Hydraulic Secrets

Schweiss Offers Choices - Manufacturing both hydraulic and bifold doors.

The One-Piece® hydraulic door design is another alternative to the two-piece bifolding door. Schweiss, the #1 leader in the door industry, offers customers choices when it comes to selecting doors for their buildings. Please read the following and let it be a helpful guide to selecting the door that best accommodates your building with the intentino of getting the most for your dollar with the best design money can buy.

Hydraulic

Less moving Parts

Clean Design / Clean Look

Simplicity, quality and strength are standard on every One-Piece® hydraulic door Schweiss manufactures. Today Schweiss is the acknowledged No. 1 builder of One-Piece® hydraulic doors. Listening to our customers, and building quality and convenience into our products is what we do best. We have a talented team with 46 years experience that welcomes new challenges. We have the product to show for it.

One set of Heavy Duty hinges

One-Piece doorframe with double push tubes

Two cylinders with spherical bearings

Electric powered hydraulic pump to raise and lower the door

Requires Less Headroom

Do you need a sturdy, quick opening One-Piece® door? A hydraulic door is ideal in situations where maximum clear opening must be maintained. The hydraulic door swings up and away from the building so there is no loss of headroom outside or inside the building. With the push of a button, your door will quietly, quickly, and safely open, giving you access to the full available space your building has to offer. A builder can easily work this new Schweiss One-Piece® Hydraulic door into a structure where headroom is an issue.

Options

Schweiss hydraulic doors offer options such as:

Special Features

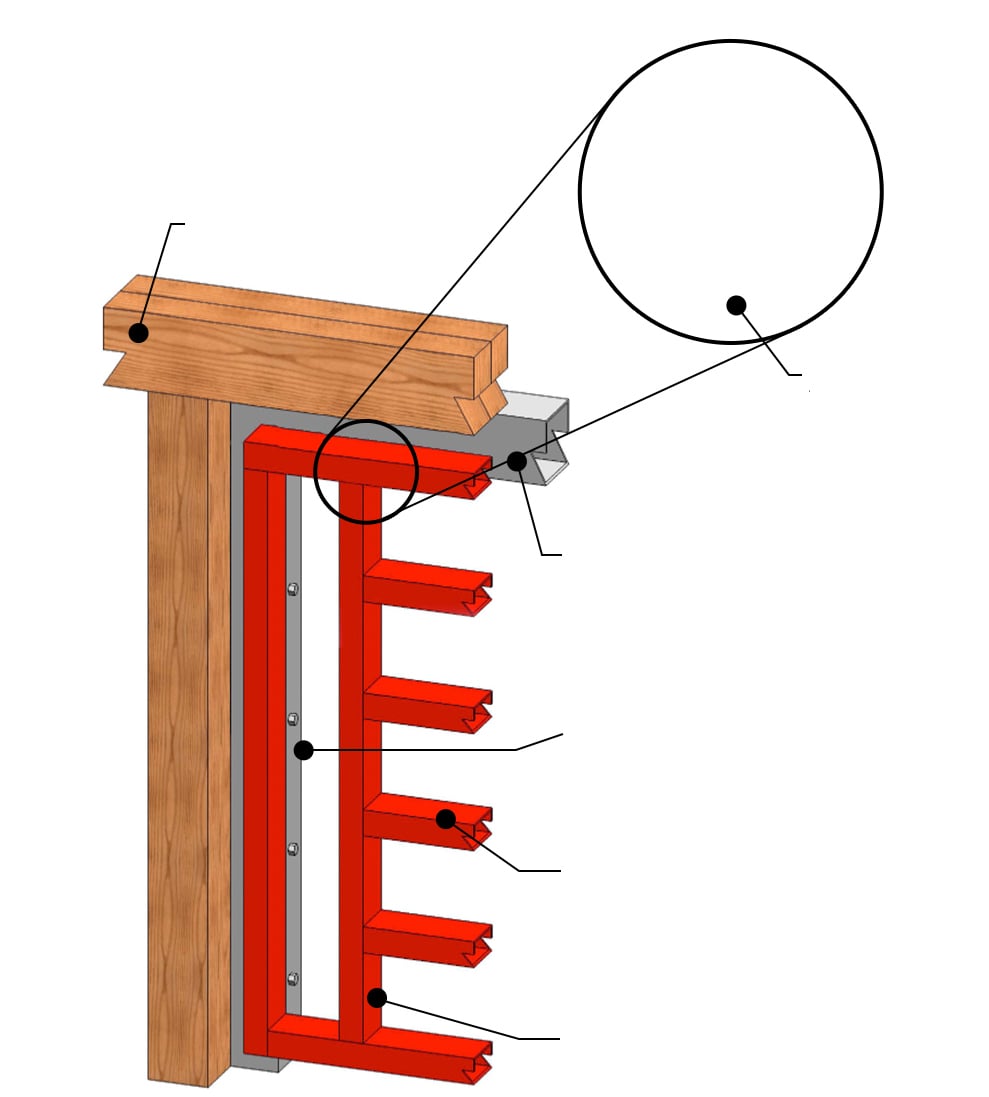

A special feature of the custom-built One-Piece® hydraulic door is that it comes pre-assembled, pre-welded and delivered pre-hung within its frame for easy installation. The buyer/builder gains tremendous flexibility, saving time and money.

Doors come with their own Subframe

Comes pre-assembled, with its own header tube and vertical side columns that provide added support for your building structure.

The doorframe is pre-welded and pre-hung within the subframe for easy installation.

Pre-locates the hydraulic cylinder brackets and hinges for easy installation of the entire door.

External Truss

Schweiss hydraulic doors are pre-built with a special bottom external truss that provides added strength and rigidity... very important in high-wind conditions.

One-Piece® Hydraulic DoorFrame

Provides an extended canopy in the open position. Door swings outwards when opening, requiring space for the door to travel.

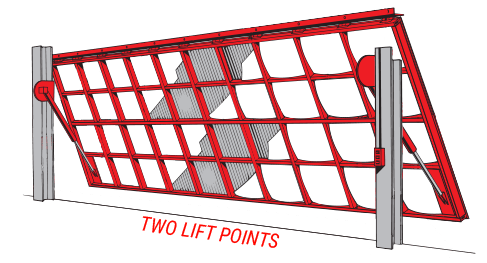

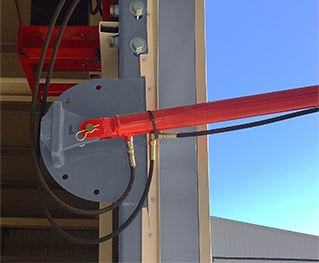

Lift Points - Two hydraulic cylinders

The One-Piece® hydraulic doorframe is opened with two heavy-duty hydraulic cylinders, one on each side of the door. Cylinders come with spherical bearings. The entire weight of the doorframe is transferred back to cylinder legs that pre-mount to the building column. A fully opened hydraulic door extends straight out from the building (Looks like a large airplane wing) exerting forces back to your building structure. The entire building structure must be designed to carry these loads.

WEATHERTIGHT

The doors are extremely weathertight. The hydraulic cylinders pull the door secure against the building!

Powerful Hydraulic Power Unit

Schweiss power units are a powerful, secure and simple solution to raising and lowering the doors. Each door consists of only three major components: the door (pre-hung with frame), two hydraulic rams and hydraulic pump.

Emergency Backup

All hydraulic door power units come standard with tractor fittings, which allows your door to be opened in case of a power loss!

Heavy-Duty Hinges make the door

Hydraulic doors are designed with one set of heavy-duty hinges that carry the entire weight of the door. The Schweiss hinge design is superior.

The Schweiss design, with the extra long pin, not only reduces the sstresses ina ll the components of the hinge but it spreads the forces over a broader portion of the door. The Schweiss hinge design is robust. It's all about surface area. The more surface area you have in the hinge design, the lower the stresses will be in all the components. The Schweiss hinge design has 22" of surface area that will give you years of service no matter what size door.

Greasable Door Hinges

Schweiss is the only manufacture that has grease zerks that allows the owner of the door to grease the hinges for longer life.

Bifold

You get more . . .

The bifold doors have been around for many years and the unique design has made Schweiss Bifold Doors the leader in the market. Schweiss Doors has design features built into each door that make the them stand out in a class of their own. Below we list some of the designs that make the Schweiss Bifold a good choice.

Open Evenly, Safely and have greater longevity with multiple "Lift Straps"

Our patented heavy-duty lift straps raise and lower the bifold doorframes using multiple lift-straps evenly spaced across the entire doorframe to

provide an even lifting force. The nylon lift straps rated at 29,000 lbs. tensile strength attach to the bottom of the doorframe at multiple locations to keep the door even when lifting while never binding or making noise like an outdated cable-lift door.

| New Lift-Straps | • | Lift-straps raise and lower the door. |

| Less maintenance | • | Lift-strap doors DO NOT require pulleys or cables, have fewer parts, fewer problems and less maintenance. |

| FasteR | • | Lift-straps wrap in a spool to raise and lower the door, increasing operating speed. |

| Quiet | • | Lift-straps operate very quietly. |

| Safety | • | Lift-strap are safer than outdated cables. |

Latch-Strap - New

Schweiss designed a new auto-latch that uses a strap instead of steel cables to secure the door in a closed position.

The latch-strap is one of the improvements that sets Schweiss Bifold Doors apart from others who still use outdated cables to latch their door.

The latches secure the door against the building and provide an extremely weathertight seal!

WEATHER TIGHT

The doors are extremely weathertight. The new strap-latch pulls the door secure against the building!

Advantages of a Two-Piece

Bifold DoorFrame

Bifold doors have two sections; a top half and a bottom half that provide advantages.

A two section door hangs out half the distance of other style doors.

Extending half the distance off the building means less stress on your building structure.

When a bifold door opens, the door frame folds into a "V" or a wedge acting as a huge truss supporting each of the two bifold door sections. Very Strong!

SPACE SAVER

The fact that bifold doors fold in half instead of just swinging out, allows for more open ramp/vehicle space in front of the hangar. It also allows the full use of the width of the hangar, making the entire end wall a door.

PROVIDES SHADE IN THE SUMMER

Bifold doors form a canopy when open, that provide shade. Another important feature is it allows moisture to run off the open door.

Wedge On A Bifold

The taller the door wedge, the less stress it exerts onto the building structure. The wedge itself is the strength in the design.

Hinges

Bifold doors are designed with two sets of hinges to share the loads of the doorframe.

Double set of hinges add strength and safety.

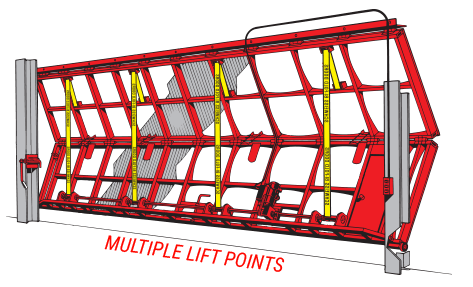

multiple lift points:

The multiple lift points are spaced evenly across the entire width of the doorframe that attaches to the header / building structure, carrying the door loads more evenly to the attaching points on the building making less stress on the building. Example: 40 ft door will have 4 lift points.

Weather Elements

It's important on any door to be able to shed the moisture that can accumulate on an open door. Water or snow must be able to flow off the door.

Bifold doors, when in the full open position, have a slight slope to provide drainage to the door in all positions.

The unique design is standard on all Schweiss bifold doors... because of the natural slope built into the bifold door wedge.

YOU GET MORE... With a Bifold Door

Internal Truss . . . standard

Bifold doors are manufactured with an internal truss that's mounted on the inside of the doorframe for added strength and proper wind loading on the door.

Benefits of an Internal Truss

Nice, clean look inside.

No lose of headroom.

Located on the inside of the doorframe.

Located out of the weather elements, protected.

Safer, not a tripping hazard . . . Up and out of the way of people walking by or near it.

Won't collect debris/snow.

Snowplow won't run into it.

Provides added strength to the doorframe.

Allows for proper drainage to the door since the truss is inside and not outside acting as a dam.

Optional: External Truss for Bifold Doors

Located at the center of the door.

Hydraulic Door Secrets

Learn the Insider Designs of the Hydraulic Hangar Doors

DEAR CUSTOMERS,

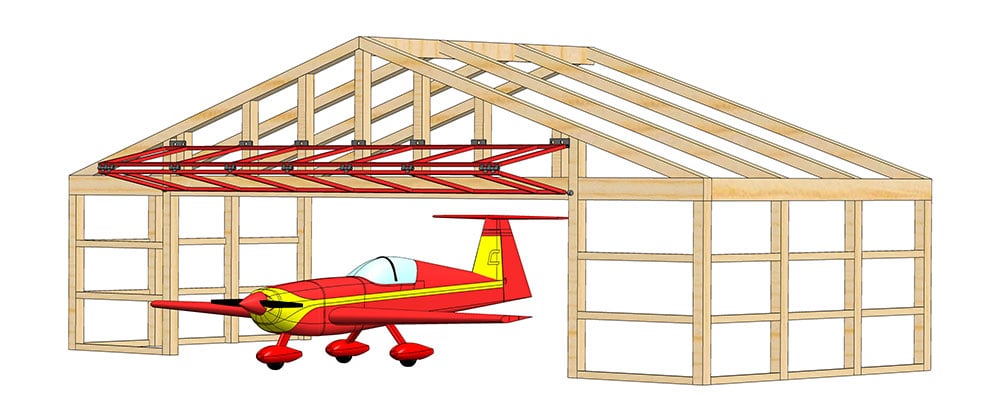

The Aircraft Hangar Building is only as good as it's "Door." The door you choose is a huge decision. Let Schweiss help you make this choice. Explore the different hangar door designs. Schweiss is willing to share with you the detailed door comparison of each design so you can make the correct decision and select the door that works for you.

If you're thinking about buying a door for your aircraft hangar we are about to educate you on many important features and decisions you have control of! There are no insider secrets with Schweiss Hydraulic Doors we put all our cards on the table.

HANGAR BUILDING MANUFACTURERS SOMETIMES DO NOT OFFER

YOU CHOICES WE'RE ABOUT TO TELL YOU...

Did you know that a custom built door for your aircraft hangar does not cost as much as the hangar itself? The word custom can be deceiving. The major hangar manufacturers quote the price of the door included in the overall building quote. Have your building company separate the door package prices from the building quote. Schweiss wants you to have an affordable new hangar building with a beautiful automatic hydraulic or bifold door of your choice. You do not want to find out later that you could of bought the exact same hangar from the same manufacturer less the door and saved thousands. When someone is overcharging you thousands of $$$ on a door alone, do your homework before shopping!

Like a customer once told us, "I found out that...I was never given a door choice!"

SAVE THOUSANDS ON YOUR AIRCRAFT HANGAR!

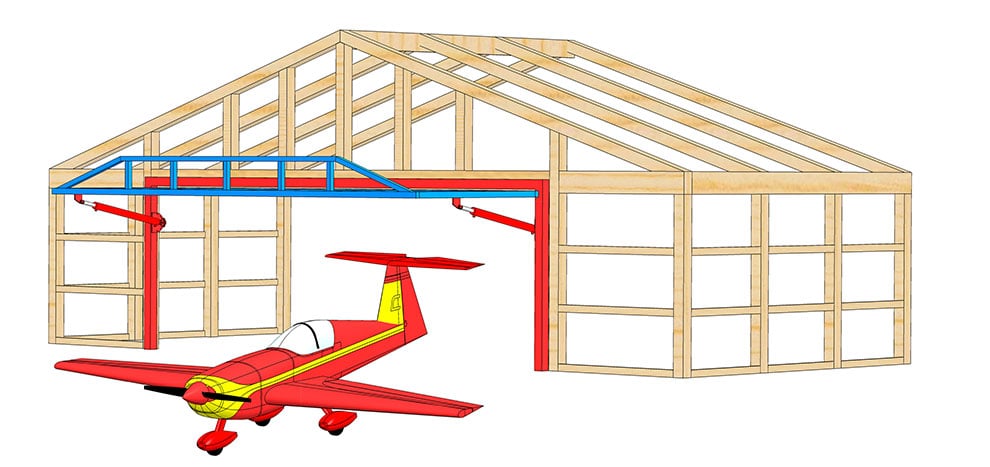

Some building designs may be underbuilt and end up costing the end-user of the door more money. Schweiss provides the building manufacturer and door owner with a full set of detailed Spec Sheets that provide the weights and moments that your door applies to the building. It's important to build the building endwall / sidewall to accept the door of your choice. Before fabrication of the hangar building, Schweiss can provide the building manufacturer with the Spec Sheets. Take no short cuts! Do it Right the first time!

Like a customer once told us, "To make matters worse, I found out that... The building endwall was not designed for the door."

Knowing about different door and building designs can save you thousands of dollars. For example, did you know that you can put a high quality hydraulic door on your aircraft hangar and save thousands on your building cost alone! Schweiss is also going to show you detailed pictures and technical drawings of doors so you will better understand the hangar door yourself and save thousands when buying your prefabricated building.

Schweiss Offers . . . Customer Choices

We're about to discuss the two different airplane hangar door designs. Schweiss manufactures the best two superior door designs available. Each have advantages and differences and some are better suited for specific climates and applications than others. Let us explain the many advantages and facts. This will give you a helpful overall guide to selecting the door of your choice to accommodate your building with the intention of getting the most for your dollar with the best door design money can buy.

BUY THE DOOR THAT BEST FITS YOUR BUILDING!

Most airplane hangar building manufacturers will only tell you about the door they happen to sell. And guess what... you may end up buying a door that doesn't fit your needs!

Most people only know about one or two designs or they talk to a salesman who tries to sell them a specific door regardless of whether it's the best suited for their specific situation. Each door is different and each has its place. Each door has a different price.

Don't get caught up buying too low of a sidewall building height. Yes, it's great to save money, but it's also important to have some wiggle room when it comes to clear opening height. If you max the building out and need more headroom at a later date, you'll find it hard trying to elevate the building because your rafters are not high enough from the start. Think about headroom and plan for the future.

Superior Design . . . Original "One-Piece" Hydraulic Doors by Schweiss

The hydraulic door is one of the most recent door designs available. This "one piece" door pivots at the top, requires only one set of hinges horizontally and swings open forming a large canopy in the front of your building. It is actuated by two powerful hydraulic cylinders with one hydraulic ram on each side of the door. The Schweiss hydraulic door is one of the best automatic door designs available today. Schweiss has always offered people choice's and our superior hydraulic door does just that!

Listed below are many advantages and facts we'll share with you

customer comments . . . "about Hydraulic doors"

Parking Near

"Nothing can be parked anywhere close to the door when opening."

"When I ordered my hydraulic door I got them to put two windows on the left side so when I am standing in front of the controls I can see outside and make sure the area is clear. I work for a guy that has two hydraulic doors on his new shop."

"They need more 'kick out' area when opening than a bifold."

"The 'No Parking' area with hydraulic doors is to make sure that nothing is in the way. Paint a yellow line to make sure you never pass it. They started to open the door one day and someone had parked a pickup in front of the door, they said it lifted the front wheels of the truck off the ground with no damage to the door.

"I didn't want a one-piece door because I drive uphill to get out and might hit the door with something tall I might buy some day?"

"Our airpark has one hydro swing door and the board will not approve another due to the fear that an aircraft will taxi into the open door. Several owners have been very vocal in opposition to the one hydro swing door on the field."

"Be extra careful with the one-piece tilt up doors. They swing way out and can hit things left some distance from the door. There are things you can't see from inside the hangar when you activate the door. Pulling a plane or vehicle up and parking in front of one of those hydraulic doors can be very expensive when someone inside decides to open the door, and out she comes. The crunching sound is an expensive one."

Driving By the Front of your Building - Airplanes Parking Near

"Just wanted to touch bases with everyone concerning hangar doors. Over the last couple of years too many people have shut their hangar doors on their plane. That means they are leaving planes way too close to the door edge sometimes on the inside, but usually these incidents happen when the plane is on the outside of the door."

"To help avoid a problem with the moving door colliding with an airplane we have marks painted on the outside apron in front of the doorway - Stay Back"

Snow & Cold

"With all the snow we get in front of the door in some storms, I doubt the hydraulic door would be able to push it out of the way when opening. Then we would have a problem."

"With our Hydraulic Doors, we have never had an issue with snow. Granted we never have over a couple inches at a time.

"I think hydraulic doors cost a little more. I like mine but it's not as good in snow as a bifold."

"With the hydraulic doors, make sure that when the power goes out you have it setup to run off your tractor hydraulics. If you get a lot of snow, it is always a hassle to clear the doorway before you open the door."

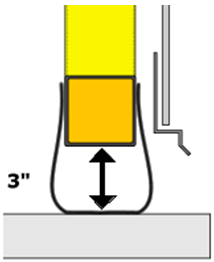

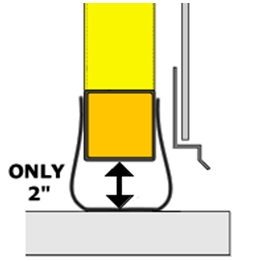

"We sometimes get significant frost heaves during the winter up here in Canada. The bottom external steel truss of the door only has two inches of clearance above the ground and my outside ramp sometimes heaves up about an inch which makes it a bit of a tight squeeze for the rubber gasket along the bottom. So far it hasn't caused any real problems but I would say the door is probably better suited to warm climates where you don't have to worry about frost heaves. Bifolds lift up rather than push out so there is no need to worry about clearance."

"The hydraulic doors are nice but it looks like it takes a lot of extra structure to support that huge door sticking out in the wind. If you get a bunch of snow up against it you have to move it before opening."

"The bottom truss is a catch-all for the leaves and debris. If I had to do it over again I would order a hydraulic door with an internal truss."

"On each end of my external truss we installed flags so the snow plow would not bang into it!"

Forces on the Building Structure

"The hydraulic door was sure moving with the wind blowing! I thought it would break, loosen or wear something out soon; either on the door or the building. The hydraulic swing door is great. I would prefer that over the bifold but the hangar needs to be much stronger and well engineered."

"The hydro-that swings has few points of attachment to the building; a sail in search of wind. Something to consider for those of you planning on a hydraulic swing style door is that the load on the doorframe is huge when the door is open. I have seen this in action. A friend up in Oregon has had to redo the doorframe on his hanger because the king studs were being literally pulled out of the wall at the top. If I were doing some kind of one-piece swing-up door, I would be sure to use steel "I" beams for the door framing and be sure things are engineered for all the weight load cantilevered off the king stud when the door is opened."

"The hydraulically operated doors that I've seen put some tremendous forces onto the structure during the door opening cycle that would be much better handled with a strap operated bifold door."

"There were a couple of things I didn't expect - one is that opening the door creates a pretty significant vacuum inside as the hydraulic rams push 700 square feet of door away from the building. I have to open a side man-door to allow air into the building otherwise there is a risk of imploding the other windows in the building."

Over the LifeTime of the door

"These doors are nice and fancy when they are new but after seeing older ones in operation eventually seals and hoses begin to seep and I have seen walls with oil from top to bottom."

"Cold weather and hydraulics don't get along. If your building isn't heated, hydraulic hoses can break. I don't know about the safety features now but before if one broke the door was coming down FAST!"

Hydraulic Advantages

PRE-ASSEMBLED, PRE-WELDED AND DELIVERED PRE-HUNG

WITHIN ITS FRAME FOR EASE OF INSTALLATION

Provides additional strength to your buildings

Makes installation easy - Lift the Framework and Door into place all in one step

Framework is Standard on all Schweiss Hydraulic Doors.

SAVE ON BUILDING COSTS

Zero Headroom Required - Lower your building cost by lowering your building height. That alone will save you thousands of dollars.

Remote Controls are available to Operate your Door

Lets you open/stop/close your hydraulic door from any vehicle. Customers really enjoy this feature!

Warning: All doors equipped with remote operators should have a warning system to alert persons in the immediate area that the door is moving.

Parking in Front of the Door

Hydraulic doors that are "One Piece" and swing out when opening require more open ramp space in front of the airplane hangar for the door to open. You can't park a vehicle or aircraft close to the door. Schweiss recommends you install a window within the hydraulic door so the door operator can view the doorway before operating the door.

P.S. If you park your plane or equipment too close to your hydraulic door opening you may hear some expensive noises when opening the door.

STRENGTH BUILT-IN

It's important to have a truss at the bottom of the hydraulic door to keep the door from sagging when it's opened. This same truss when located on the front side of the aircraft hangar door can collect debris and snow. Snow and debris must be kept clear from the front sides of the hangar for the doors to be able to open. Multiple truss options are available through Schweiss hydraulic doors to give you the clean look. Schweiss custom-builds each door!

DOOR IN THE OPEN POSITION

Door when opening, cantilevers outward, lying perfectly flat in the open position. Do not keep the hydraulic door open during heavy winds, snowing or raining conditions.

Hydraulic Door Safety

Schweiss hydraulic doors have built in safety features like velocity fuses in the hydraulic cylinders to prevent the door from closing in the event of a hose or line breaking. Flow control and soft shift valves located on the hydraulic pump allow Schweiss hydraulic doors to open and close smoothly preventing any jerky motion when operating your hydraulic doors. Schweiss doors are built with safety in mind!

Schweiss is a leader in the hydraulic door manufacturing. With the Schweiss Hydraulic door company there are no secrets...everything is explained upfront.

Add-Ons

Schweiss doors offer many features to make using your door easy to operate. Remote controls are a great addition to your door. With the press of a button, you can open or close your hydraulic door without ever leaving your vehicle. Entrance lights are another great add-on that can be positioned anywhere more light is needed when opening your hydraulic door.

When it comes to Schweiss electrical components we provide the best on the market. When using cheaper electrical components it will be more expensive and difficult to add upgrade equipment later on. Schweiss is not about cheap, your airplane hangar door will be the best. Buy Schweiss

Hydraulic doors from Schweiss use the best components to ensure a long service life for your door. By using steel parts and components your hydraulic door is sure to last as long as your building. Every component from the hydraulic pump to the cylinders are top of the line and Schweiss never cuts corners to save a buck. Schweiss gives you the very best they have to offer right from the start. Every aspect of the Schweiss hydraulic door is top of the line so there's no need to "upgrade" your hydraulic pump or electrical controls at a later date.

Only as good as the . . . Components

What a customer once shared with us... "A door is a door... Right? WRONG! Like many people, I thought all hydraulic doors were pretty much the same, but boy did I learn my lesson. A hydraulic door is only as good as its components, and workmanship, that's what sold me on the new Schweiss Hydraulic Doors. After helping a neighbor install and operate his "One Piece" Schweiss hydraulic door, that sold me right there and from then on I knew Schweiss Doors was the right choice for me! The Hydraulic Door Secret was no longer a secret. I proudly told my neighbors how happy I was with my Schweiss Hydraulic door."

Truly customized hangar doors can make life so much easier. The Schweiss Hydraulic doors let it happen with the push of a fingertip. Since the system is hydraulic, there are two powerful cylinders that do the lifting, no cables, pulleys, bearings, shafts - now that gives you clean looking door. The Hydraulic swing door being "One Piece" allows a weathertight seal, that keeps the weather out. The customized "One Piece" hydraulic doors are easy to install and no adjustments are necessary once they're in place. The Schweiss Hydraulic Doors can be installed on any building, best of all they still maintain the headroom requirement is only 5 inches. That is where you can save thousands of dollars by lowering the height of your building and still maintaining the headroom needed.

Let your next hangar door be a Schweiss "One Piece" hydraulic - it will give a little extra air conditioning and shade in the summer, give us a try.

Hydraulic Comparisons

Schweiss:

DISTANCE UNDER DOOR FRAME

SCHWEISS:

3" Distance under the doorframe

More Clearance

Allows for shifts in concrete

2" Distance under the doorframe

We offer choices

Some Other Brands:

OTHERS:

2" Distance under the doorframe

Best Designed Hydraulic System

Schweiss Hydraulic Pump

Unique Compact Design

Remote Control Available

Complete Electrical Package

Emergency Backup Tractor Fittings

Oil Filter & Gauges

Clean Design

Quiet Pump - With Standard Motors

Self-Contained

Powerful Hydraulic Power Unit

Quality...

Quality...

Quality ! ! !

If There Is A Failure Of A Hydraulic Component, The Door Needs To Stop Immediately!

Stopping the door completely in the event of a hydraulic component failure can be accomplished with a VELOCITY FUSE or a COUNTER BALANCE. The Schweiss Way

Restrictors or Orifices...

Have been used by some manufacturers as a safety feature.

WARNING

When others are using restrictors/orifices in the

dead end of the cylinder as a safety device...

- They may be setting you up for slow

motion disaster, Your worst nightmare!

Worst Case Scenario...

To have a door come down on a million dollar plane

or even worse than that, have the door come down

on people and put lives at risk!

Be careful... when phrases like these are being used to explain what happens in the event of a hydraulic hose/line failure using restrictors/orifices.

- “Gently coming all the way down...”

- “Controlled rate of descent...”

- “Coasting down...”

- “Preventing the door from slamming down...”

Some Have Said:

“In the event of a hose or line breaking, it will not stop the door from falling.

It takes 7 seconds for a door to come down when a hose / line breaks.”

Fact Is... That's Not A Lot of Time!

The door is coming down with no safety built-in to stop the door. Better clear the area!

When manufacturers use Restrictors on their cylinders...

- No safety built-in.

- Restrictors are not load holding.

- No way of stopping the door from coming down.

- Slow motion distaster... Your worst nightmare!

- The door won't stop if a hose/line fails (on the dead end).

- Door will come down if there's a failure, no matter what.

- The door is coming down on whatever is underneath it.

- Slowing the door as it comes down isn't good enough.

Did You Know?

If the manufacturer uses restrictors on the dead end of the cylinders, neither the restrictors nor the photo eyes will stop the door. You can't rely on the photo eyes to stop the door if a hose/line breaks on the dead end of the cylinder.

The Door Is Coming Down...

Restrictors Are Not A Safety Device!

Find out what safety devices you're getting on the hydraulic cylinders when you order your hydraulic door.

Call Schweiss

Ask yourself...“Do I know what I'm getting?”

“Is Safety Important To Me?”

Larger Cylinders With Spherical Bearings

“No one else in the industry offers this unique feature”

Only available on Schweiss Doors...

Doors Are Always Moving and Flexing

Spherical bearings reduce stress and wear on the cylinders, cylinders pins and clevishes during operation.

Hydraulic doors are large in size and just like an airplane wing, the doorframe flexes during operation. The hydraulic cylinders on each side of the doorway are connected to the doorframe and the building using spherical bearings. The spherical bearings accommodate the flexibility of the doorframe while at the same time allowing the cylinders to raise and lower the door without binding on the hydraulic cylinder pins and brackets. Spherical Bearings on both ends of the cylinder allow the cylinders to stay straight through the full range of motion.

Strong Words From Our Customer

“Soon as I saw and understood the spherical bearings design, it was a no brainer. I was immediately SOLD on the Schweiss Hydraulic Door!”

When Spherical Bearings Aren't Used More Stress Is Exerted!

- On the cylinders

- On cylinder pins

- On clevises

Cylinder Connection Points Don't Flex

Schweiss:

Some Other Brands:

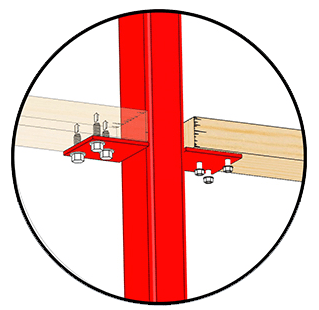

Top Cylinder Plate

Solid metal - pure strength!

The entire weight of the door relies on the Top Cylinder Plate to provide adequate strength to support the weight of your door in all positions.

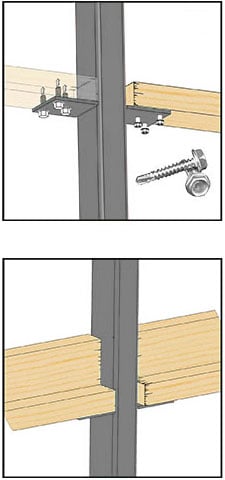

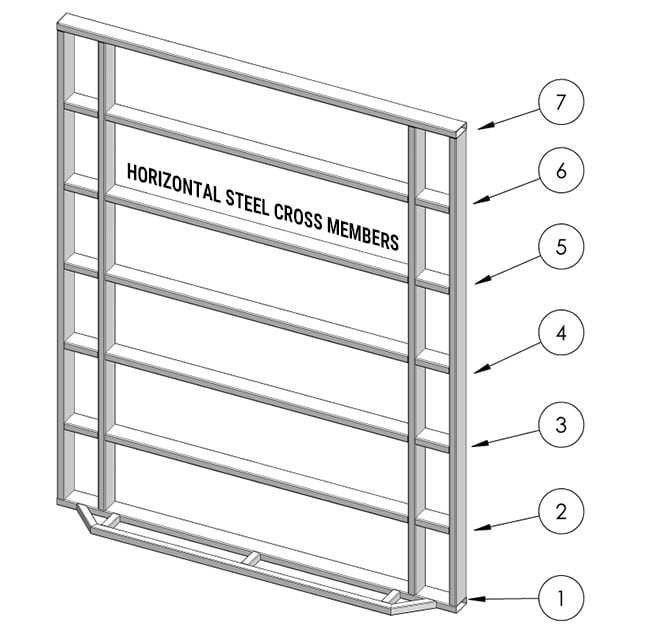

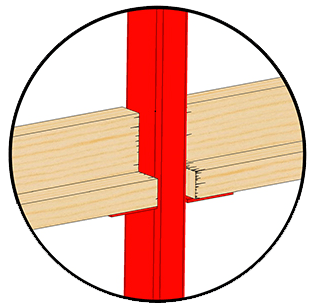

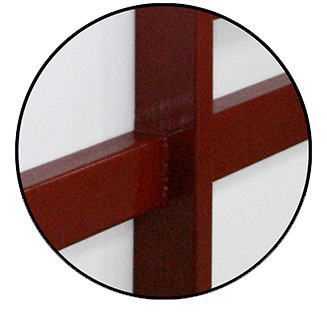

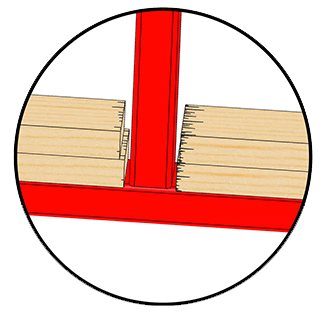

Steel Vs. Wood

Schweiss Uses Steel For Their

hydraulic doorframes Crossmembers

Schweiss Uses All-Steel Members

Strong Welded Connections

Internal Truss on this door External Truss is available

Assortment of different size metal pieces that need to be welded together!

Wood Horizontal Crossmembers

Tec screws or bolts used to fasten wood to the doorframe may work loose over time. Wood may shrink over time. As you open the door, it flexes due to the variable wind load and its own weight. The screws or bolts may shift in the wood, eventually working their way loose out of the wooden crossmember.

ONLY FROM![]()

New Hinge Design...

"Our New Wrap-Around Hinge Design Sets The New Standard For Hydraulic Doors"

Schweiss doorframes are designed with double push tubes that are tied directly into the wrap-around hinges that connect both vertical push tubes directly to the header tube. The advantage of double push tubes is that forces of hydraulic cylinders are evenly distributed to the doorframe and the wrap-around hinges.

"There have been hydraulic doors with hinge welds that failed, literally tearing off the doorframe and destroying the door," Schweiss says. "Our design team provided a durable wrap-around hinge with grease zerks that are accessible without removing the top rubber seal."

Its Own Self-Supporting Subframe!

Schweiss engineered a new robust hinge design that distributes the door loads evenly across the self-supporting subframe, greatly reducing stress on the building structure.

Schweiss Design

- Grease Points

- Removable Hinge Pins

- Superior Design

- Super Strong

The Hinges Sell The Schweiss Door

The Schweiss robust hinges are designed to withstand the door weights and hydraulic forces of the cylinders as the door opens.

Your door is only as good as its hinges! Take one look at the Schweiss hinges and you will clearly see the workmanship, strength and functionality of each hinge. The Schweiss hinges are big... strong... heavy-duty.

Grease Zerks

- • Schweiss hinges can be easily greased for longer hinge life.

- • SCHWEISS is the only manufacturer to offer hinges that can

be greased from underneath the door without removing the

top weather seal.

Removable Hinge Pins...

- • It's important to have removable hinge pins...

- • Hinge pins are not welded in solid on a Schweiss door.

- • Designed for easy maintenance.

- • All hinge pins are removable.

The hinge makes the door...

The weight of the door and hydraulic forces exert loads on the hinge while the door is operating.

So it had better be STRONG!

The unique hinge design incorporates heavy hinge plates that wrap around each vertical push tube for added rigidity. Without this wrap-around design, the doorframe members can be overstressed and begin to tear apart from door weight and hydraulic forces over time. This won't happen with a Schweiss Door!

Hydraulic doors operate with one set of top hinges. These hinges need to be strong enough to support the door weight and the hydraulic cylinder forces when opening; unlike a bifold door that shares the load between the top hinges and the center hinges.

What Door Customers Are Saying...

- “The hinges sold me.”

- “The Schweiss team hit a home run by putting grease zerks in their hinges”

- “Now that's a Serious Hinge, You guys have it figured out!”

- “Oh my, nothing comes close to it. Professionally done!”

- “Nothing on the market will even come close to the Schweiss hinge design.”

Strongest Hinges on the Market!

Strongest Doorframe on the Market!

- Greasable hinges on each and every hydraulic door

- Ability to grease the top hinges without removing the top rubber seal

Customers Welcome Greasable Hinges

HINGE SURFACE AREA

Hinge surface area is critical on large moving doors. Over the years, we all have heard of hinge failures on others doors. Large hydraulic cylinders are putting extreme forces on each of the outer hinges of the doorframe. Schweiss has designed and patented a robust hinge with more surface area to evenly distribute the loads of a moving one-piece doorframe. Look at the hinge surface area. The stresses on the very outer hinges are immense. With that being said, take one look at the patented Schweiss hinges and you'll clearly see the workmanship, strength and functionality of each hinge.

GREASABLE HINGES

It's very important to be able to grease the door hinges with a heavy viscosity grease. When grease is used on the hinges of a large moving door it avoids unnecessary wear and adds longer life to the hinge and the doors operation. It's a common manufacturing practice to use grease on the critical wear points and load points to avoid unnecessary wear just like in the industrial equipment world with implements such as payloaders, skidloaders and other industrial equipment that are being operated around the clock.

The new hinge design with grease points on every hinge segment enables owners - whether they be private individuals or commercial customers - to periodically grease their hinges from inside the doorframe without having to go through the cumbersome process of first removing the top rubber weather seal.

Advantages of Grease

Using grease on the hinges is a better method of lubrication.

Using grease on the hinges is the industry standard.

Using grease on the hinges makes for a quiet door.

Using grease on the hinges makes for a smoother operating door.

Using grease on the hinges extends hinge life

Greasable hinges last forever.

Look at the Schweiss hinge, it has more lubricated surface area to give you longer life

Others rely on bushing FOR LUBRICATION

Doors move and flex as they open and close. The forces on each hinge vary during operation.

Not all bushings wear evenly.

Bushing wear thin over time.

Worn bushings offer less lubrication.

Less hinge surface area to distribute the door loads across the door header tube.

No way to inspect the bushings when the hinge pins are welded in - Not removeable.

Almost impossible to replace the bushings when the hinges pins are welded in solid.

Hinges That Are Easy To Grease

. . . Only From

Schweiss:

Control Station

Low Voltage - 24 volt

Constant hold button gives you control at all times.

1 Step - A simple touch of the button lets you open/close/stop your door at any height. When door stops/ motor shuts off automatically. The motor automatically stops when you take your finger off the control station.

Remote Control Operated Door

Some Other Brands:

Toggle Switch

All Welded Steel Members

Schweiss Doorframes Have All-Steel Members With Welded Connections. . .

Welded Connections are Strong

Building header

A

All-steel members

with welded connections

B

- Door's subframe

4x6 header tube adds building/door support

C

- 4" x 5" side column adds extra support

D

- Horizontal members 4" deep - all welded connections

E

- Vertical members 4" deep

All-Steel Doorframes

All-Steel Doors are:

Strong

Cleaner looking

And allow more room for better R-Value insulation

Steel is a uniform material

All steel is a consistent grade and strength

Welds are strong and permanent

Welds never work loose

Schweiss uses 4" wide

steel members

When you purchase

a steel doorframe

from Schweiss

that's what you get...

ALL-STEEL !

Schweiss All-Steel Doorframe . . . For Less Money

Engineer's Words

Steel Vs. Wood

A 10-foot-long utility grade 2x4 is only capable of resisting a 23 mph wind. A 10-foot-long 2 x 3-14 gauge steel member is capable of resisting a 120 mph wind. Ask yourself how often the wind is greater than 23 mph? What do you think that would do to your utility grade 2x4.

Welded Connection Vs. Tec Screws or bolts

A 2x3-14 gauge steel member all around is good for about 120 PSF of wind. The steel is shop-welded, meaning no field labor is required. Welds are strong and permanent and never need to be adjusted. Every member of an all-steel door is positively welded in place.

Tec screws or bolts in the end of a 2x4 are good for about 40 PSF of wind if the screws or bolts don't split the wood. As you open the door, it flexes due to the variable wind load and its own weight. Tec screws or bolts used to fasten horizontal wood cross members to the doorframe may work loose over time. Wood may shrink over time. The screws or bolts may shift in the horizontal wooden cross member, eventually working their way loose.

Steel Vs. Wood

Quality wood is clearly identified. It is grade stamped "SELECT." It doesn't have large knots and splits. Even if the wood was "SELECT," it would only resist a wind of 12.3 PSF. All wood is not created equal. Steel is a uniform material. Steel is all a consistent grade and strength. When you get an all-steel door - including steel horizontal crossmembers- you know that the material quality is consistent.

Schweiss Uses All-Steel Horizontal Cross Members

Bifold Door Secrets

Popular Designed . . . Bifold Doors

Vertical Bifold Doors

The vertical bifold door hinges horizontally in the middle and is operated with an electric motor which spools the straps to lift the door. Vertical bifold is the most popular design for hangar doors. Surprisingly the vertical bifold door has been the people's door choice for many years and continues to be.

Listed below are many advantages and facts that we'll share with you.

BIFOLD DOORS . . . LIFT UP WHEN OPENING

Requiring less operating space in front of your building.

Makes parking directly in front of the door opening possible.

BIFOLD DOORS . . . Fold in half when in open position

Allows water to run off the open doorframe.

Creating a wedge that adds additional strength to an open doorframe.

Taking up less space in front of the doorway - since bifold doors fold in half which allows for more usable space in front of your door opening.

SPACE SAVER

The fact that bifold doors fold in half instead of just swinging out, allows for more open ramp/ vehicle space in front of the hangar. It also allows the full use of the width of the hangar, making the entire end wall a door.

DOUBLE SET OF HINGES

Bifold doors are designed with two sets of hinges to share the loads of the the doorframe.

Multiple Lift Points . . . Offer huge advantages

OPENS DOOR EVENLY!

Added safety factor when incorporating multiple lift points.

Evenly lift and support the doorframe.

The lift points are evenly spread throughout the entire width of the doorframe balancing the weight of the door evenly across the header / building structure!

Schweiss TESTED AND PROVEN " New LIFT-STRAPS "

For years bifold doors have been lifted and lowered by the conventional means of steel cables. Schweiss Doors have been using the popular, long-lasting lift-straps for over 28 years. Now 99 percent of our customers are demanding polyester lift-straps for this function. Why? Because lift-straps offer more lifting ability, won't fray or overwrap! The strength-to-weight ratio on straps is extremely high. The three inch straps are rated at 29,000 lbs, where 1/4" cables are rated at only 7,200 lbs. In addition, the safety factor on straps has well over the standard 5:1 ratio.

ADVANTAGES OF THE . . . " NEW AUTOMATIC STRAP-LATCHES "

This is what every door owner wants and needs. Unlike other latch mechanisms, the new design will firmly hold the door against your building in all positions; securing the door when open/partially open and will firmly lock the door when closed. It will offer added protection from wind gusts while the door is in any position during operation.

STRAPS DO ALL THE LATCHING!

Straps secure the door in the open position

Straps secure the door in the closed position

Adds protection from wind gusts while in operation

Latch-straps are rated for 29,000 pounds

SCHWEISS NOW HAS AN "ALL-STRAP BIFOLD DOOR "

Schweiss Doors is introducing an all-strap bifold door! Straps do the lifting and now straps do the latching too! It doesn't get any better than an all-strap door. The simplicity of the new latch-strap is truly amazing! Schweiss did away with all the cables, chains, sprockets, and pulleys; and it now has 90 percent less moving parts. This is a real game changer in the bifold door world! It doesn't get any better than an all-strap door.

SPACE SAVER

The fact that bifold doors fold in half instead of just swinging out, allows for more open ramp/vehicle space in front of the hangar. It also allows the full use of the width of the hangar, making the entire end wall a door.

ONCE UPON A TIME:

Older style bifold doors only came standard with . . .

Lift cables

Cable clamps

Pulleys

Springs

Manual latches

Other widgets

Bifold Advantages

EXCELLENT, PROVEN, SIMPLE DESIGN - THE MOST POPULAR DOOR ON THE MARKET

IT'S A FOLDING WALL - Clean, Neat Looking Door

Maintenance Free - Operation is relatively maintenance free

Less Moving Parts - with the new "Lift Straps," gone are pulleys and cables to service

Premounted electric motorized driveline attached to the bottom door panel.

STRONG DESIGN

When in the open position bifold doors protrude out half the distance, exerting less forces to your building structure and also less potential for wind or snow damage when open.

When a bifold door opens, the doorframe folds into a V ( sideways ) or a wedge acting as a huge truss supporting each of the 2 piece bifold door sections. The larger the door wedge the less stress it exerts onto the building structure.

LESS STRESS ON THE BUILDING

Because these doors are so large, the fact that they fold in half instead of just swinging out takes much of the stress off the front of the building.

MULTIPLE LIFT POINTS

Lift Straps are rated for 29,000 pounds and are used to raise the two-section folding doorframe. Bifold doors have multiple lift points throughout the width of the doorframe to evenly distribute the loads of the door across the building door header putting less stress on the hinges & doorframe.

TWO SETS OF HINGES

Double sets of heavy-duty hinges support the folding doorframes, two sets are better than one.

AUTO LATCHES

Auto Locks Included - Powered by the drive motor to lock and secure the door

Automatic operation makes opening and closing easy and painless.

NOW THE "NEW LATCH STRAP"

Pulls the door tight to your building ... weathertight

Simple Clean Design

Great Improvement ... No More Cables and Clamps

SPACE SAVER

The fact that they fold in half instead of just swinging out, Bifold doors allow more open ramp/vehicle space in front of the hangar for the door to open. Allows the full use of the width of the hangar, make the entire end wall all-door.

PROVIDES SHADE IN THE SUMMER

Bifold doors form a canopy when open that provide shade. Another important feature is it allows moisture to run off the open door canopy.

LOSE NO HEADROOM

Zero Headroom Required - Lower your building cost, this alone will save you thousands.

CLIMATE CONDITIONS

Bifold doors fold in half and are slightly angled to allow rain or snow to drain off the front of the door and not collect on top of it.

Bifold doors lift up when opening ( do not swing out ) -- Ice and snow is never a problem

Bifold doors do not require floor tracks that can fill up with debris or ice.

Best sealing door on the market - top / center / bottom gaskets

Mechanics of a Bifold Door

ELECTRIC POWERED MOTOR

Requires electricity to operate lifting motor. If the aircraft hangar loses power, the door can be operated with a manual Hand Crank

LOSE NO HEADROOM WITH A BIFOLD DOOR

With door completely open, the door folds into a 24" wedge

Example: Let's say your building opening is 12' clear, and you need a door clear opening 12' to maintain a 12' clear opening, you need to attach the door 24" higher than the clear opening.

Lose No Headroom, your building opening is 12' and your door opening will be 12' clear

THE NEW " LIFTING STRAPS " MAKE THE BIFOLD DOORS TROUBLE FREE

The new " Lifting Straps " that raise and lower bifold doors have virtually made the bifold doors trouble free. Straps increase the speed of the door as it is opening. Straps will lift your door evenly at all times, no adjustment needed. Your straps will never have uneven spooling, binding, jumping, moving. Straps are self-contained and fully guarded for safety. Straps are safe rated for 29,000 pounds each (Cables are only 7,000 lbs. each). Straps are superior to cables. Your new lift strap bifold door will work for many trouble-free years of use.

BIFOLD DOORS ATTACH TO YOUR ENDWALL AND SIDEWALL OF YOUR BUILDING

Schweiss includes specs with each door and provides the weights, forces and hinge locations. Bifold door forces are less on the building structure because the doorframe when open sticks out 1/2 the distance, and the bifold doors have multiple lift points ( 4 ) that evenly distribute the weight of the door across the building structure

REMOTE CONTROLS ARE AVAILABLE TO OPERATE YOUR DOOR.

Schweiss has designed an automatic door lock that actuates when the door is opened.

Schweiss automatic locks are a one step process. You hold the button to open the door and the autolatches release automatically and the door opens. Autolatches let you operate the door from one side of the door opening, saving costly mistakes. Unlike manual latches where people forget to unlatch before hitting the open button.

TWO SETS OF HINGES SHARE THE WEIGHT OF THE DOOR

Bifolding doors are made up of two equal doorframes that hinge horizontally in the middle and at the top of the door. Bifold doors allows the doorframe to be shorter in closer to your building in the open position. The further the doorframes are away from the building structure the greater stresses are to your building. With a Bifold door the stresses are minimal, because a bifold door hangs out half the distance. The double set of hinges share the weight of your door which all equates to longer door life.

SECTIONS: BIFOLD DOORS ARE TWO SECTIONS

Bifold doors hinge horizontally in the middle and at the top of the door. Bifolding doors are a two-section doorframe allowing the doorframe to be in closer to your building in the open position. The further the doorframes are away from the building structure the greater stresses are to your building. With a Bifold door the stresses are minimal, also the double set of hinges share the weight of your door which equates to longer door life.

MOST POPULAR DOOR ON THE MARKET

Vertical bifold doors are the most popular design for aircraft hangar doors. Vertical bifold doors are the least expensive door style to buy.

Bifolds . . . Just Keep getting Better!

The best bifold door secrets are no longer secrets. People are catching on fast to the new strap lift design by Schweiss. Bifold Doors are proven and with the lift straps they are even better. Bifolds are very adaptable when it comes to attaching your door to the building structure. Only after I had used the new bifold door did I realize how unique of a design it truly is. All my neighbors are wanting my strap door.

Today's new lifting straps, that doors, have virtually made bifold. Your new lift strap bifold door will work for many trouble free years of use. Only after talking with many satisfied Schweiss Strap door customers did I realize Schweiss is truly the industry door expert. Cheaper airplane hangar door designs are not what Schweiss offers ...Schweiss provides a top notch bifold door system. Schweiss doors are are up front with the information that they provide to each and every customer, keeping customers in the loop at all times on the latest and greatest door improvements that are available.

Schweiss is on the cutting edge of door manufacturing offering detailed door information that is supplied to each and every door owner and building manufacturer When considering buying or building an aircraft hangar, these special specs will save you time, money and give you the end product you will be proud of!

KNOW WHO YOU'RE DEALING WITH . . .

A WEB SITE MAY APPEAR ACTIVE, BUT . . .

- Nobody is returning your calls

- Not able to speak to an employee of the company... just an answering service

- Unable to get service

- Maybe it's used to

collect deposits

BE CAREFUL!

Scenario... How a door purchase could easily go south on you! Keep in mind these negative scenarios when selecting your next door so you're not caught up in any of these situations on your next door purchase.

Memory Lane

Take a trip down memory lane, few or more short years ago, door customers were losing deposits, company went belly up, leaving customers without service, doorframes tearing apart and no company left for support. How long does it take to forget about a $10,000.00 deposits lost? Shorted cylinders and the hydraulic power units!

Know who your dealing with, nobody likes to lose door deposits!

Smart Buyers...

Smart Buyers...

Smart Buyers...

KNOW WHO YOU'RE DEALING WITH . . BE CAREFUL

Do your homework! Google around and understand the company you're dealing with!

How long has the business been in operation this time? What went wrong the first time? Same name? Same owners?

Do they actually manufacture their own doors or outsource everything?

Where did they say it was manufactured? Find out!

Tips on how to get companies to answer " Your " Phone Call

It speaks for itself when others DO NOT take " your " phone calls.

Demanding payment in full before receiving the entire door shipment . . . is a red flag!

The Good News: It sounds like we finally have a delivery dare - Only to find out when the door was

delivered it was missing the major components, like the hydraulic cylinders and pump.

Hang onto your checkbook until you see the door... Seeing is believing!

Doorframes are Delivered Now . . . But Missing Components

"What good is a doorframe that's missing cylinders and pump?"

Smart Buyers

Pay only 25% down... Not a nickel more until the door shipment is complete, Including the Hydraulic Package.

Payment Method . . . Use Your Credit Card... Only

The credit card companies will refund all of your money if you don't recieve your door on time!

Paying by personal check has more hoops to jump through to get a refund !

You Usually get what you pay for...

You know cheap and good don't always go in the same sentence.