Bifold Doors

Why Lift Straps

Hydraulic vs. Bifold

Strap Conversion

Stories

Must See Photos

New All Strap Bifold Door

Why One-Piece Hydraulic Doors

Retrofit

Strap Conversion Kits

Farm Stories &

Photos

New Strap Latches

Hydraulic Hinge

On Steroids

Stand-Alone Doors

Schweiss Designer Doors

ARCHITECTS, CONTRACTORS, & ENGINEERS

DEAR VALUED CUSTOMER,

We work with architects, contractors, and building suppliers to make sure the door you order will fit your clear opening and building. We will answer your questions and assist you with shop drawings to make sure that your "Automatic Bifold" door will fit your new or existing building. Available are the door weights, loadings, hinge locations, specs, and fine details.

IMPORTANT MESSAGES:

The customer, contractor/owner, and the building manufacturer are responsible to ensure that the building's structural design is capable of handling all the imposed loads that the bifold door exerts on your door header, endwall, and building. When your bifold door is in a full open position, the bifold door tends to pull away from the building at the hinge line exerting considerable horizontal loads on the building structure in the open position. Your building header design must meet standard deflection and strength criteria, both in vertical and horizontal directions to support the bifold door in all positions.

A1, A2, A3 & A4 SPEC SHEETS

Schweiss Bifold Doors will provide you with those loads that are applied to your building and door. We will provide you with our A-1, A-2, A-3, and A-4 Spec sheets for your actual measurements, movements, weights, and hinge locations. If you have any questions about bifold doors or need technical assistance, feel free to call us at (507) 426-8273.

UPGRADE FEATURES

Schweiss strongly recommends that upgrade equipment be used on every door

WARNING: Without the proper upgrade equipment, the door could cause property

damage, personal injury, or death.

THE SCHWEISS HANDBOOK HAS INFORMATION ON:

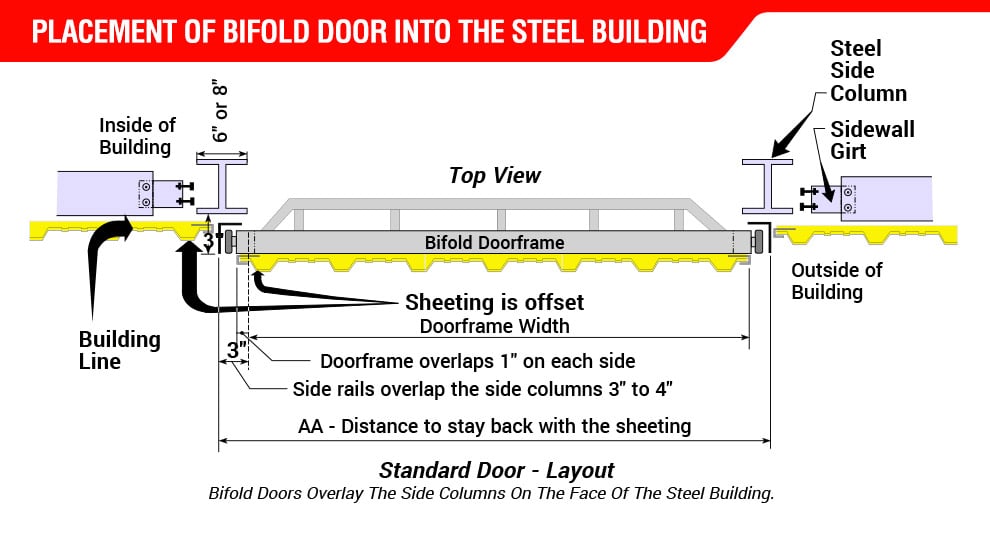

The many different ways to attach a bifold door to your new or existing building structure (wood, steel, Quonset, sidewalls, etc.) Detailed illustrations to help you further understand how to prepare your building for a bifold door, without changing the design of your steel or wood building. Many different applications of an optional Freestanding Header. The Schweiss Handbook should be read by anyone involved in the design, specifications, selection or purchase of an industrial bifold door operator or automated bifold door system.

A. _______ Clear Opening between building Side Columns - Finished Opening.

B. _______ Clear opening from bottom of truss to finished floor - or total clear height opening.

C. _______ Distance from finished floor to the very top of door hinge. B+D=C.

D. _______ Distance from top of clear height to top of single hinge. This distance will vary on different size doors.

The distance above your clear opening will be 12"-24"-30"-36"-48"-Other_______. Circle One.

E. _______ Distance from top of clear height to center of mounting hole for single hinges.

F. _______ Distance from finished floor to beginning of top building sheeting.

H. _______ The distance from the finished floor to the center of the mounting hole for the hinges.

CUSTOMER'S CHOICE OF TRUSS: ___Internal ___External

Very Top

of Hinge

Very Top

of Hinge

Bottom of

Building Sheeting

Bottom of

Building Sheeting

Door Wide Open

Door Wide Open

Bottom of Header /

Rafter / Ceiling Height

Bottom of Header /

Rafter / Ceiling Height

Top

Sheeting

Bottom

Sheeting

1. QUANTITY

1.1 Doors for this project will consist of (___) bifold doors

2. SIZE OF DOOR - Clear Open Width & Height

2.1 Hanger door with door in up position, shall have a minimum clear opening width of (___'___") as shown in the plans and a minimum clear height of (___'___") above finished floor elevation.

3. PLACEMENT of the Bifold Door onto the building - Choose One

3.1 Door shall be mounted on the exterior walls of building.

3.2 Door shall be mounted flush with exterior walls of building.

4. GENERAL / CONTRACTORS REQUIREMENTS: - DESIGN CRITERIA

4.1 The bifold hangar doors shall be designed to the same loading requirements for live loads, dead loads and wind loads on the hangar building.

4.2 The doors shall be engineered to resist all anticipated loads without sagging, bowing or conflicting with its smooth and efficient operation.

4.3 Design for wind load as required by UBC, 1996 BOCA building code. (Example) Wind load (___) mph. Exposure (___)

4.4 The design shall be furnished, approved and sealed by a professional engineer registered in the state where the project is located.

4.5 The building header shall be designed to accommodate horizontal and vertical building deflections to support the bifold door in all positions (with the proper lateral bracing).

4.6 The building's door columns shall be framed of the proper design and size to reinforce the opening (with lateral bracing) and to carry all loads and vibrations imposed thereon.

4.7 The Bifold should have solid footing with sill directly underneath the doorframe and extending outward from the door to provide a base for the door's weather seal. This also prevents flow of water into, or under, the door installation.

4.8 The finished floor of the building should be designed to prevent flow of water under the door installation. Sills shall have a slight slope outward of the bifold door to prevent water flow under the door installation

When building our doors, we do not skimp on material! The doorframes are made out of heavy square tubing with a truss in the center and bottom of the door for extra strength. We have our doors engineered and designed so our metal is in the right places to give you a good, strong, clean door that will stand up and work for you! This super construction lets us offer you the best warranty in the business. We have four different models of bifold doors, each at a very competitive price.

Schweiss Bifold Doors reserves the right to change specifications without any requirement to change or modify past or existing doors. Copyrighted © 2008 Schweiss Bifold Doors. All rights reserved. No part of this publication may be reproduced in any way without permission.