Bifold Doors

Why Lift Straps

Hydraulic vs. Bifold

Strap Conversion

Stories

Must See Photos

New All Strap Bifold Door

Why One-Piece Hydraulic Doors

Retrofit

Strap Conversion Kits

Farm Stories &

Photos

New Strap Latches

Hydraulic Hinge

On Steroids

Stand-Alone Doors

Schweiss Designer Doors

Manufacturing Hydraulic & Bifold Doors

Florida Product Approval

“Cables used to be the standard way to raise and lower a bifold until the invention of the Schweiss lift straps.”

Strap Auto Latches

No Cables

No Clamps

No Pulleys

Available in Florida

By Popular Demand!

Advantages of Lift-straps

| • Quieter | • Easy to install |

| • Safer | • Last longer |

| • Faster | • Easy to maintain |

Lift-Straps are Better

Than Outdated Cables

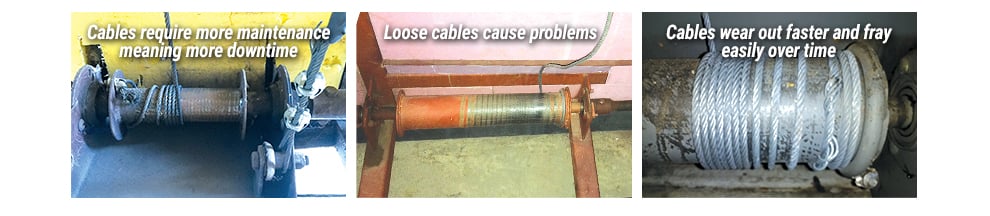

Some manufacturers still continue to try and sell outdated cable lift bifold doors - cable doors that not only require frequent maintenance due to fraying, breaking and overwrapping, but also open much slower, are hard to adjust, are not as safe as straps, and are noisier than lift-strap doors. Straps keep going and going and going.

A Better Way to Lift Doors . . .

Schweiss has revolutionized the bifold door world with it's Lift Strap Invention!

Others try to put the fluff or put the sales pitch back into cable lift doors. Cable doors have been around since the early 1960's! All doors were lifted with the standard cables. Until Schweiss invented this new method of raising and lowering a bifold door! In 1998 Schweiss patented the "New Lift Straps" that forever revolutionized the bifold door world in a positive way! The Lift Strap design has been in use since then. Thousand of satisfied customers are enjoying their Schweiss Doors with the lift straps. As the news travels about the Lift Strap doors Schweiss Doors sales are soaring through out the country!

Cables use to be the standard way to raise and lower a bifold door . . .

New "Market Shaking" Invention

Lift Straps are taking over the Bifold Door Market In Florida!

The most obvious "market shaking" improvements for the Schweiss Bifold Door is the addition of the patented lift-straps along with the new strap autolatch systems, two features not offered by any other door manufacturer. Schweiss lift-straps have revolutionized the door world by opening and closing much more quickly, quietly and effortlessly. Not only are they safer, but they're also easy to install and much longer lasting. It's a win-win for the customer and strap doors are leading the market in the door world. Schweiss Patented Lift-Straps!

Schweiss Doors of Fairfax, Minnesota, USA have been on the market for over 45 years. We manufacture two great styles of doors, the Schweiss Hydraulic Doors and the famous "Lift-Strap" Bifold Doors. What some people don't know is that Schweiss Bifold Doors evolved with the times and many improvements have gone into them, creating a product that Floridians have been asking for!

Once You Try "Lift-Straps" You'll Never Go Back to Cables

Schweiss's excellent success with the New Lift-Straps has revolutionized the door industry. It's a no-brainer. Why bother with cables? It becomes obvious when you understand why the new patented Lift-Straps are the smarter way to raise and lower your bifold door. Smoother, safer, faster and quieter. Like a customer once said, "My strap bifold door is the envy of my fly-in community. I'm happy I bought the Schweiss Door!"

Straps eliminate cable problems that bifold customers have lived with for years.

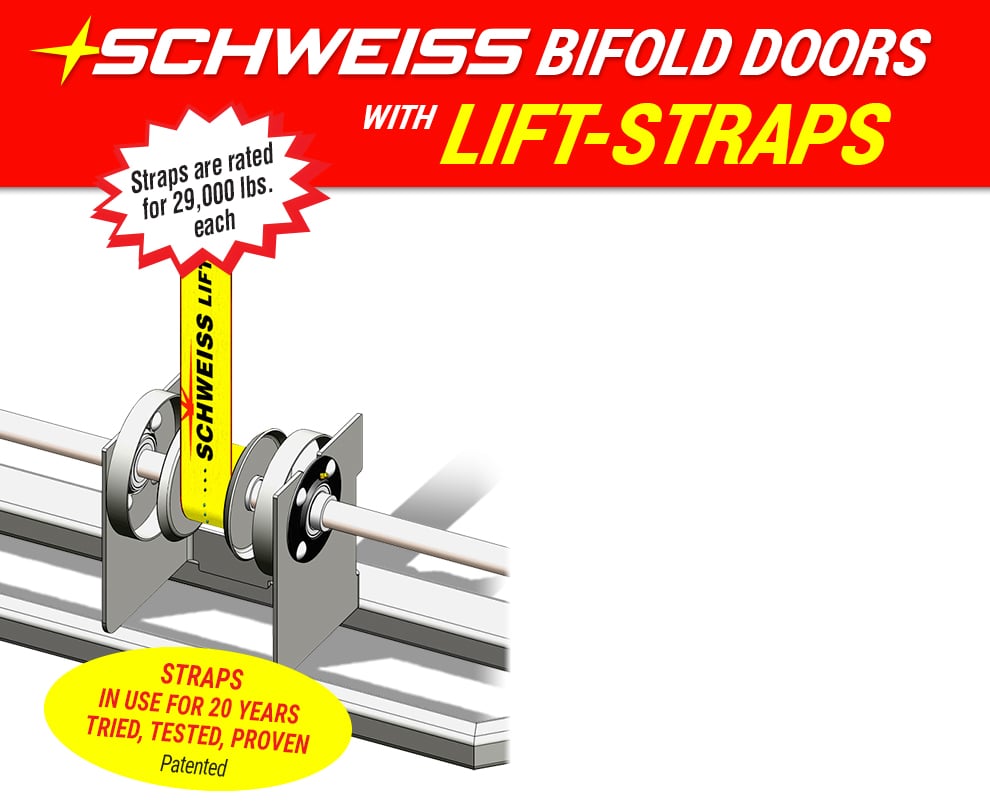

Tested and Proven... Lift-Straps

For years, bifold doors have been lifted and lowered by the conventional means of steel cables. Schweiss Doors have been using the popular, long-lasting lift-straps for over 27 years. Now 99 percent of our customers are demanding polyester lift straps for this function. Why? Because lift straps offer more lifting ability, won't fray or overwrap! The strength-to-weight ratio on straps is extremely high. The 3-inch straps are rated at 29,000 lbs, where 1/4" cables are rated at only 7,200 lbs. In addition, the safety factor on straps is well over the standard 5:1 ratio.

Here's what customers are saying about their strap bifold doors

| "The lift-straps work good and lift faster - the cables were so slow, the door works great now." |

"I can't say enough about your lift-straps, I wish I'd done it originally." |

"Cables were breaking on our big hangar door and we knew the lift straps were a better system." |

| "I'm thrilled with lift-straps, they're great, and they open my door 10 times faster than before. I absolutely will recommended them to everyone." |

"A lot of guys are coming to look at our door. I'm sure you'll be selling more Lift Straps, we like 'em!" |

"Our door with lift-straps now works really well - a 100 times better than before. Our cables broke on us and that was a mess." |

| "The decision to get lift-straps on my bifold door was more of a safety issue for me." |

"Straps are the only way to fly. No noise, no creeps, no crunches. Cables wear out." |

"We converted to lift-straps for reliability and aesthetics." |

Everyone wants the door with Lift- Straps

"I am in the process of bidding a hangar and need a bifold door quote, 32' clear length. The bid package states that only lift-straps, not cables are approved. Please send specs and cost. Thank you."

Cables are the Old Standard!

"You never buy a car without air conditioning . . .

Why would you buy a door without Lift Straps? . . . You wouldn't!"

Strap Doors Sell themselves

STRAPS vs. CABLES

Straps vs. Cables

• Straps never get tangled unlike cables . . .

• Straps wrap on top of themselves and never tangle up.

• Straps are the smart way safer than cables.

• Straps out performs any cable door in life and strength.

• Straps are stronger and safer.

• Straps are easier to handle and install.

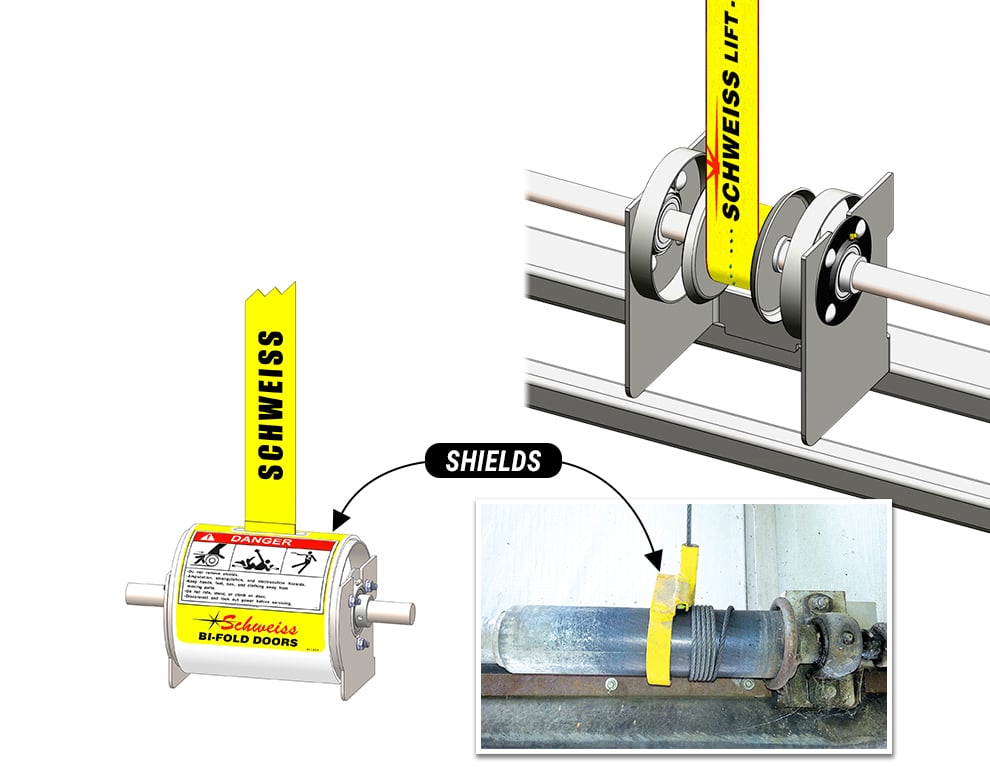

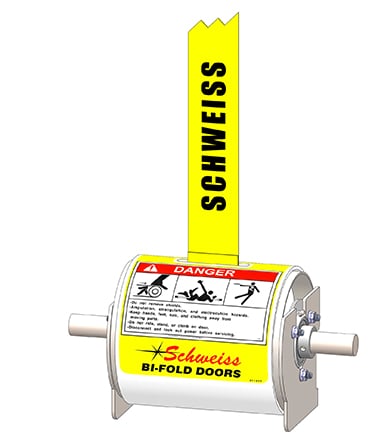

Lift-Strap Shields are safer

Straps are totally enclosed.

Rotating drum totally enclosed.

Protects you in all positions.

Cable wraps are exposed . . . Not Shielded

Rotating cable drum is exposed . . . Not Shielded

LIFT-STRAPS CAN BE INSTALLED

ON ANY CABLE DOOR

HAVE THIS:

Strong, quiet and dependable

Schweiss lift-strap doors

NOT THIS:

Slow, noisy and

outdated cable doors

Strap Conversion Kits:

Yes, "Strap Conversion Kits" are available. "The word is out!"

Schweiss will do strap conversions on other brand bifold doors, no matter the make or model. Schweiss has received thousands of calls from existing outdated cable bifold door owners wanting to retrofit their outdated cable door system to the "Schweiss Patented Liftstraps"

Best Testimonial Ever

Schweiss has recieved thousands of calls from owners of existing out dated cable bifold doors wanting to retrofit their outdated cable lift system with the Schweiss "Lift-Straps system."

Some manufacturers still try to sell

Cable Doors

Cables - wraped on a small sized lift drum the useful life span of cables are shortened . . . wear out sooner

Cables - when they start to wear out, the internal stands of the cable begin to fail . . . wear out sooner

With cables, you have to deal with the cable clamps - proper tension on the cables

is critical! Cable doors require more maintenance, have a shorter working life, are

slower, wear out sooner and aren't as safe as straps.

| • Cables are slower! | • Cables require more maintenance! |

| • Cables fray! | • Cables are hard to adjust! |

| • Cables break! | • Cables are noisier! |

| • Cables overwrap! | • Cables require cable clamps! |

Facts about Cables

Cables must track side by side or wrap up along side of each wrap . . . when the cables has any slack in it . . . cables start to mess up and get tangled up.

Cables that become slack will overlap . . .

Now you have a mess of tangled cables

By Adding Numerous Lift Points

The only reason a cable door manufacturer would add more cable lifts to a door is because cables are not as strong as lift-straps. More cable lifts means more maintenance, more expense - why fight the outdated cable concept and costs involved! Using more cables may translate to less load per cable, but who wants more cables if cables are already known to cause headaches and loss of time to replace (they are known to break when you least want them to, for example during harvest, in 20-below weather, etc.)

More cables are needed to gain

a better safety factor . . .

More cables = More cost, More headaches,

More maintenance . . . More trouble

By Offseting the cables as they

wrap up on the lift drum

Offsetting the cables during lifting of a bifold is a great concept, until your cables don't have the proper tension. Then you end up with messed up cables again! Unlike straps that wrap on top of each other. Tension is never an issue with lift-straps nor do they get messed up. Straps are a perfect design... trouble free. Using lift-straps saves you from all those headaches.

Everyone's Fed up with cable doors

Cables are the old way. Everyone knows cables have a tendency to fray over time. Frayed cables can break and doors can come crashing down on aircraft, machinery or even people. Cables require more servicing, are hard to work with and difficult to replace. Replacing cables with more cables is a timely and costly expense and can be a real safety issue if the cables are not kept in good conditions

Straps are a better design that solves outdated cable door issues

Schweiss Lifts straps have proved to be a far superior method of lifting any bifold door. Lift straps wrap on top of themselves by design. No worry with overlapping issues or with cables rubbing against each other. Furthermore, everyone knows that cables are not even close to being as quiet as liftstraps. Can you imagine the noise that 10 or even 50 cable must make?

Did you know . . .Schweiss can retrofit your existing cable door?

Strap Conversion

#1.

Schweiss has figured out and designed a way to modify any bifold that's ever been manufactured. Retrofitting an existing cable door over to the Schweiss design "Lift Straps" is possible on other brand bifold doors, no matter the make or model.

#2.

Schweiss has brought relief to customers with the old vintage cable bifold doors. Finally the customers with cables can be at ease. They're able to do away with the antiquated cable lift design and retrofit any style or brand bifold door over to the latest and greatest Schweiss "Lift Straps."

#3.

The strap advantage is huge. Straps are longer lasting, never rust, never tangle, are flexible, open a door faster and are 100 percent quieter than steel-on-steel cables. With lift straps, door owners get a "soft start" and "soft stop", adding to the life of the bifold door. Schweiss stands behind the "New Lift Straps" by carrying a 10-year warranty and straps outlast cables well over three times.

Cable Bifold Door Owners Are Asking

• "It's not your bifold door. Can I buy just the 'Lift Straps' and convert my door over to the straps?"

• "Can you convert my cable door over to straps?"

• "My doorframe is good but I'm tired of changing out cable every couple of months!"

• "Will your straps work on my door, it's another brand?"

• "I was at the neighbors hangar and saw how smooth and fast a Schweiss Door operates. Can you help me?"

• "My door is not the old but I hate my outdated cables. Can you convert my door to straps and autolatches?"

• "I see your strap doors are much faster than my outdated cable door. What's it gonna cost me?"

• "I was trying to save money by going with cables. Boy, what a mistake!"

What Strap Conversion

Customers are saying:

• "Why would anyone even consider outdated, slow cable doors today. I wish straps were available when I purchased mine!"

• "I still like bifold doors. Now with the straps and auto-latches they're even better!"

• "Nobody will sell me another cable door!"

• "The Strap conversion made my door better than new!"

• "What a nice Improvement to an older door!"

• "Straps and auto latches, what a great improvement!"

• "You guys are good, thanks for the neat inventions!"

• "Should have done the strap conversion years ago!"

• "If anyone asks. send 'em my way and I'll be your salesman. I love my door now!"

Best Testimonial Ever

Schweiss has recieved thousands of calls from owners of existing out dated cable bifold doors

wanting to retrofit their outdated cable lift system with the Schweiss "Lift-Straps system"

Vero Beach, Florida airport packed up

its hangar cable troubles with 14 bifold

liftstrap door conversions

There's a marching song made popular during World War I whose lyrics begin with . . . "Pack up your troubles in your old kit-bag . . . And smile, smile, smile!"

“The City of Vero Beach was really, really happy with the whole 14 hangar door setup and how it went down. Schweiss has a better designed and cleaner operating system. By the third hangar we had a system set up to where we had all the structural components ready and our own welders and electricians ready to hook things up. We worked through all the small issues of adapting Schweiss equipment to an existing hangar door. We had great support from Jeremy at Schweiss Doors. By the time we were on our sixth hangar door we were a moving machine where everybody knew what they had to do. I would definitely recommend Schweiss doors and strap conversions to others.”

- Jim Lavold, Contractor

James S. Lavold, Inc.

Jupiter, Florida

In retrospect, that's sort of what Jim Lavold, co-owner of James S. Lavold, Inc. did when his family -owned general contracting company completed 14 Schweiss Door liftstrap conversions on lease and rental Box and T-Hangars for the Florida city-owned Vero Beach Regional Airport. Now the city and aircraft owners are smiling, smiling, smiling because these 20-year-old cable-lift doors ago no longer pose a safety hazard and lift faster and much more efficiently.

"As an approved contractor for the FAA we do a lot of airport work and renovations. We also work on local government-owned and private hangars, hurricane repairs and things like that. We travel all over the country and work in all states. We did a project for the FAA renovating control towers in Hilo, Hawaii, St. Thomas, St. Croix and Puerto Rico," said Lavold.

Lavold's general construction business is located in Jupiter, Florida, about an hour's drive south of the southeastern coast city of Vero Beach. It's a place where you can experience beautiful beaches, luxury amenities and an easygoing lifestyle.

"We picked up on this Vero Beach project because it was something we specialize in anyway. There were other structural parts to this hangar project other than the strap conversions," said Lovold. "Vero Beach wanted the Schweiss conversion kits for their existing 50 ft. wide x 20 ft. high steel doors originally manufactured by, antiquated to say the least, Wilson Doors who are no longer in business. They had trouble with cables busting. On one occasion a cable snapped, and a door came down and hit one of the planes.

Lavold said the pilots are a lot more at ease with the strap systems modernized with automatic latch systems. He got to know a lot of the tenants and they were really excited about this city project that actually got through funding and worked out.

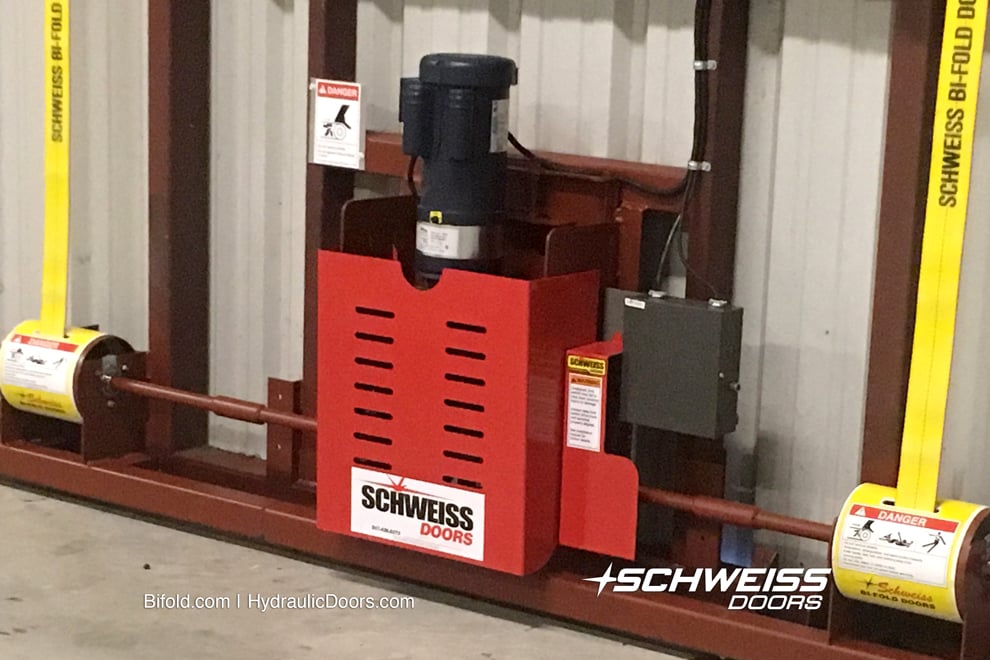

The City of Vero Beach approved the liftstrap conversion as part of its Airport Master Plan that projected a vibrant airport to meet the needs of the entire region. The electrical control boxes for the liftstrap doors were mounted just to the right of the bifold walk doors.

"The City of Vero Beach was really, really happy with the whole 14 hangar door setup and how it went down. Now the airport operations people who have taken over maintenance on these doors have said, 'There's nothing left for us to do - everything works great.' We had an independent on-site engineering inspection team that wrote me a nice letter commending us on how we took care of everything," said Lavold.

Once the Lavold team got working on the installation of the liftstrap conversion they breezed right through it.

"Schweiss has a better designed and cleaner operating system. At first, we had a learning curve on how to get through installing it. By the third hangar we had a system set up to where we had all the structural components ready and our own welders and electricians ready to hook things up," noted Lavold. "We worked through all the small issues of adapting Schweiss equipment to an existing hangar door. We had great support from Jeremy at Schweiss Doors. By the time we were on our sixth hangar door we were a moving machine where everybody knew what they had to do.

"I would definitely recommend Schweiss doors and strap conversions to others. We are actively seeking out new projects starting in Florida, but we will go anywhere. The City of Vero Beach still has two box hangars with bifolds on them that they want to switch over when they get approved for funding," added Lavold.

James S. Lavold, Inc. is located at 952 Jupiter Park Lane, Suite 4, Jupiter, Florida. Phone (561) 747-5050. Email: jimlavold@msn.com

Yacht & Boat Storage Door

Schweiss Has Designated Loads Just For Florida!

Contact Us

Call Us At

800-746-8273