion, which could be unsafe and startling. It's particularly advantageous in avoiding any sudden strain on the door's mechanism and reducing wear.

Accelerated Mid-Operation

As the door continues to open, the strap progressively wraps around the drum, gradually increasing its effective circumference. This ingenius design naturally leads to the door speeding up in a controlled manner. The gradual increase in speed allows for quicker operation without sacrificing safety, ensuring that the door can open swiftly without any abrupt changes in speed that could be hazardous.

Soft Stop

Towards the end of the door's opening cycle (or at the beginning of its closing), the system is designed so the circumference begins to decrease again, slowing down the door's motion until it comes to a gentle stop. This soft stop mimics the soft start but in reverse, providing a safe, gentle end to the motion that reduces stress on the mechanism and enhances user safety.

Extended Lifespan

Reducing the strain on mechanical parts by avoiding harsh starts and stops extends the lifespan of the door mechanism. The soft start and stop make for a smoother user experience, eliminating the discomfort of abrupt motion. Gradual acceleration and deceleration typically generate less noise than sudden starts and stops, making for a quieter operation.

By allowing the door to open faster between the initial and final phases of its movement, the system ensures quick access while still prioritizing safety. This design's blend of safety, efficiency, and user comfort, thanks to its innovative use of a variable circumference lift drum mechanism, represents a significant advancement in door mechanism technology. It demonstrates how thoughtful engineering can enhance everyday experiences through simple, yet effective design changes.

The Simplicity of the New

Latch Strap Is Truly Amazing!

Straps do the lifting and now straps do the latching! Schweiss did away with all the cables, chains, sprockets and pulleys; and it now has 90 percent less moving parts. This is a real game changer in the bifold door world! It doesn't get any better than an all-strap door.

Added Protection - Unlike Other

Bifold Door Latch Mechanisms

Unlike other bifold door latch mechanisms, the new Schweiss design will firmly hold the door against your building in all positions; securing the door when open/partially open and will firmly lock the door when closed. It offers added protection from wind gusts while the door is in any position during operation. This innovative strap latch pulls your doorframe securely against your building making for a tight seal with each use.

No Extra Motor Needed

Utilizing the door's existing drive line, it eliminates the need for an extra motor and additional parts such as additional cables or rod linkage.

A Better Design

This strap latch innovation simplifies the latching mechanism, reducing potential failure points, maintenance requirements, and operational complexity.

Sleek Appearance

The “Strap Latch” boasts an exceptionally sleek appearance, seamlessly integrating with the same style strap that lifts your door, now doubling as a secure latch.

Everybody Wants...Strap Latches And Remote Controls

Straps Stay Connected...

Straps secure the door while open!

Straps secure the door while closed!

Straps secure the door while operating!

Straps secure the door from wind gusts!

Straps seal the door better!

Straps Keep Doorframe Connected To Building At All Points of Travel!

Clean Look... Cleaner Design!

Straps Do All

The Latching...

An all strap bifold door with

no more need for cables, extra motors or additional parts!

Straps Keep Doorframe Connected To Building At All Points of Travel!

Straps Do All

The Latching...

An all strap bifold door with

no more need for cables, extra motors or additional parts!

CABLES vs. LIFT STRAPS

Market Shaking Inventions . . . Schweiss Lift Straps

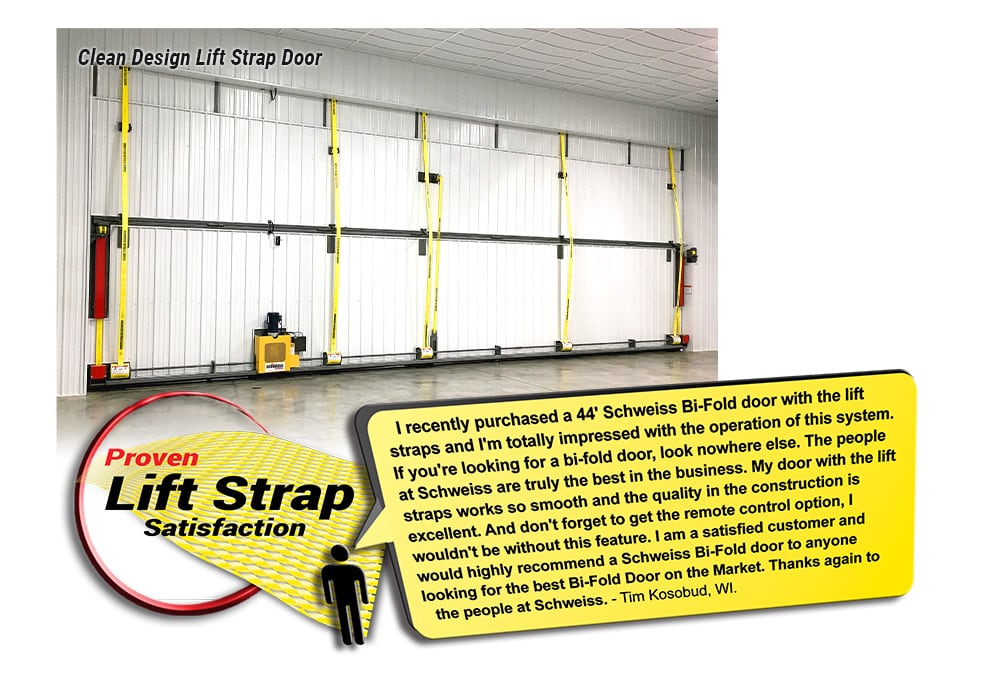

The most obvious "market shaking" improvements for the Bifold Door is the addition of the patented lift-straps along with the new strap autolatch systems, two great features. Schweiss Lift Straps have revolutionized the door world by opening and closing much more quickly, quietly and effortlessly. Not only are they safer, but they're also easy to install and much longer lasting. Strap doors are leading the bifold door market!

Schweiss Doors have been doing doors for over 46 years, manufacturing two great styles of doors, Hydraulic Doors and “Lift-Strap” Bifold Doors. Schweiss Doors evolved with the times and greatly improved, creating a product that everyone is asking for!

Straps Are Easy To Handle

Straps are easy to handle, easy to install, easy and safe to tie off at the very top of the door, unlike cables that require thimbles and cable ends and special hardware. Straps are easier to install. Straps wrap on top of themselves / no chance of criss-crossing like cables do when they have slack in the cable. Straps have taken over the bifold door market.

Straps over cables in the bifold door market represents an evolution in the approach to both the functionality and safety of bifold doors. This shift towards straps is attributed to several advantages over traditional cable systems:

Straps are lighter and more flexible than cables, making them easier to handle and install. This simplicity speeds up the installation process and reduces labor costs.

Because straps can be easily tied off without needing these extra components, The chance of installation errors and potential failures is reduced. Straps present a safer and more reliable method than cables without the need for any special hardware.

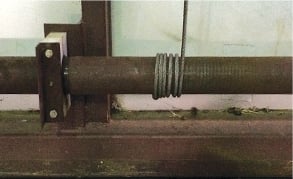

Cables Criss-Cross When There Is Slack

Cable's tendency to criss-cross when there is slack not only affects the functionality and aesthetic of the door but can also pose safety risks if the cables tangle or wear unevenly. Straps, on the other hand, mitigating the risk of crossing and tangling because they wrap on top of themselves.

Straps . . . The Preferred Way

The inherent benefits of straps, such as ease of use, installation, safety, and maintenance, have led to their preferred use in the bifold door market. Manufacturers and installers tend to favor them for these reasons, and their popularity is indicative of their effectiveness and efficiency.

The transition to straps in the bifold door industry exemplifies how innovations in materials and techniques can lead to improvements in bifold design, safety, and user satisfaction. As the door industry continues to evolve, we may see further adoption of straps in other areas where cables have traditionally been used, driven by the demand for safer, more efficient, and easier-to-use alternatives.

PROVEN DESIGN

Schweiss Lifts straps have proven to be by a far superior method of lifting any bifold door. Lift straps wrap on top of themselves by design, eliminating any common cable issues, like overlapping, rubbing and fraying. Lift straps are much quieter than cable doors!

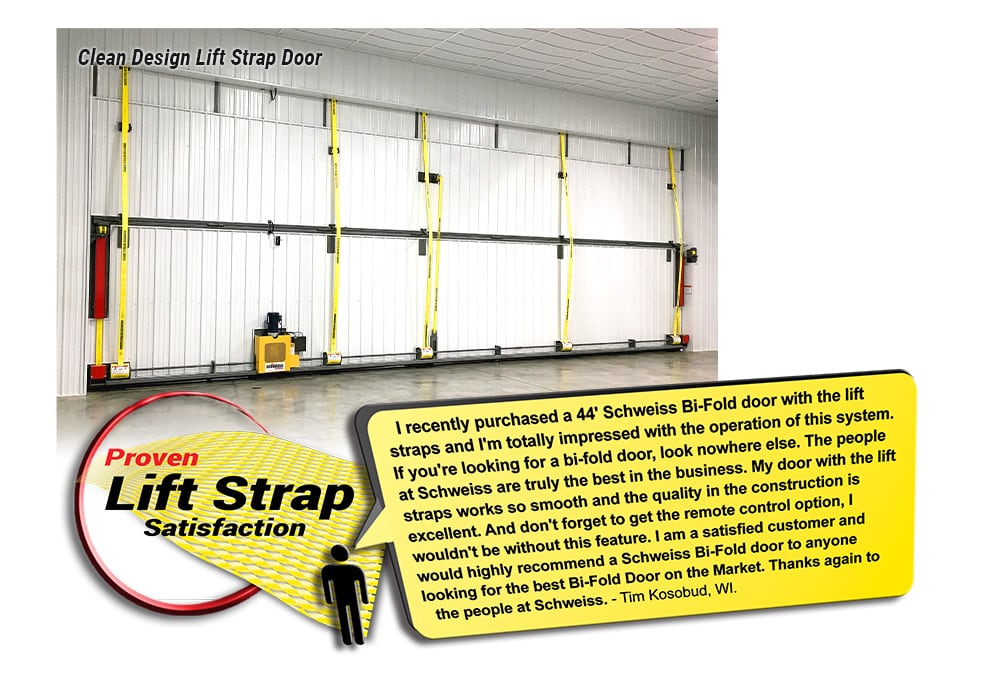

CUSTOMER TESTIMONIALS ABOUT LIFT STRAPS

"We were having trouble with frayed cables. I'd recommend liftstraps to anyone."

"Schweiss can convert any

outdated cable lift bifold door to a 'Lift Strap' bifold door"

"I do like the liftstraps.

they're a lot less maintenance faster and quieter."

Bifold Doors Keep Getting Better and Better!

Other Cable Door Manufacturers Are Fighting Back

Offsetting The Cables As They Wrap Up On The Lift Drum

Offsetting the cables during lifting of a bifold is a great concept, until your cables don't have the proper tension. Then you end up with messed up cables, unlike straps that wrap on top of each other. Tension is not an issue with lift straps nor do they get messed up. Straps are a perfect design... trouble free.

Adding Numerous Lift Points

The only reason a cable door manufacturer would add more cable lifts to a door is because cables are not as strong as lift straps. More cable lifts means more maintenance and more expense - why fight the outdated cable concept and costs involved! Using more cables

may translate to less load per cable. But who wants more cables on a door if cables

are already known to cause issues when not maintained properly?

Offering a 10 Year Warranty On Cables

A cable is a cable no matter what sales pitch they throw at you. It's not about the cost of the cables... Maintaining proper tension or replacing cables is the issue. It takes time and labor to maintain or replace the cables and it's no easy task!

Cables are harder to work with!

CABLES END UP COSTING MORE IN MAINTENANCE

What bifold door customers are saying about cables:

Keeping proper tensioning of the cables is critical on any bifold door but the cable clamps make that very difficult. Cable doors are also slower, wear out sooner and are harder to replace. They require more maintenace and are not as reliable or quiet as lift straps. Schweiss Lifts straps are proven to be a far superior method of lifting any bifold door. Lift straps wrap on top of themselves by design, eliminating any overlapping issues and wear!

Lift Straps are the cure for your cable problems

Yes, Schweiss Will Convert Any Brand Bifold Door To “Lift Straps”

Schweiss has received thousands of calls from cable bifold door owners wanting to retrofit their outdated cable door system to the "Schweiss Liftstraps".

“Strap Conversion Kits” Are Available!

P.S. I can see why those other cable door

manufactures are fighting back but the truth is no one

has ever converted a strap door back to cables, because . . .

CABLES USED TO BE YOUR ONLY OPTION . . . NOW

CABLE DOORS ARE OUTDATED

HERE ARE SOME REASONS WHY...

Straps Are A Superior Solution To Traditional Cables

Straps attach directly to the lift drum and securing with a ratchet near the door’s top, straps offer a more straight forward setup than cables, which require clamps, stops, and thimbles. Straps lead to easier and faster installation and less potential for parts to fail. The ability of straps to have slack without affecting the door’s operation is also a significant advantage.

Our customers praise the innovative use of lift straps as opposed to traditional cables in door opening mechanisms, when used in bifold door applications. Schweiss, a known manufacturer in the industry, introduced these new lift straps as a superior solution to traditional cables.

Innovative Solution

Lift Straps are an innovative alternative to traditional bifold cables in door opening mechanisms with a cleaner appearance compared to cables, due to their resistance to fraying and rust. Straps are highlighted as easy to handle, which means easier installation, adjustment, and maintenance.

Durability and Safety

Straps are not only stronger but also safer and more durable than cables due to materials used as well as less wear and tear over time. Unlike cables, which can criss-cross and potentially jam or damage the mechanism, straps are said to eliminate this risk, making for a more reliable system. The ability of straps to have slack without affecting the door's operation is also a significant advantage. By attaching directly to the lift drum and securing with a ratchet near the door's top, straps seem to offer a more straightforward setup than cables, which require clamps, stops, and thimbles. This simplification could lead to easier and faster installations and less potential for parts to fail.

Customers Trust The ‘New Lift Straps’

This innovation is not only theoretically beneficial but has also earned the trust of actual users, offering a proven track record of performance and satisfaction. This endorsement for lift straps over cables signifies a potential shift in preference towards newer, more efficient technologies in the field of door mechanisms. Straps offer tangible benefits in operational reliability, safety, and user convenience, reflecting advancements in materials and mechanical design.

Straps

- Straps are stronger.

- Straps are more durable than cables.

- Straps won't criss cross like cables.

- Straps are faster.

- Straps are quieter.

- Straps are safer.

- Straps are easy to handle.

- Straps are rated to 29,000lbs.

- Straps can have slack and still work.

- Straps are easily shielded - clean look.

Straps Are Proven

Cables

- Cables wear out!

- Cables fray!

- Cables overwrap!

- Cables are slower!

- Cables are noisier!

- Cables require more maintenance!

- Cables are hard to adjust!

- Cables are rated for only 7,200 lbs!

Cables Are Outdated

SOME MANUFACTURERS ARE STILL TRYING TO SELL OUTDATED CABLE DOORS

Slack cables cause problems

Cables require more maintenance

meaning more down time

Cables wear out faster and fray

easily over time

Uneven cable wrapping causes problems

Cables wrap next to each other

and cause wear

Cables tend to walk all over the lift drum and cause problems

Cables rated for only 7,200 lbs

Question Of The Day:

Why Would Anyone Want a Cable Door?

Schweiss Doors of Fairfax, Minnesota, USA have been on the market for over 46 years. We manufacture two great styles of doors, the New Red Power Hydraulic doors and the famous "Lift-Strap" Bifold doors - successfully for more than 28 years. What some people don't know is that they've evolved with the times and many improvements have gone into them, creating a product that everyone is wanting!

Market Shaking Invention

The most obvious 'market shaking' improvements for the Bifold Door is the addition of the patented lift-straps and the strap autolatch systems - two features not offered by any other door manufacturer. Schweiss Lift Straps have revolutionized the door world by opening and closing much more quickly, quietly and effortlessly. Not only are they safe, but they're also easy to install, and they're much longer lasting. It's a win-win for the customer and straps doors are leading in the door world. Word is spreading fast.

"Lift Straps," Tested and Proven

For years, bifold doors have been lifted and lowered by the conventional means of steel cables. Schweiss Bifold Doors have been using the popular, long-lasting lift straps for over 28 years - now 99 percent of our customers are demanding polyester lift straps for this function. Why? Because lift straps offer more lifting ability, won't fray or overwrap! The strength-to-weight ratio on straps is extremely high. The 3-inch straps are rated at 29,000 lbs, where 1/4" cables are rated at only 7,200 lbs. In addition, the safety factor on straps has well over a 5:1 ratio.

BIFOLD DOORS HAVE BEEN AROUND FOR YEARS . . .

SCHWEISS KEEPS MAKING BIFOLDS BETTER!

Everyone's Fed Up With Cable Doors

Cables are the old way. Everyone knows cables can over time have a tendency to fray. Frayed cables can break and doors can come crashing down on aircraft, machinery or even people. Cables require more servicing, are hard to work with and difficult to replace. Replacing cables with cables is a timely and costly expense, and can be a real safety issue if the cables are not kept in good condition.

Once You Try "Lift Straps" You'll Never Go Back to Cables

Schweiss's excellent success with the New Lift Straps has revolutionized the door industry. It's a no-brainer, why bother with cables, it becomes obvious. You'll understand why the New patented Lift Straps are the smarter way to raise and lower your bifold door, smoother, safer, faster, quieter. Like a customer once said:

“You never would even think about buying a vehicle without airconditioning. Why would you ever buy a door without Lift Straps?”

Huge Advantage - 10 Year Warranty

The strap advantage is huge, straps are longer lasting, never rust, never tangle, are flexible, open a door faster and are 100 percent quieter than steel-on-steel cables. With lift straps, door owners get a "soft start" and "soft stop," adding to the life of the bifold door. Schweiss stands behind the "New Lift Straps" by carrying a 10-year warranty and straps outlast cables well over three times.

"How Can You Say that "Lift Straps are the Best?"

Schweiss has been receiving calls from door customers all over the country asking if they can modify or retrofit the "Schweiss Lift Straps" on their doors that currently are operating with a cable system.

They Start Out By Asking:

“I know it's not your bifold door, but can we buy just the 'Lift Straps' and change my door over?”

“We have seen our neighbor's doors with your lift straps, would it be possible to convert/switch over my door to the Schweiss Lift Straps?”

“I just purchased a new Schweiss Door six months ago with lift straps and we have two of your Schweiss doors with cables. Do you have a kit to put 'Lift Straps' on my older cable doors? We are really happy with the New Strap design!”

“I have an older model Schweiss Bifold Door, can we change over to the 'Lift Straps', what's the cost, and is it possible?”

Schweiss has designed and figured out a way to modify any bifold that's ever been manufactured. Retrofitting an existing cable door over to the Patented Schweiss design "Lift Straps" has brought relief to the customer with the old vintage cable bifold doors. Finally the customers with cables can be at ease, they're able to do away with the antiquated cable lift design and retrofit any style door over to the latest and greatest Schweiss Patented "Lift Straps."

Comments from customers who did the conversion:

"The Strap conversion made my door better than new!"

"What a nice Improvement to an older door!"

"The straps and auto latches -- what a great improvement!"

"You guys are good, thanks for the neat invention!"

"Should have done the strap conversion years ago!"

"If anyone asks, send'em my way and I'll be your salesman. I love my door now!"

SCHWEISS RESPONDS:

"We are more than willing to take a look at your current door and help modernize it with the "New Lift Straps"

Lift Straps Take the Place of Cables

Introducing a new way to lift our bifold doors. Now available is our new, patented, "lift straps" that take the place of aircraft cables to raise and lower your door. The lift straps make our door Faster, Safer, Simpler, Easier, and Quieter than any other bifold door available to you on the market today. Schweiss Bifold Doors is constantly on the move, trying new and better ways. Our business Goal: Give the best money can buy at very affordable prices.

Schweiss designed and patented a custom made polyester Lift Strap that provides a new alternative to steel cables unlike any on the market to open bifold doors. The Schweiss Lift Strap is durable and lasts longer than steel cables. It requires less maintenance and it is very easy to replace. 99 percent of our customers are demanding the popular "New Lift Straps" on their Schweiss Bifold doors.

How Does the new "Lift Strap" work?

The strap wraps around the lift drum as the door

opens, increasing the size of the drum. The larger the

drum's circumference the faster the door opens. It's ideal:

the door opens slowly at first and quickly picks up speed, a nice

safety feature. It's a clean, strong design. It's quiet, it's simple, and the door opens faster.

With the new "Lift Strap," Schweiss also offers a new strap tightener system which takes up

slack in the belting. This is a real nice feature for keeping the proper tension on the "Lift Straps"

The Real Advantages!!!

Facts of Straps

- Faster

- Safer

- Simpler

- Easier

- Quieter

- Smoother

- Proven

Strap Vs. Cables “The Real Advantages”

Long Lasting •

All straps are polyester, they never rust, making it more durable and longer-lasting than steel cables.

Flexible •

Straps are flexible, which means longer life span than cable.

Quieter •

Straps are 100% quieter and smoother running on the door.

Speed •

Straps will increase the opening/closing speed of the door due to the size of the drum circumference. The door is opened

slowly at first then speeds up, a good safety feature. You get a Soft Start and a Soft Stop. It doesn't get any better.

Alignment •

Straps never get tangled or criss-crossed.

Load •

Straps evenly distribute the load on the door.

Life •

Straps have three times the life of cables.

Tension •

When it comes time to tighten the straps, it's easier to use a ratchet tightener.

Cost •

Cost of straps are competitive to the cost of cables.

Warranty •

NOW offer a 10-Year Warranty on original lift straps.

Converting •

Schweiss has "Cable-Lift"-to-"Lift-Strap" conversion kits that adapt to most presents doors with factory.

Safety Strength •

Safety factor on the straps is well over 5:1.

Strength-to-weight ratio on our straps is extremely high.

3" straps are rated at 29,000 lbs / 1/4" cables are rated at 7,200 lbs.

That is why the Schweiss Lift-Strap System has a NEW 10-YEAR WARRANTY!!

Something Worth Reading About Lift Straps

COMMON QUESTIONS ASKED

A Note From Schweiss

When our patented lift-strap system became such a popular choice with door customers, it was

only logical that the competition would come out swinging, especially if a cable system is the only

system they offer. New Technology is wonderful, even in the door business.

What Is The Competition Saying?

• Cable systems are more durable, more reliable, and safer than straps.

What Do We Say?

• NOT SO! In fact, our "Lift-Strap" system beats the competition on all three of those

factors. However, Schweiss continues to offer cable doors should the customer want a

cable system. We believe in offering the option. You see that in many other features

available to our customers.

The Bottom Line:

• Why bother with cables? Lift Straps are faster, safer, simpler, and quieter. End of debate.

• Our Lift-Strap system outlifts, outlasts outsells any cable system.

• Today, 99% of Schweiss Bi-Folds are ordered with Lift Straps.

• Since we introduced our Lift-Strap package, cable systems have become hard to sell.

Why are Schweiss Lift Straps the

Best Way to Lift Bifold Doors?

• Faster - Gear Ratio changes as the door opens.

• Safer - 29,000 lb. Tensile strength, compared to 7,200 lbs. Cable.

• Easier - Install a strap, or install a cable. What a difference.

• Simpler - Never will lift straps tangle. How can they lift?

They wrap onto themselves.

Specific Facts on Straps:

• Straps outlast cable.

• Straps are very low maintenance.

• Straps are clean, neat looking. No abrasive strands.

• Straps will stretch with use, so we designed a simple

strap tightener. Give it one or two clicks and your strap

is tight again. How simple does it get?

How Do You Know The Straps Are So Reliable?

All our straps are made of polyester material that has an indefinite working life. We did vigorous in-house

testing of the New Lift Strap system, the equivalent of 20 plus years of conventional usage, without a single malfunction.

The polyester material we are using has remarkable strength. That is why we confidently provide a 10-year warranty on our

Lift Strap system. Like the 'Energizer Battery' our customers are finding Lift Strap systems keep working and working and

working.

Can I Still Get Cables?

The cable lift system is still the standard but that is rapidly changing. Already 99% of our doors get ordered with the new Lift

Strap System so it is obvious customers are catching on fast and for all the right reasons...faster, safer, simpler, easier, and

quieter.

Can I Put Straps On My Existing Schweiss Bifold Door?

Yes, our older Bifold doors can be retrofitted with the Lift-Strap System. Yes, the Lift Strap System can work on Schweiss doors,

depending upon the construction and mechanics of each particular door. However, I would not advise that it would work properly on

EVERY bifold door, regardless of manufacturer. And there is no logical, or legal thought that we would endorse the use of our

patented lift-Strap System on another manufacturer's door.

We Took The Work Out & Put Safety In By Keeping The Proper Tension

On Our Lift Straps - It's Win-Win For The Customer.

We have yet to sell a REPLACEMENT LIFT STRAP! They simply last, and last and last. And that is time, labor and $$$'s saved for the

door owner. The 29,000-Lb. Tensile strength is a tremendous safety factor. That is why the Schweiss Lift-Strap System has a 10-YEAR

WARRANTY!

Soft Start / Soft Stop

The 'mechanics' of our lift-strap system are uniquely simple: As the strap wraps on the lift drum the door quietly opens quicker until it

reaches the automatic stop position. Should you stop the door at any position, the door GENTLY comes to a stop.

You get a soft Start and a Soft Stop. It doesn't get any better.

Tensile Strength Comparison

STRAPS ARE...

- Quieter

- Safer

- Easy to install

- Last longer

- Faster

- Easy to maintain

SCHWEISSS GOES TO 10-YEAR WARRANTY ON LIFT STRAPS

Unheard of in the commercial door world is a 10-year warranty. But not for Schweiss Bifolds! Customer satisfaction has been so

universally supportive that Schweiss Doors, world leader in the manufacture and marketing of the famous Schweiss Doors, is now

providing a 10-year warranty on our popular Lift-Strap mechanism.

Since our patented Lift Strap was introduced over 28 years ago, we have yet to replace a system due to mechanical failure. Remarkable, considering that Schweiss Doors have now been marketed across America and into other countries. With its 29,000-lb. tensile strength, this nylon strap is virtually fail safe.

Initially marketed with a 3-year warranty, Mike Schweiss said, "Engineering competence and rugged durability are trademarks

of our products. Extending to a 10-year warranty on our Lift Strap units is simply showing our customers that they can expect

total performance on a Schweiss door system."

Schweiss continues to be the door leading manufacturer always on the cutting edge,

offering both Hydraulic and Bifold choices.

Comments From Customers

Below are testimonials and comments from customers who had outdated, older style cable lift doors that have been converted to the “New Liftstraps”. . . And happy customers who have purchased the number one selling lift strap doors.

Now you have read the strong testimonials above, you'll ask yourself . . .

"Why would anyone ever consider purchasing an cable door!

Customers Calling The Shots

When we introduced our patented nylon Lift Strap system over 28 years ago, we didn't expect customer response to be so overwhelming. In no uncertain terms, virtually 99% of our new customers INSIST on the Lift Strap package. Here's what you are telling us: "They are so much smoother." "It looks and sounds professional like the best technology, system." And the comment we treasure the most: "Thank you for simply providing the very best door opening/closing system in the Bifold Door Industry!" You bet we like our customers call the shots. Best of all we've NEVER had a malfunction, never had to do a replacement on a Lift Strap door. That is unheard of with cables. And that is why we now offer Lift Straps with every Schweiss Bifold order. Our customers are telling us what they want. We're delivering it! - The New Lift Straps - A Home Run for the end user!

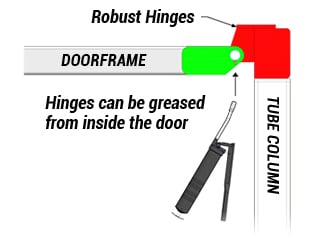

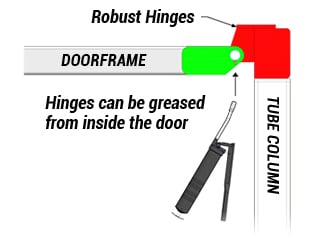

Customers Welcome Greasable Hinges

HIGH-QUALITY HINGES FOR HEAVY-DUTY DOORS:

Importance of choosing the right hinges for heavy-duty doors, such as those used in industrial, commercial, or specialized applications like aircraft hangars, agricultural buildings. Schweiss Doors, has built a reputation over the years for manufacturing doors that are robust, durable, and accompanied by hardware components, like their extra heavy-duty steel hinges, which are designed to withstand the demands of large and heavy doors. Hinges designed for heavy-duty applications are made from materials that can withstand the elements, resist wear and tear, and require minimal maintenance. This is crucial for installations in harsh environments or where the doors are frequently used. Extra Heavy duty steel hinges utilizing high-grade steel that ensures strength, resistance to wear, and longevity.

Manufacturing doors for 46 years all types and sizes. Schweiss has the strongest trouble free hinges in the industry! Features like easy lubrication ensure that the door remains operational without much downtime for maintenance. This is particularly important in commercial settings where time is money. The ability to easily lubricate the hinges ensures they remain in optimal working condition, reducing friction and wear while allowing for quieter smoother operation.

HINGE SURFACE AREA

Hinge surface area is critical on large moving doors. Over the years, we all have heard of hinge failures on others doors. Large hydraulic cylinders are putting extreme forces on each of the outer hinges of the doorframe. Schweiss has designed and patented a robust hinge with more surface area to evenly distribute the loads of a moving one-piece doorframe. Look at the hinge surface area. The stresses on the very outer hinges are immense. With that being said, take one look at the patented Schweiss hinges and you'll clearly see the workmanship, strength and functionality of each hinge.

GREASABLE HINGES

It's very important to be able to grease the door hinges with a heavy viscosity grease. When grease is used on the hinges of a large moving door it avoids unnecessary wear and adds longer life to the hinge and the doors operation. It's a common manufacturing practice to use grease on the critical wear points and load points to avoid unnecessary wear just like in the industrial equipment world with implements such as payloaders, skidloaders and other industrial equipment that are being operated around the clock.

The new hinge design with grease points on every hinge segment enables owners - whether they be private individuals or commercial customers - to periodically grease their hinges from inside the doorframe without having to go through the cumbersome process of first removing the top rubber weather seal.

Advantages of Grease

Using grease on the hinges is a better method of lubrication.

Using grease on the hinges is the industry standard.

Using grease on the hinges makes for a quiet door.

Using grease on the hinges makes for a smoother operating door.

Using grease on the hinges extends hinge life.

Greasable hinges last forever.

Look at the Schweiss hinge, it has more lubricated surface area to give you longer life.

Others rely on bushing FOR LUBRICATION

Doors move and flex as they open and close. The forces on each hinge vary during operation.

Not all bushings wear evenly.

Bushing wear thin over time.

Worn bushings offer less lubrication.

Less hinge surface area to distribute the door loads across the door header tube.

No way to inspect the bushings when the hinge pins are welded in - not removeable for inspection.

Almost impossible to replace the bushings when the hinges pins are welded in solid.

Greasable hinges LAST FOREVER!

. . . only manufacturer to offer greasable hinges

SCHWEISS DOORS KEEP GETTING BETTER

“The straps run the door up faster and safer and I like the 10-year guarantee.”

Jim Jorgenson

Westbrook, MN

“We also like the convenience of the liftstraps being faster than the old cables on our door.”

Mark Delaney

Elmaro Vineyards,

Trempealeau, WI

“We were having some trouble with frayed cables. I'd recommend liftstraps to anyone.”

Tom Thornton

Churdan, IA

“I was replacing cables that were always fraying and hoping for more door speed, which the straps give me.”

David Albrecht

Fairbanks, IA

“The decision to get liftstraps on my bifold door was more of a safety issue for me.”

Doug Peterson

Fairmont, MN

“We're having zero problems now with the liftstraps.”

Charlie Molden

Sleepy Eye, MN

“I'm very happy with the liftstraps and I wouldn't be without the auto latches.”

Doug Breitkreutz

Hector, MN

“So far so good on the strap conversion, I'm very happy with it.”

Ami Sela

South St. Paul, MN

“The straps are faster and just keep feeding up with no problem. I'd recommend them.”

Brad Hanson

Bushnell, SD

“The straps are 1000 times better than cables. My cables were breaking and keeping them adjusted was a big hassle - it was not a safe deal. I'm very pleased with the liftstraps and would recommend them to anyone.”

Rick Welsh

Welsh Equipment,

Dodge Center, MN

“We converted to liftstraps for reliability and aesthetics.”

Graham Lavender

Perry, GA

“The straps were pretty easy to install. They are quieter, quicker and safer, and the safety shield system is really nice. I'm real happy with it.”

Brad Poltermann

Genoa City, WI

“The straps are rated for so much more strength, and now my door opens faster! We wouldn't order a door without "Lift Straps on them, they are working great.”

Fred Patterson

Novado, CA