Schweiss Doors of Hector, Minnesota, has completely raised the bar in terms of hydraulic and bifold doors for aircraft hangars, and commercial and industrial use.

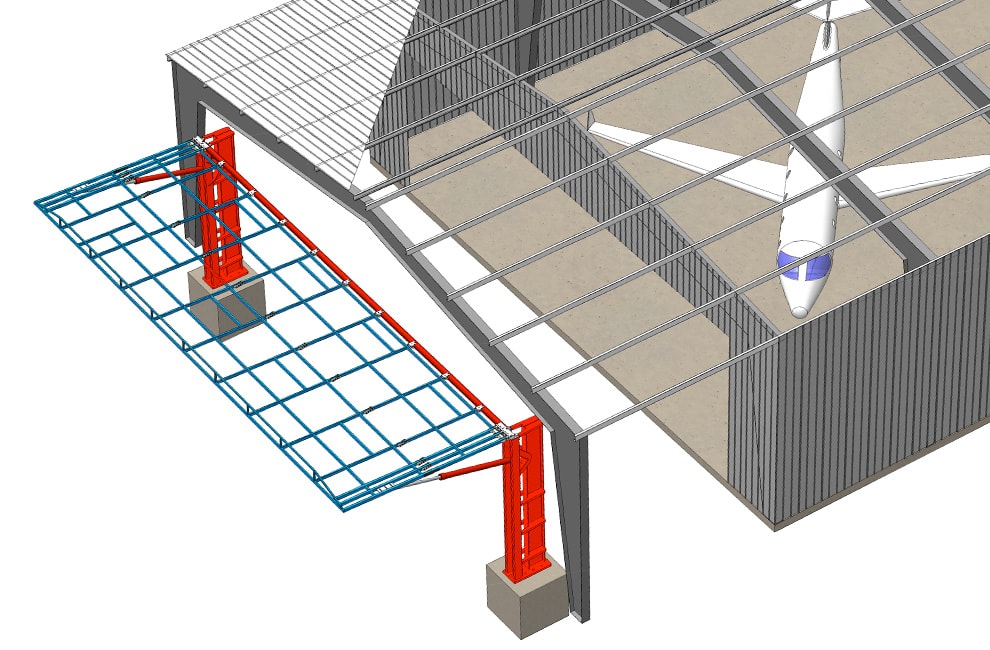

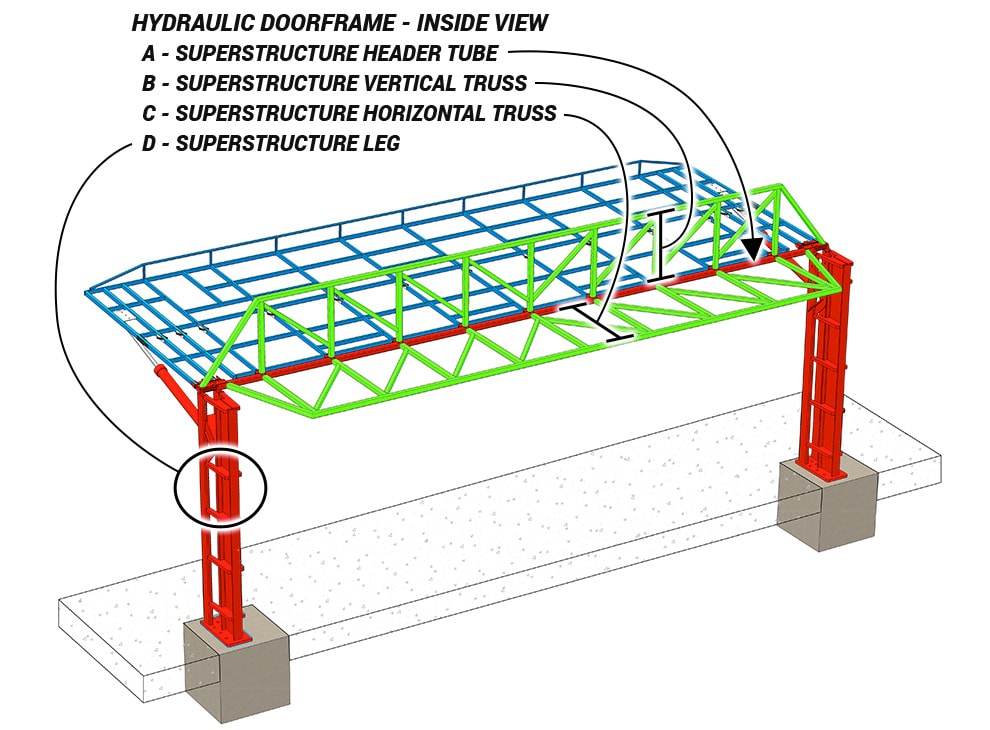

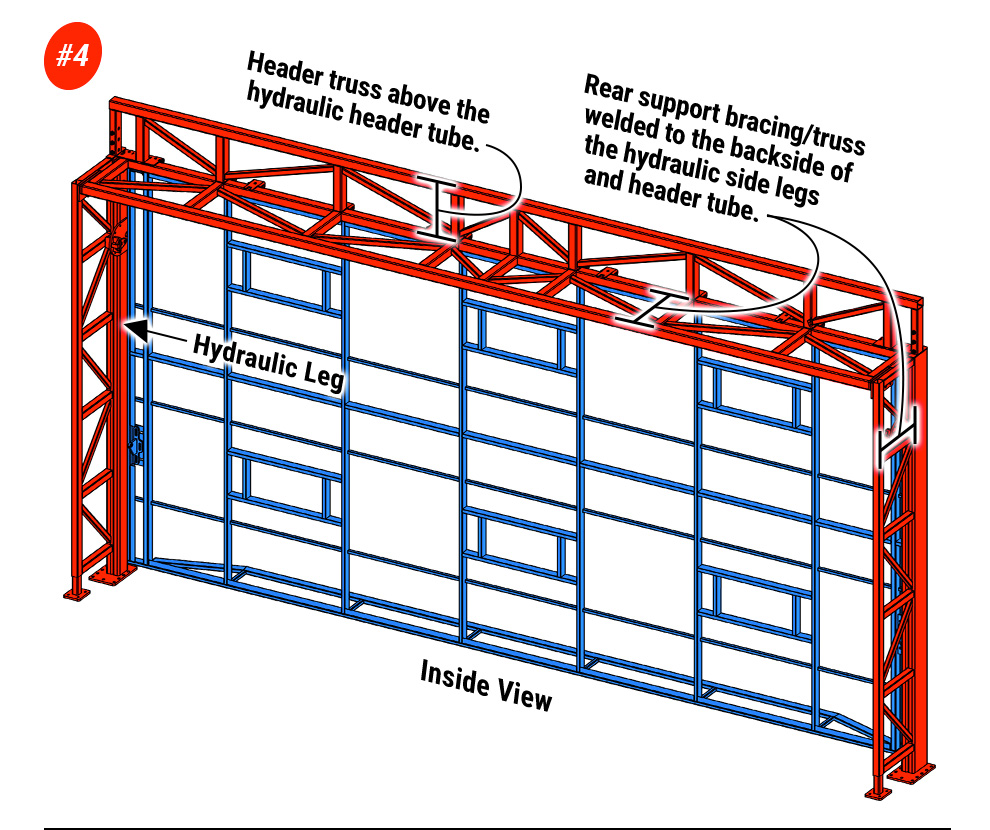

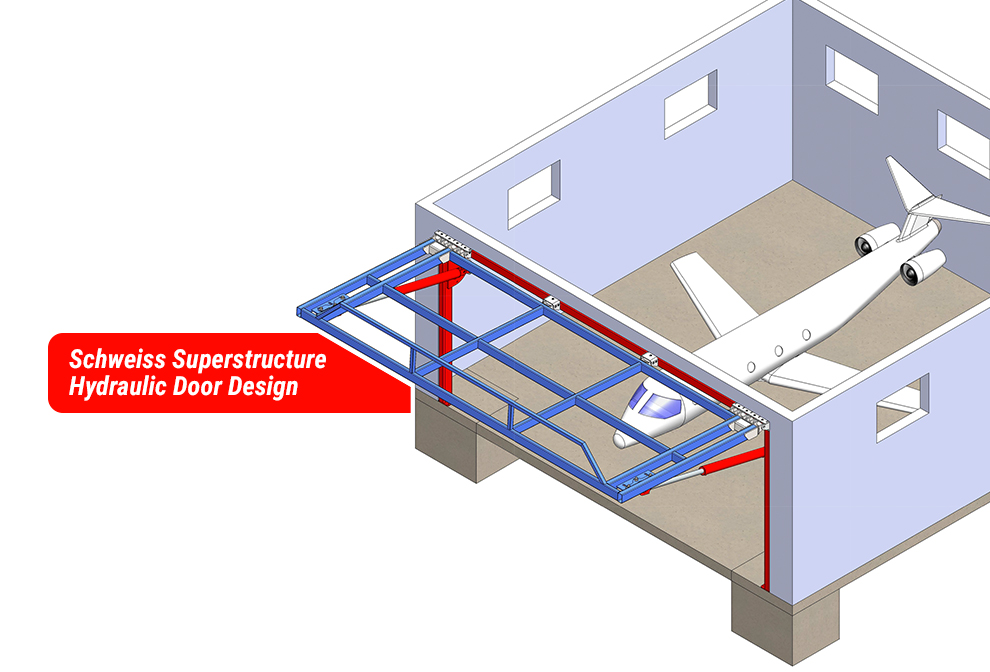

The new “Schweiss Superstructure Triple Leg Stand-Alone Door” is the only one of its kind. This trailblazing tripod leg design transfers the weight of the door to the footings that support it, eliminating the need for additional side columns from the building manufacturer, significantly reducing building costs.

The free-standing door has its own superstructure

framework attached that can be added to the client's new or existing building. It's all self-contained, so a retrofit is easy. This hangar door is so strong, yet so simple, that it requires nothing more than a common framed opening.

The stand-alone design eliminates the need for the building manufacturer to utilize a building truss or header to support the door on the building structure itself.

"When you're designing a door, build a new model that will make

other existing door models on the market obsolete."

"Schweiss has done that!"

Self-Supported Hydraulic Door Design For Your Buildings!

Schweiss has completely raised the bar in terms of hangar doors for general aviation and commercial jet hangars. We apply common sense and an innovative approach to provide you the right hangar door solution for your building. Schweiss realizes it's important to understand what impact the hangar door will have on your building. Schweiss offers all hangar manufacturers choices when designing their buildings.

Schweiss has the capability to manufacture a hydraulic door and framework that's designed to help support the building structure. It is a freestanding hydraulic door that has its own superstructure framework attached and can be added to your new or existing building structure. It's all self-contained so a retrofit is easy. This hangar door is so strong, but yet simple, that it requires nothing more than a common framed opening.

A Schweiss superstructure doorframe mounts on the 'New Stand-Alone "Self-Supported" doorframe; eliminating the need for the building manufacturer to utilize a building truss or building header to support the hydraulic door on the hangar structure itself. This means you can reduce building costs significantly and gain headroom; saving everyone dollars.

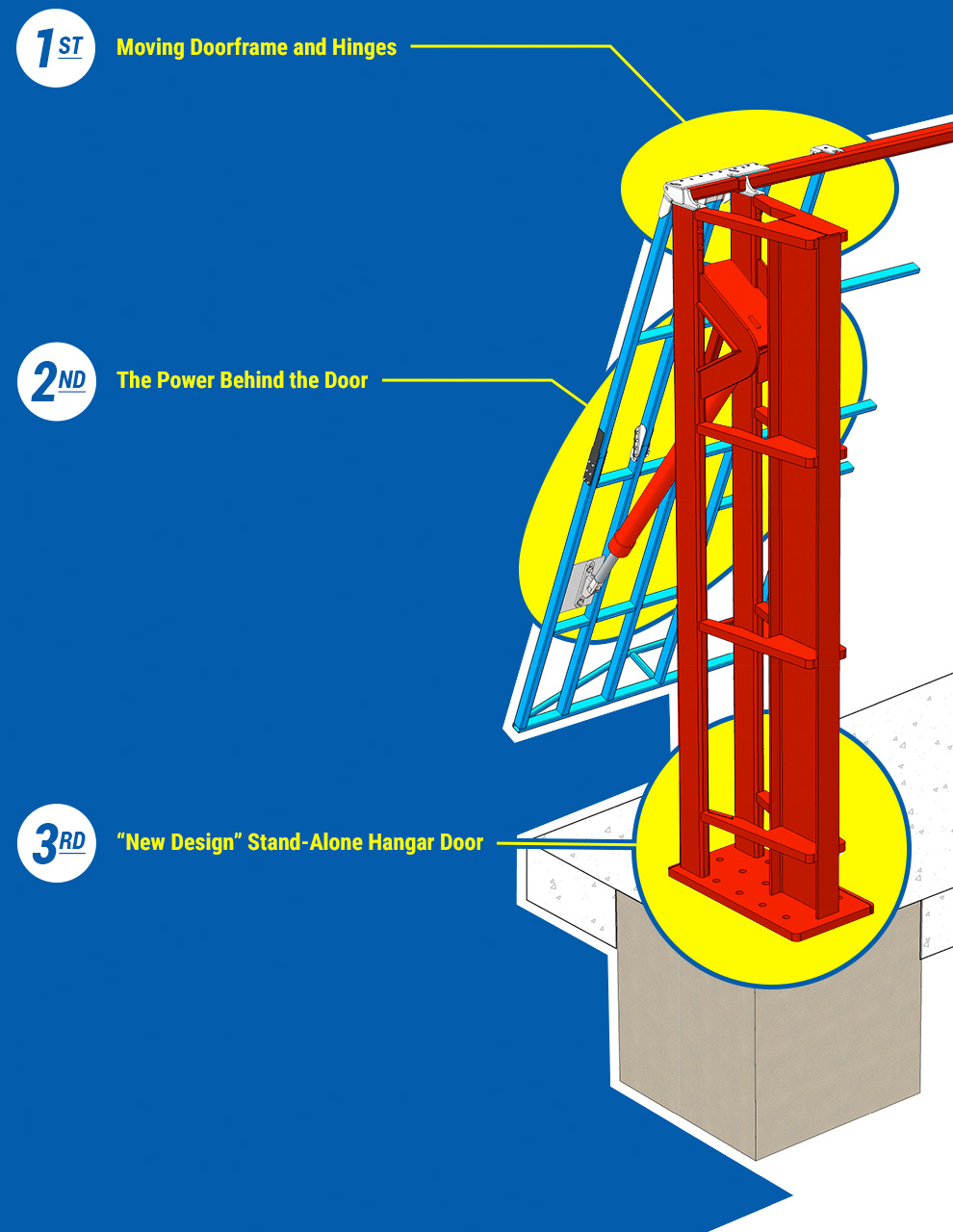

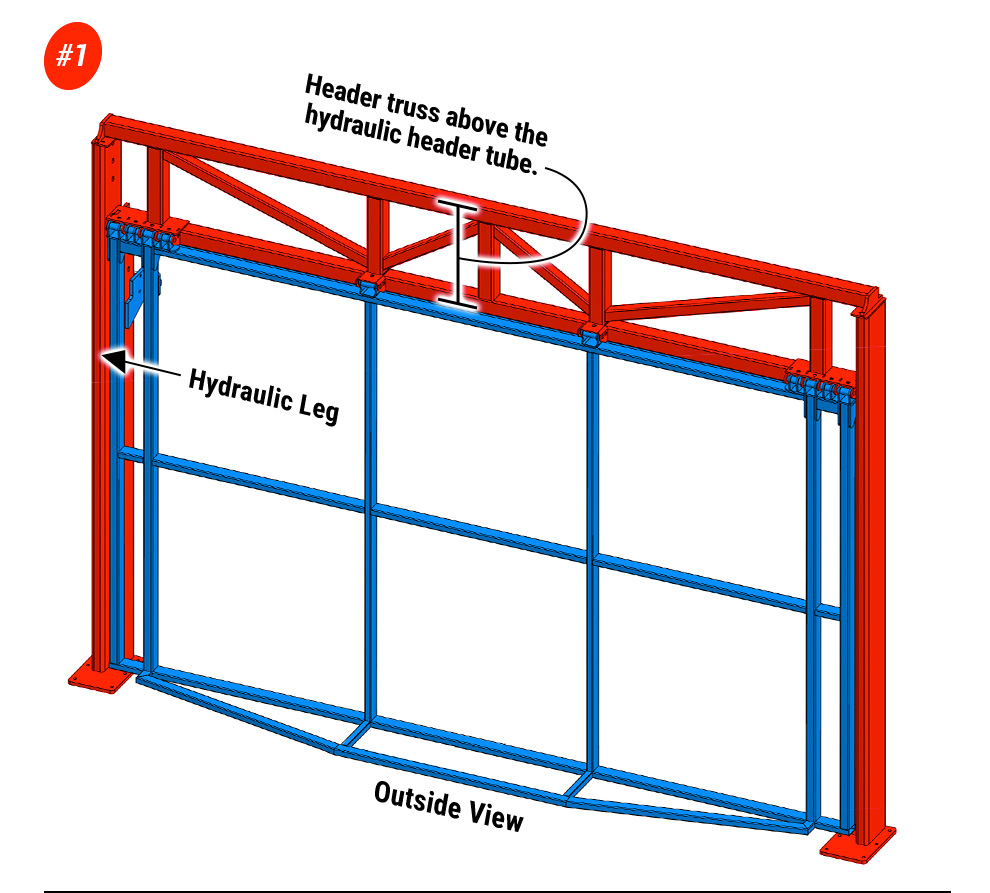

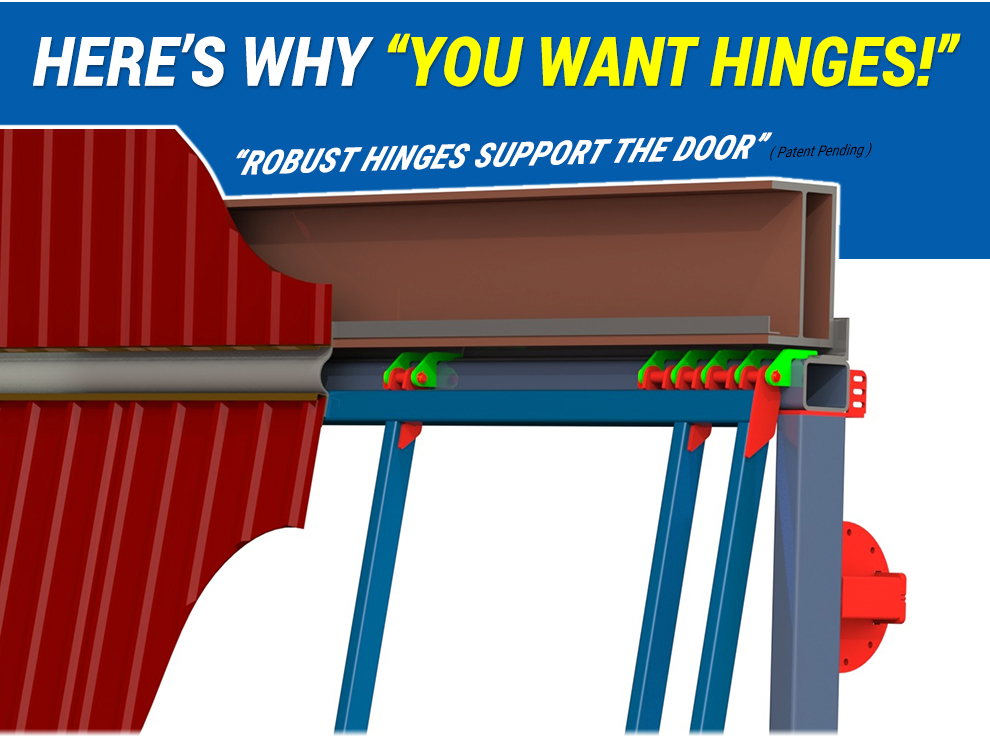

Robust Hinges . . . Gives the door stability in all positions

Schweiss Patented Hinges - Our proprietary robust hinge design connects the moving doorframe to the overhead structural subframe, providing a considerably stronger and greater surface area for distributing the load of the moving door evenly. The hinges and subframe provide the structural strength that carries the weight of a large moving doorframe! Robust Hinges have easy-to-grease zerk lubrication and removable hinge pins for extended service life.

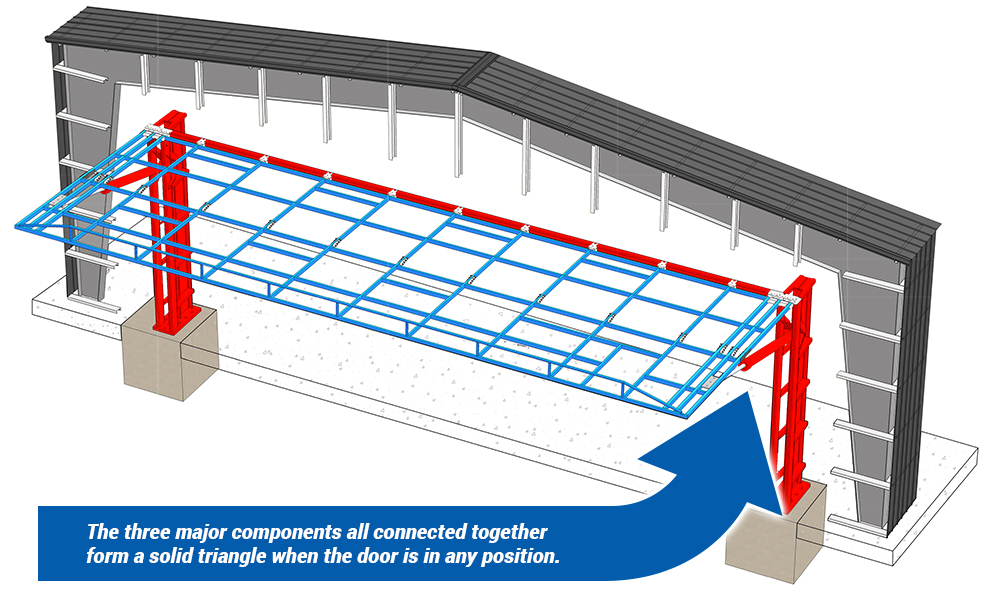

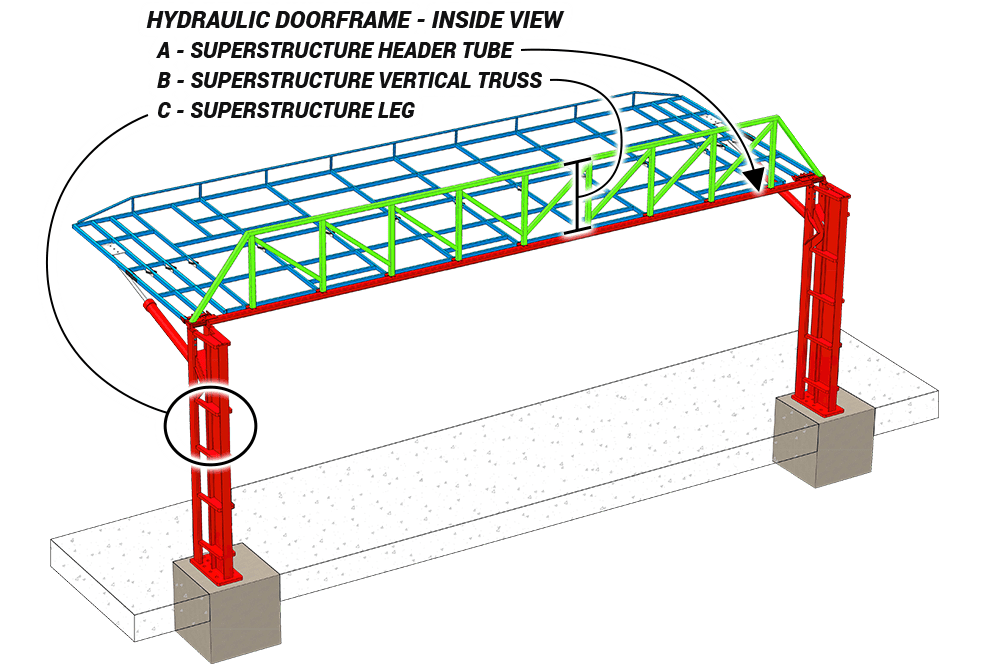

Three . . . Major Components

Make the Door Better / Stronger / Safer

Hydraulic doors have three major components, the cylinders, the doorframe and the subframe header. The three major components are all connected together to form a solid triangle when the door is in any position.

By connecting all the major components together it comprises a huge structural advantage and makes the door operation and installation strong and stable.

The three connected components below are what gives our door stability in all positions!

Connect to the overhead structural subframe - that includes a

robust hinge design providing considerably greater surface area

for distributing the load of the moving door evenly. The patented

hinges include easy access greaseable lubrication zerks and

removable hinge pins for extended service life.

Hydraulic doors have a huge advantage, by utilizing the major

components for stability! The major components add stability to

the door in all positions and allows for flexibility of the door and

frame without binding on the cylinder pins and brackets. With all

the major components connected, it makes the door so much

stronger and stable in all positions at all times.

Support the sides and ends of the door in all positions.

Spherical bearing connecting cylinders on each side of

the door to the doorframe accommodate horizontal

movement or deflection. They also allow for flexibility

of the door and frame without binding on the cylinder

pins and brackets.

Heavy-duty cylinders are connected to the door-

frame and massive tri-pod legs. They are supported

by heavy-duty hinges that connect to the doorframe to

the subframe header to better support the moving

doorframe in all positions. By connecting all the

major components together it creates a huge

structural advantage. A solid triangular connection

gives a moving door support and accommodates

horizontal movement or deflection to the moving

doorframe in all positions, making the door

operation and installation strong and stable.

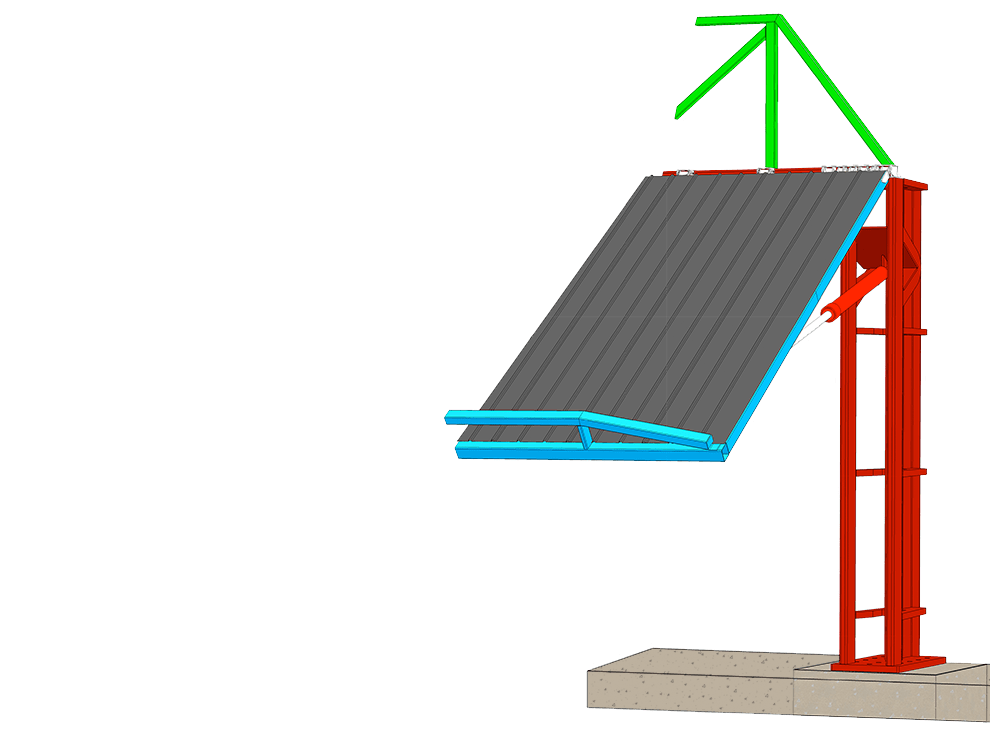

Attach to the Subframe Header providing the

structural strength that carries the weight of a

large moving doorframe! The Tri-pod structure

supports the door and hydraulic cylinder eliminating

column twist, distributing the door weight and loads evenly

into the concrete footer - the door loads are transferred to the

floor during operation, not the building.

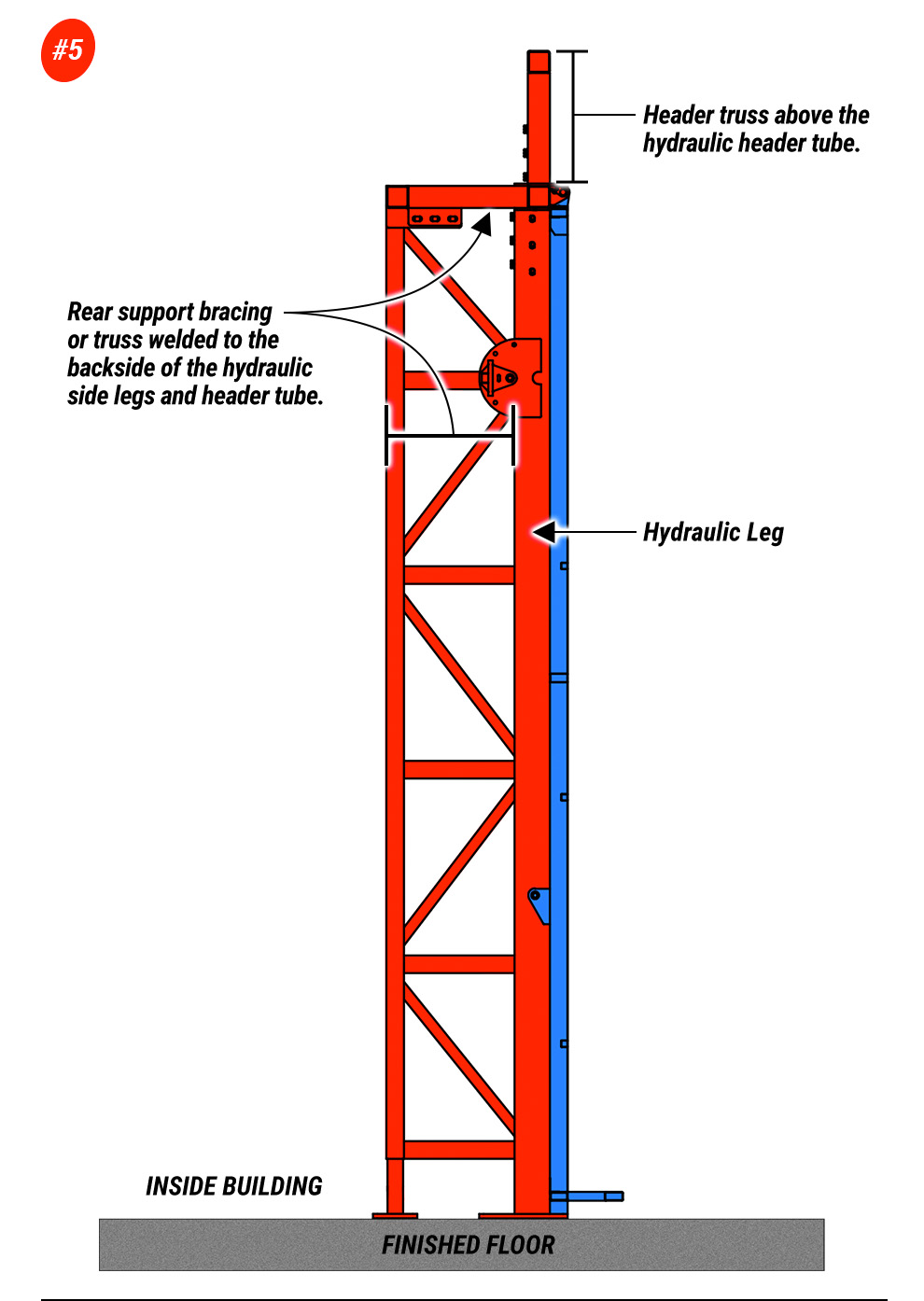

Tri-Pod Legs - We at Schweiss Hydraulic Doors are the only

manufacturer of the Triple-Leg Stand-Alone Hangar Door.

This innovative hydraulic door is the only one of its kind.

WE have taken our existing proven hydraulic door and now have

even made it better! Schweiss is known for perfecting and devel-

oping better designed doors, and we have outdone ourselves

again!

Schweiss Superstructure

Tri-Pod Leg Design transfers the door weights to

the footings that support the

hydraulic door, eliminating the

need for additional side columns

from the building manufacturer.

Lower Building Costs

Schweiss Doors is on the leading edge of hydraulic doors today

Building costs are significantly reduced with our Tripod leg design self-supported hydraulic doorframe. Schweiss is the leader in manufacturing hangar doors for general aviation and commercial jet hangars. Our self-supported hydraulic door is designed with a purpose and a clear objective. The self-supported design will benefit everybody from architects, engineers to building manufacturers, and more importantly will save money for the end-users of the doors.

"To change something, build a new model that

makes the other models obsolete."

While other doors may appear to be the same on the surface, there really is no comparison!

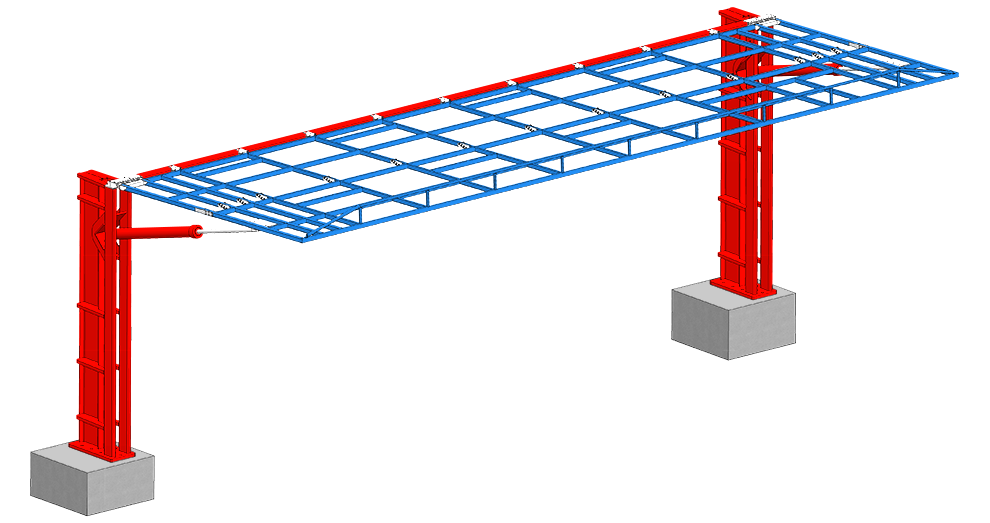

Each door comes prehung with its own frame

• Heavy-duty hinges are pre-welded to the doorframe and horizontal continuous member for ease of installation.

• They are pre-assembled, pre-welded and delivered pre-hung within a pre-squared frame for ease of installation. Each door is fully assembled from the factory, saving you hours of installation time. Compare this to tilt-up doors that are shipped out in a kit form that consists of many bolts, steel members, cables and other components that have to be field-assembled and be field-squared up at the job sight. Assembling a kit door takes more time to install!

• Makes installation easy; framework is standard on all Schweiss hydraulic doors - just lift the framework and door into place all in one step.

NO WELDING NECESSARY

Schweiss door framework consists of a continuous header that's factory fitted to the tripod cylinder legs. The doorframe is attached to the complete framework at the factory making installation easy. The framework adds extra building support. Schweiss self-contained framework simplifies installation.

Self-Latching

Self-Latching: Holds the door in place in the closed position ... never creeps open. The hydraulic pump has a built-in positive-hold valve that maintains and keeps the door locked in the closed position! Hydraulic cylinders automatically pull the doors in tight against your building and will keep the door in a locked position that provides a tight seal.

Schweiss Doors are Powered Up & Powered Down

Doors operate evenly in either direction secured by the heavy-duty hinges.

Self Supported

Hydraulic Door Design

• Schweiss offers choices unlike others, we use common

sense and an innovative approach to provide the right

hangar door solution for your building. The complete

hangar door system will save you time and money!

• Reduce building costs significantly. Schweiss Doors

come with their own door columns. Schweiss realizes

and understands the impact your door will

have on your building.

• Schweiss doorframes mount on the 'New

Stand-alone "Self Supported" doorframe,

eliminating the need for the building

manufacturer to incorporate a building

truss or building header to support the

bifold door on the structure itself; saving

everyone substantial dollars.

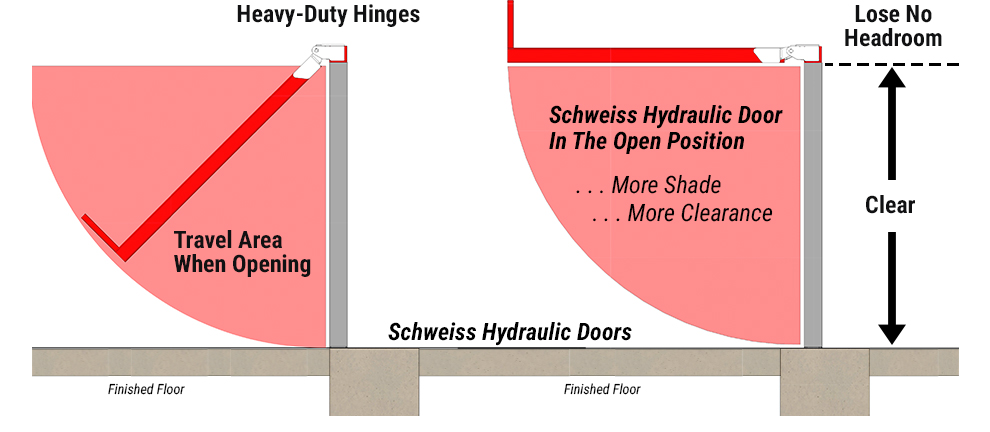

• Lose No Headroom . . . Keeps the overall building

height down, since there is no lost height at the

opening; unlike others where the doorframe rolls back

into the building. Schweiss bifold doors put zero

stress on the framed opening. Smartly engineered!

Tri-Pod Leg DesignFor Hydraulic Doors

TRIPOD DOOR HAS ITS OWN SELF-SUPPORTING SUBFRAME

Schweiss hinges distribute the door loads evenly across the self-supporting subframe greatly reducing stress on the building structure.

• Self supported hangar door is simple

yet seamless in design.

• Door does not put additional stresses

on the building just to hold the door up.

• Only a "Simple framed opening" is needed, helping save the end-user money.

Building Companies Concerns . . .

They are asking, "Can you manufacture a door

that doesn't hang off of the building header?"

• Building prices begin to escalate when

additional engineering is needed on the

buildings structure to handle the loads

of the doors, headers and door supports!

• You can reduce hangar construction

costs and limit headroom

requirements.

• Helps with sustainability and design

efficiency when designing a hangar

building.

• Helps eliminate major structural issues

when designing the building for a door.

• As the metal building provider, why

would we supply an extra steel header

and horizontal supports. They will

add considerable cost of which

not all customers are not willing

to pay for support?

• The more structural steel that can

be eliminated from metal building

cost helps everyone dollarwise!

What Building Companies are Wanting...

Schweiss Delivers

Simple Strong Design . . . Schweiss Strong!

• Provides more of a "rain canopy" when open.

• Provides more of a "shade canopy" when open.

• Power up and power down fully automatic with remote control . . . No short cuts!

• Once Schweiss doors are hung, there's nothing to go out of adjustment.

• Door swings outward, it doesn't impinge on the hangar or shop interior like tilt-up doors.

• Schweiss doors have less moving parts, no rollers to keep from falling out of track, cams or slides.

• Simple, solid design. Less Maintenance!

Installation Made Easy . . . With a Schweiss Door

A customer once shared with us ... "A door is a door ... Right? WRONG! Like many people, I thought all hydraulic doors were pretty much the same, but boy did I learn my lesson. A hydraulic door is only as good as its components. Hinges, cylinders and workmanship, that's what sold me on the new Schweiss hydraulic doors. After helping a neighbor install and operate his Schweiss hydraulic door, I was sold right there, and from then on I knew Schweiss Doors were the right choice for me! The hydraulic door secret was no longer a secret. I proudly told my neighbors how happy I was with my Schweiss hydraulic door."

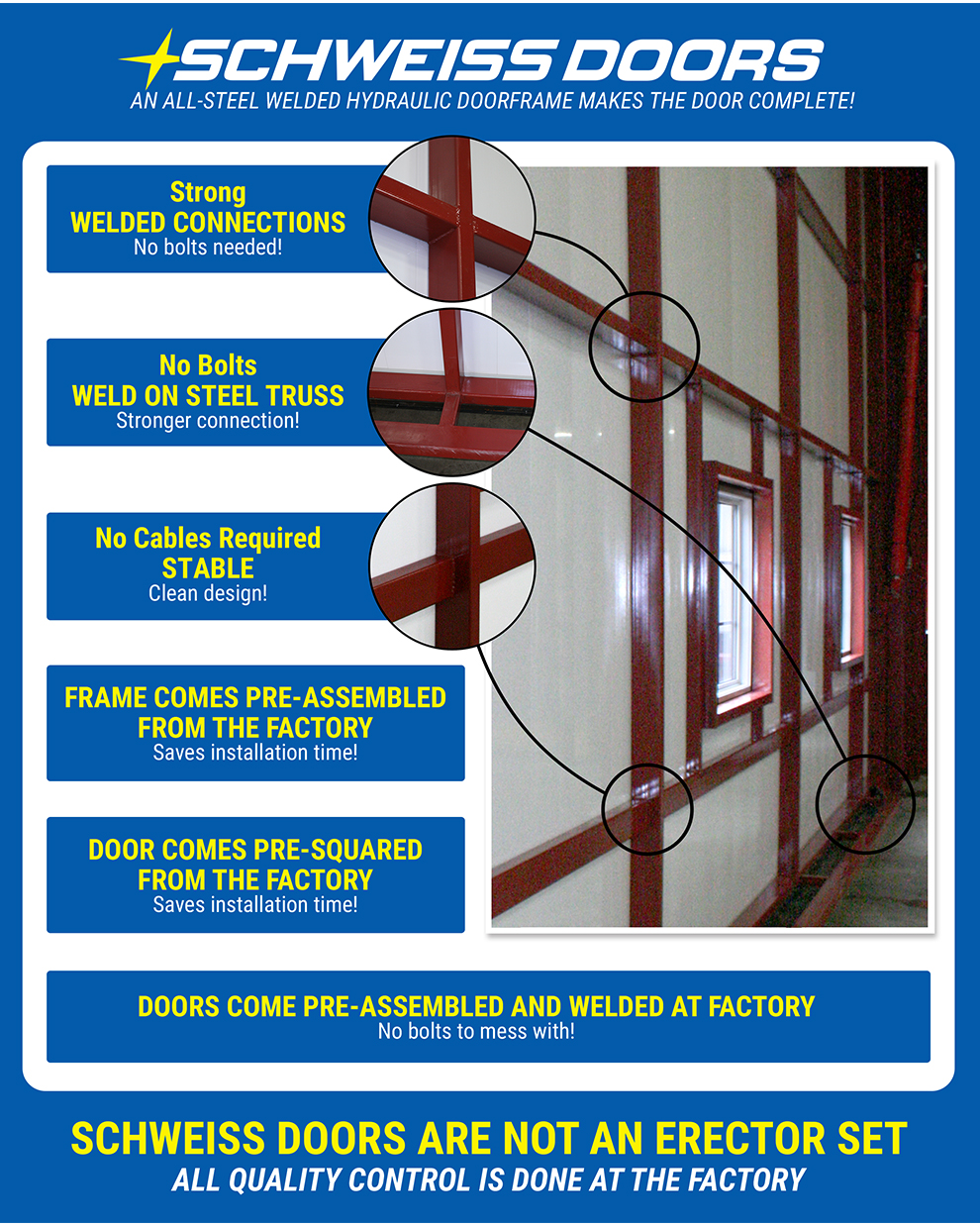

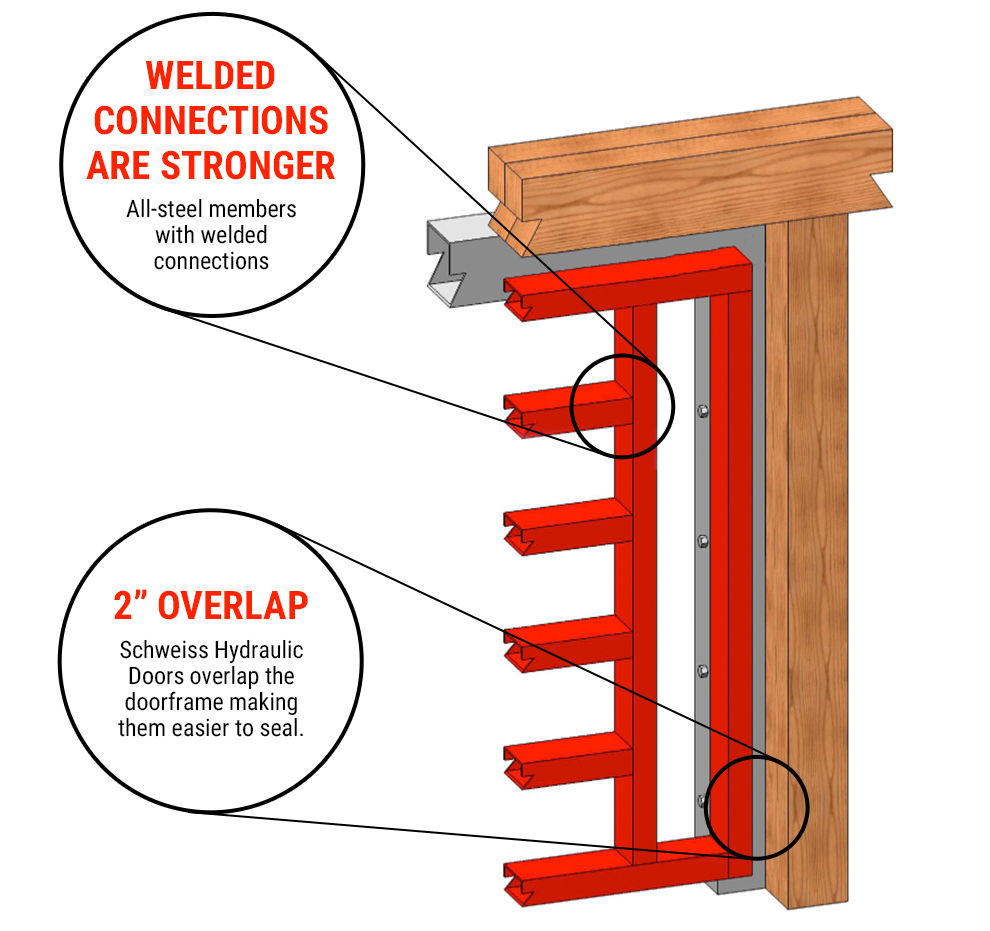

Schweiss Doorframes are Pre-assembled, Pre-welded

A special feature of a custom-built Schweiss hydraulic door is that it comes pre-assembled, pre-welded and delivered pre-hung within its frame for easy installation. Schweiss welded doorframes have no bolts to jiggle loose and doors come welded up square from the factory and ready to install! A fully welded doorframe is stronger when all components are pre-welded in place! Welded doorframes are easier to install and install faster - no adjustments are necessary once the door is in place. This is a real timesaver for the erector that installs the door. The Schweiss Hydraulic Doors can be installed on any building, and best of all they still maintain the headroom requirements ... this is where you can save thousands of dollars by lowering the height of your building and still maintain needed headroom.

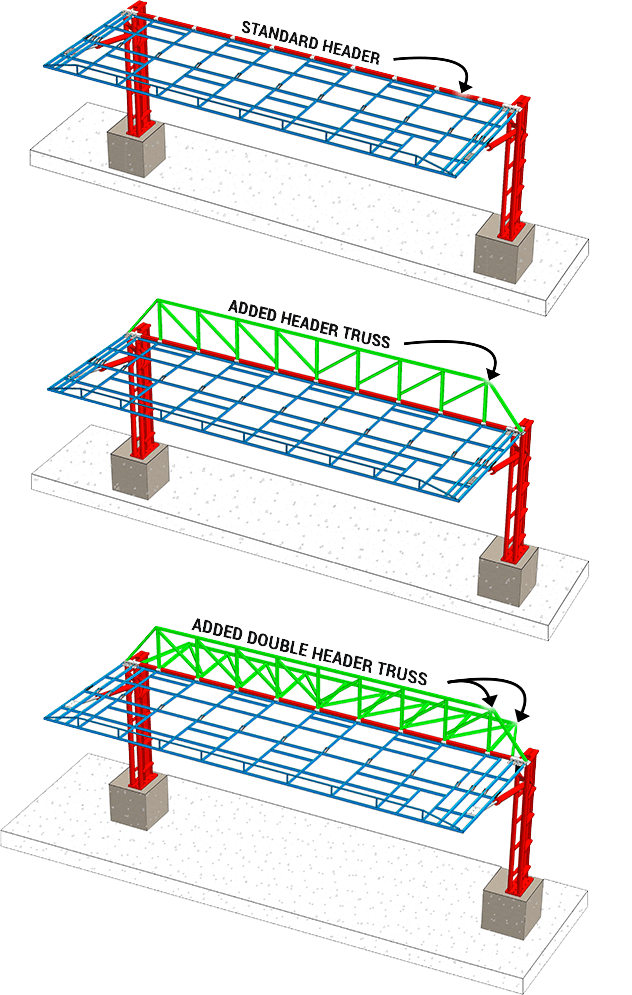

• Schweiss doorframes come pre-assembled with their own header tube and vertical side columns that provide added support for your building structure.

• The doorframe is pre-welded and pre-hung within the subframe for easy installation.

• Pre-located hydraulic cylinder brackets and hinges make door installation easy.

• The doorframe provides additional strength to your building.

• All that's needed is to lift the framework and door all into place in one step.

The buyer/builder gains tremendous flexibility, saving time and money

on installation. Let your next hangar door be a Schweiss!

Big Doors . . .

Buy Schweiss

Schweiss Door Advantages

• It's a significant “rain/shade canopy” when open.

• Once hung, nothing will go out of adjustment.

• Nothing protrudes back into the building.

• No rollers to pop out of the tracks.

• Door is powered up and powered down.

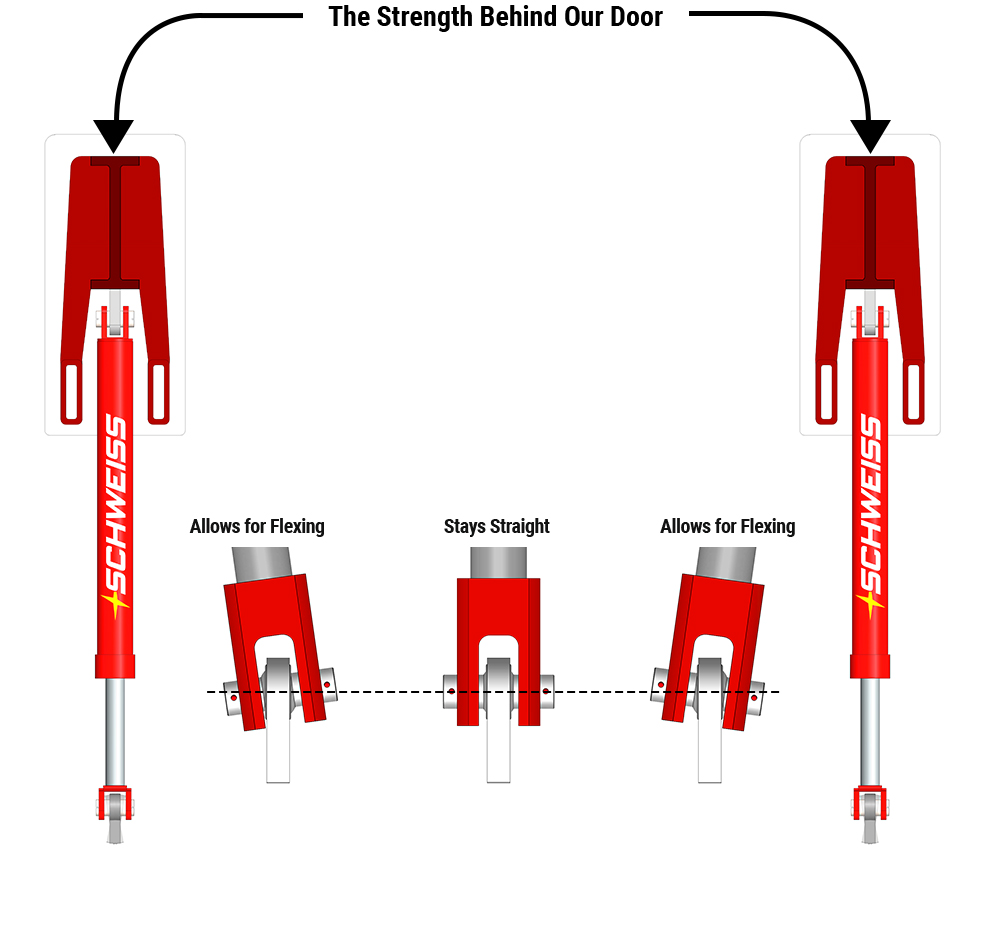

Stand-Alone Tri-Pod Leg Design and Cylinders

Reduce Stress and Wear On The Cylinders, Cylinder Pins and Clevises During Operation

Hydraulic doors are large in size; the doorframe flexes during operation. The hydraulic cylinders on each side of the doorway are supported by the TriPod leg design to support the cylinders evenly.

• Tri-pod leg carries all the weight and forces of the doorframe and

cylinders to the foundation.

• Cylinder forces are supported equally on both the sides and back of

the tri-pod leg. All the loads are transferred into the foundation.

Spherical Bearings

DOORS ARE ALWAYS MOVING AND FLEXING

Hydraulic doors are large in size and just like an airplane wing, the doorframe flexes during operation. The hydraulic cylinders on each side of the doorway are connected to the doorframe and the building using spherical bearings. The spherical bearings accommodate the flexibility of the doorframe while at the same time allowing the cylinders to raise and lower the door without binding on the hydraulic cylinder pins and brackets. Spherical bearings on both ends of the cylinder allow the cylinders to stay straight throughout the full range of motion.

"Soon as I saw and understood the spherical bearing design

it was a no brainer. I was immediately SOLD on the

Schweiss Hydraulic Door!"

"No one else in the industry offers Spherical Bearings"

Only available on Schweiss Doors. . .

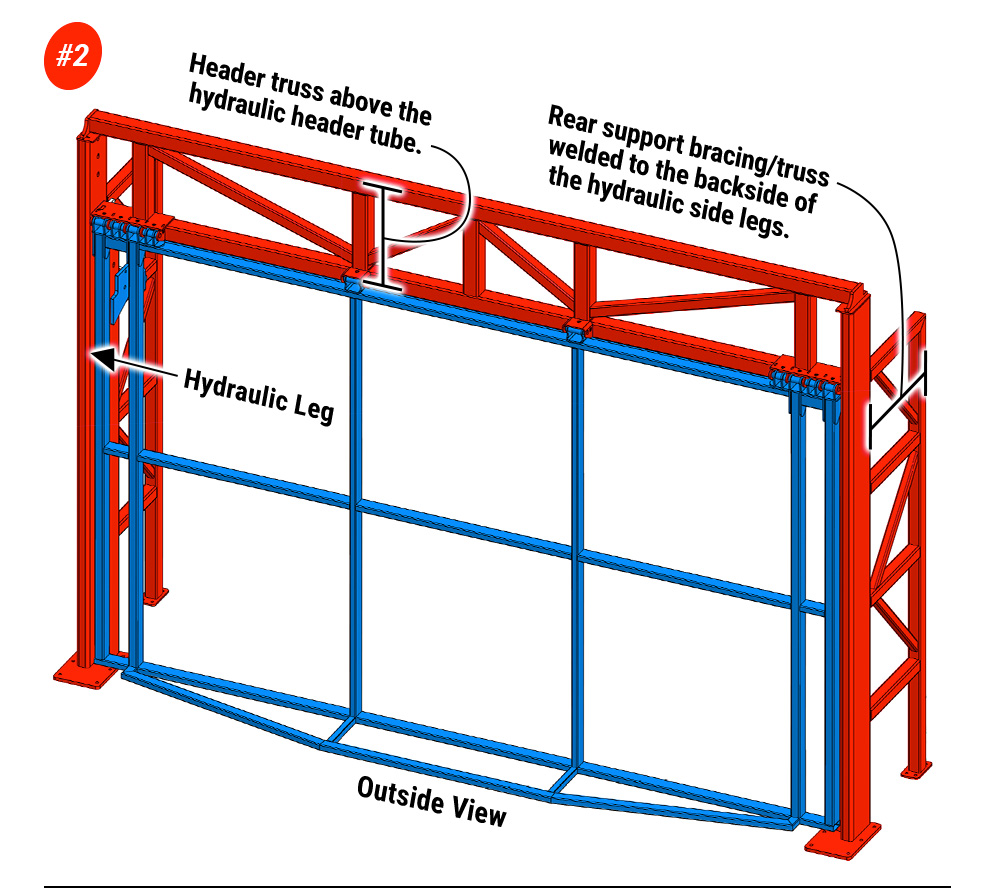

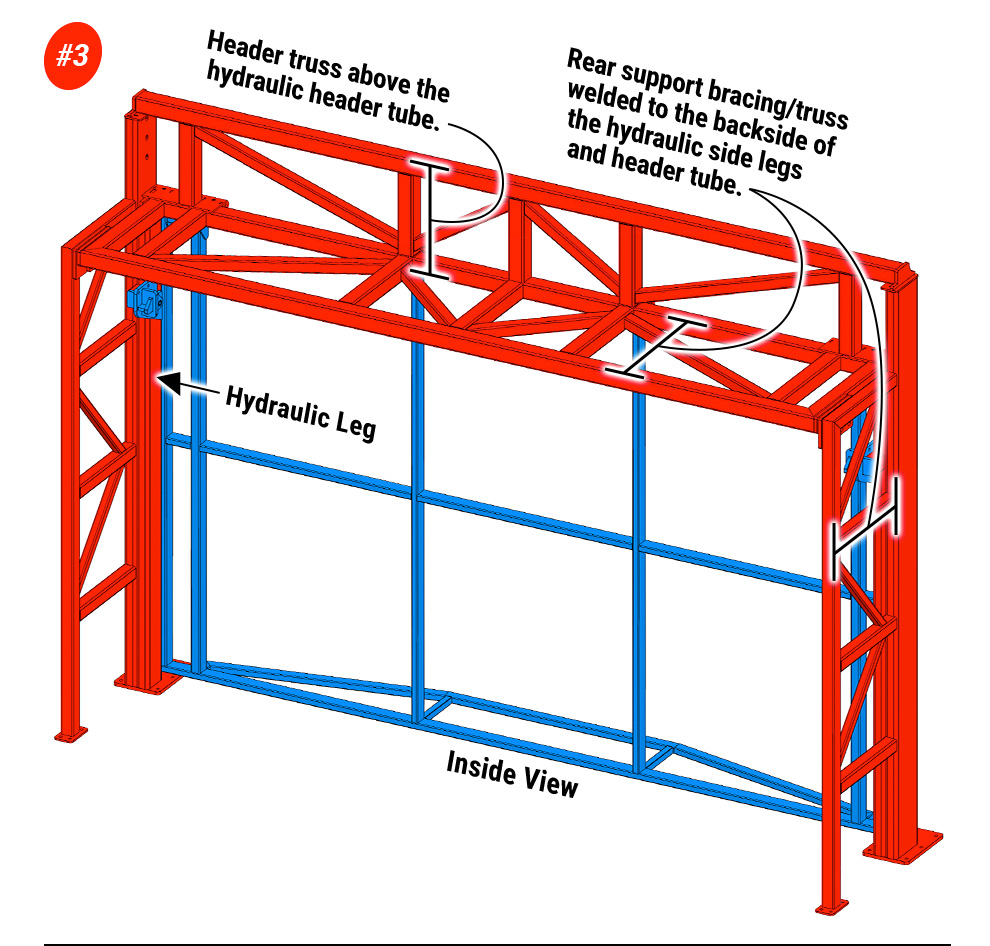

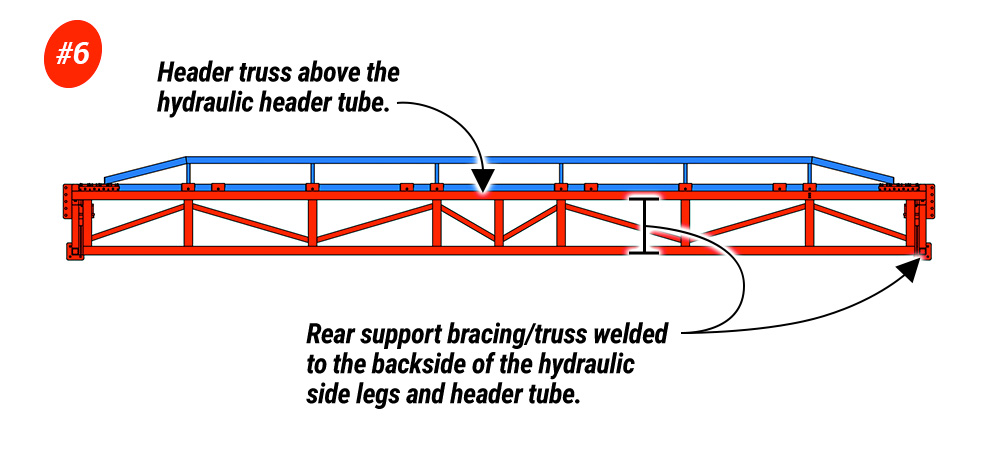

Support Bracing

For Free Standing Header

Here's Why "You Want Hinges!"

THE IMPORTANCE OF . . . HINGES ON A DOORFRAME

The Schweiss hinge has a Robust design over tilt-up hydraulic doors that have no hinges!

Schweiss Hydraulic Doors are designed with heavy-duty hinges that help carry the entire weight of the door when opening and closing! The advantage of heavy-duty hinges on a moving doorframe is that they distribute the weight of the doorframe evenly across the subframe header to give the door stability in all positions! It's all about surface area. Schweiss hinges help spread the forces over a broader portion of the doorframe and header lowering the stresses that are transferred to the hydraulic cylinders and components of the door!

• Schweiss hinges give the door stability in all positions

• Schweiss . . . safety / stability / performance . . . no matter what size door.

Yes, when your door has no hinges you sacrifice the stability of the doorframe

making your door significantly harder to seal.

With that being said, common sense will tell you how important

it is to have "the strength and functionality" of hinges

connected to the doorframe!

HINGES ARE THE SMARTER WAY TO GO !

Schweiss Design . . . Over the Years

Leading the Hydraulic Door Industry

Schweiss has gained a lot of experience over the years.

It's always been interesting to see the different schemes

manufacturers come up with to open hangar doors.

The mechanical ingenuity on display is fascinating!

We have taken our existing proven hydraulic door

and now have made it even better!

Schweiss is known for perfecting and

developing better designed and

engineered doors, and we have

outdone ourselves again!

What Door Customers are Saying...

• "You guys got it figured out!"

• "Schweiss has a terrific door."

• "Nothing on the market comes close."

• "Nothing compares to the Schweiss design!"

• "Schweiss doors have no need for adjustments."

• "Keeps the overall building height down"

• "No lost height at the opening; doors open out!"

• "The grease zerks on their hinges are a home run."

Schweiss Doors

Remote CONTROL Operated Door

The Hydraulic Solution . . . Simple Concept and Seamless Design . . . Mike Schweiss, President of Schweiss Doors, says hydraulics are a powerful, clean, simple, and trouble-free method of operating the doors, and they operate smoothly and quietly. He says the company uses cylinders with larger rod diameters than required for added strength and safety - with rod diameters from 1½ inch to 4 inch, depending on door height, size, and weight. He also notes that the cylinders are beefed-up and strengthened at critical points to avoid putting stress on the cylinders or cylinder pins.

Hydraulic Safety . . . Because of their size and weight, large hydraulic doors require safety features to prevent damage or injury from uncontrolled closing due to a power outage or failure of a hydraulic line. Schweiss incorporates counterbalance valves on all doors, causing the door to lock instantly in any position when not being operated, even if a hydraulic line should leak or burst. Pumps are driven by continuous-duty motors protected by fuse and overload devices. Low-voltage 24v DC control stations with low-voltage coil connectors provide greater user safety.

Hydraulic Backup Solution . . . This hydraulic power unit (HPU) includes a rechargeable battery to allow operating the door in the event of a facility power failure. The HPU can also be mounted above ground on a wall or in a remote location. Additional features include several alternative methods to operate

the door safely in case of power failure. Each unit comes with a standard

tractor hydraulic connection, which is particularly useful for agricultural or

industrial applications. A built-in manual override allows an operator to

lower the door during a power outage, and a DC battery backup also is

equipped with a hex head that allows an impact wrench or drill to operate

the door in either direction if necessary.

The Hydraulic System . . . Power Up and Power Down . . .

Schweiss explains that all of the hydraulic oil in the system that

passes through the directional valve gets filtered. There is a small

amount of oil in the cylinder and the hard lines that never gets

back into the tank to mix with the oil that gets filtered. The pump

includes a filter-clogging indicator that shows when to change

the filter element, this also reduces any chance of an oil mess.

The system's 3,000 psi pressure gauge is standard and shows

the pump pressure used to open the door.

Smart Hydraulic Design . . . Schweiss Doors, Hector, MN,

offers both types of doors and has developed design features

specifically addressed to improve hydraulic door operation over

other designs. At the heart of the companys' system is a hydraulic gear pump

driven by an electric motor ranging in size from 2 hp to 20 hp. The complete HPU is a

compact package that can be mounted anywhere in a building, whether on the floor or a wall

close to the door or further away.

UL-listed electrical components are housed in control boxes, including contactors, transformers, relays, motor timers, rectifiers, and control fuses. The gear pump is 95% efficient and operates quietly at 1,800 rpm. The HPU also incorporates a 3,000-psi pressure gauge, fluid temperature gauges, and a service filter.

Hydraulic Cylinders Handle Heavy Doors . . . Hydraulic cylinders provide the strength and reliability to open and close large, heavy doors on airplane hangars as well as agricultural, commercial, industrial, and residential buildings. They offer smooth, quiet operation, and the one-piece doors create a large, shaded canopy when open.

Hydraulic systems are often the first choice for opening and closing gigantic one-piece doors used on airplane hangars, agricultural buildings, and structures requiring large openings, sometimes exceeding 100 ft. in width and weighing well over 10,000 lbs. These doors need powerful mechanisms to operate smoothly and dependably. Hydraulic power is ideal and adaptable to any size door by increasing cylinder size in proportion to door size and weight.

One-piece doors are preferable in these applications because they swing up and away from the building, and their operation is simple. They do not protrude inside the structure like roll-up doors, which can reduce headroom. Bifold doors, on the other hand, pivot outward as they are raised. This feature presents a different set of advantages and disadvantages. Because bifold doors lift from the bottom, lifting force can be distributed across the width of the door. An electromechanical drive is generally used for these doors, but because

one-piece doors must be pivoted from both sides, hydraulics is generally used.

A big advantage of the one-piece doors is that they provide a large, shaded canopy outside the building when open. With hydraulic power, the doors can be clad with almost any material, including heavy glass and steel siding. Entire storefronts have been incorporated

into door designs.

Remote Control Operated Doors

Let you open/stop/close your hydraulic door from

any vehicle. It automatically unlatches the door so

it can be opened or closed with the handheld

remote.Two handheld remote controls and

antennas are included with each door.

Customers really enjoy this feature! All doors

equipped with remote operators should have a

warning system to alert persons in the immediate

area that the door is about to open or close.

"In today's world, you wouldn't buy a car

without air conditioning, so why would

you buy a door without remotes!"