Six Styles to Choose From

1st - Strap BiFold Doors

Quality - Our Top of the Line Door

Best Door Money can Buy

New patented "Lift Strap" System features durable polyester material. The number of straps depends on the size of the door. Adequately sized lifting drums give a 5:1 safety factor.

How Do The Straps Work

The straps wrap around the lift drums as the door opens. As the drum's circumference increases, the door opens faster. It's ideal! The door opens slowly, then picks up speed.

Why Consider The "New Lift Straps"

Already 90% of our doors get ordered with "THE NEW LIFT STRAPS SYSTEM" so it is obvious customers are catching on fast and for all the right reasons... It's a clean, strong design which makes it Faster, Safer, Simpler, Easier, Quieter, Smoother and most important it's been "Proven." Be sure to read our latest literature on the "New Lift Straps"

Framework

3" x 3" Square Tubing or 2" x 2" Square Tubing

Power Unit

Top or Bottom Drive Available - Electric Operated

The gear motor is equipped with an electric brake, guaranteed to stop and hold door in any position of door travel. Electric operator is pre-wired and fully assembled. The motor and gear box and all necessary hardware are included. All drive bearings come standard with grease fittings. Our heavy duty components ensure you many years of use.

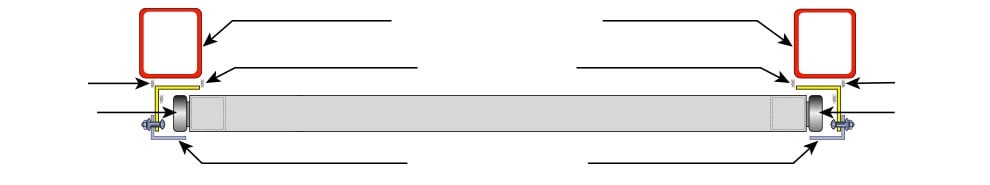

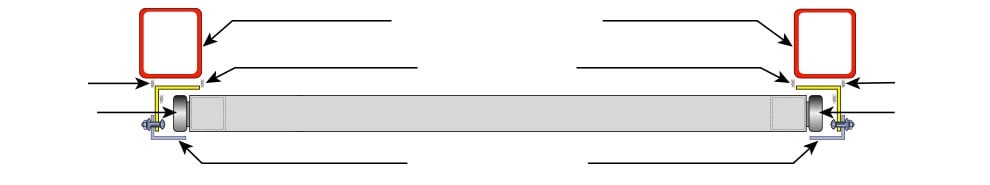

Lifting Method

The solid steel driveshaft has 3" lift drums mounted by each lift point on the bottom cord of door and runs continuously along entire door width providing an even lift at all times. Each lift point has greasable bearing mounts. We use 2, 4, 6, etc... lift points on each door depending on the size of your door. The 3" lift drums are shielded to avoid any potential hazards to people.

Bottom Rollers

Mask Bearings - Extra Heavy Duty 3" Roller Bearing Wheels

2nd - "One Piece" Hydraulic Door

Framework

2" x 4" Square Tubing --2" cross tubes

Power Unit

Electric over Hydraulic Power Unit

Self contained Electric / Hydraulic Power Unit comes from the factory fully assembled and ready to operate your door trouble free for years to come.

Each power unit has a oil reservoir, a direct drive motor to the hydraulic pump protected by an oil filter (Standard on all models) complete with gauges.

Each power unit is set up with universal wall or floor mount brackets that are very easy to install. This makes our power unit stand out from other models on the market - The motor is sized to lift your door for many revolutions for years to come.

ALL SCHWEISS POWER UNITS ARE READY TO WORK. THEY EVEN HAVE THEIR OWN TEST CORD FOR EASY INSTALLATION OF YOUR DOOR. CONVENIENCE FOR THE CUSTOMER INSTALLING HIS OWN DOOR.

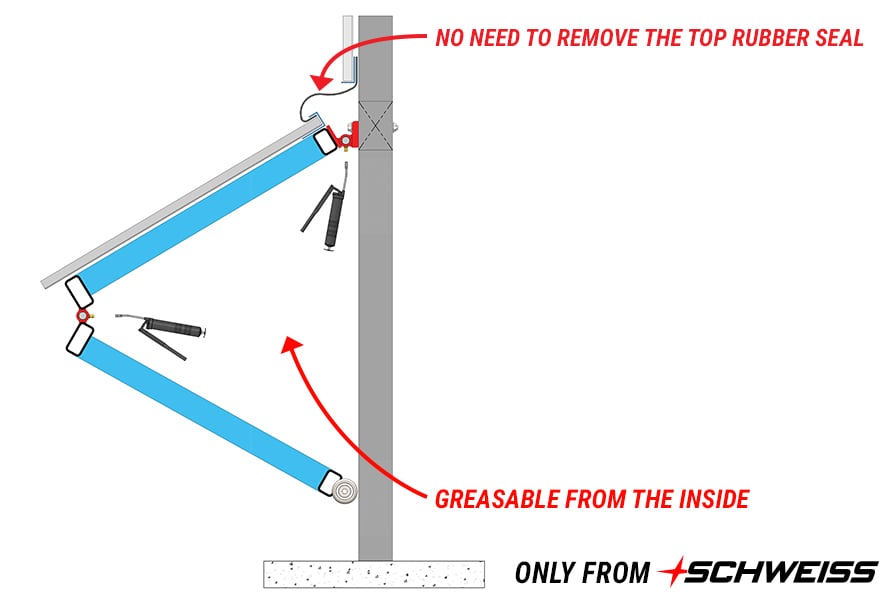

Lifting Method

Hydraulic doors are opened with two Hydraulic cylinders with safety built in. There is one cylinder located on each end of the door. Both hydraulic cylinders are used to raise and lower the door. Schweiss provides extra heavy-duty cylinders that will give you many years of use on your door with trouble free years of operation.

3rd - Cable BiFold Doors

Use heavy 1/4" aircraft galvanized steel type lifting cables. The number of lift cables depends on the size of door. All cables are sized & the lifting drums are insufficient in amount to give 5:1 safety factor.

Framework

3"x3" Square Tubing or 2"x2" Square Tubing

Power Unit

Bottom Drive - Electric Operated

The gear motor is equipped with an electric brake, guaranteed to stop and hold door in any position of door travel. Electric operator is pre-wired and fully assembled. The motor and gear box and all necessary hardware are included. All drive bearings come standard with grease fittings. Our heavy duty components ensure you many years of use.

Lifting Method

The solid steel driveshaft has 3" lift drums mounted by each lift point on the bottom cord of door and runs continuously along entire door width providing an even lift at all times. Each lift point has greasable bearing mounts. We use 2, 4, 6, etc... lift points on each door depending on the size of your door. The 3" lift drums are shielded to avoid any potential hazards to people.

Bottom Rollers

The wheels at the bottom of the door jamb roll up each side column. We use EXTRA heavy-duty bearings that measure 3" to provide a smooth operation.

4th - Designer Doors (Hydraulic & BiFold)

We have the reputation for creating distinctive, custom designer-style doors. With your thoughts, and our door expertise, together we will design the ultimate door for you to exactly match the designer door of your dreams. If you can think it, we can make it. Let your imagination run wild, as we begin with the best, and move higher, exceeding your every expectation. We don't just build our doors for anyone. We build our doors for you!

5th - Hand Operated - BiFold Doors

Used when power is not available (Door must be of great quality)

Framework

1.50" x 1.50" Square Tubing

Power Unit

Manually Operated with a Mechanical Hand Winch - Not Electric

Lifting Method

Cables or Straps operated with a Hand Operated Mechanism

6th - Aluminum Framed Doors

Schweiss offers aluminum framed doors. We manufacture our Aluminum frame doors like no others - built with style and most important strength of the members.We manufacture the door frames out of square and rectangular members to give the nice clean appearance. You add the new lift straps to our Aluminum doors. Now you have the best of both worlds, the popular lift straps and the cleanest looking door in the world.

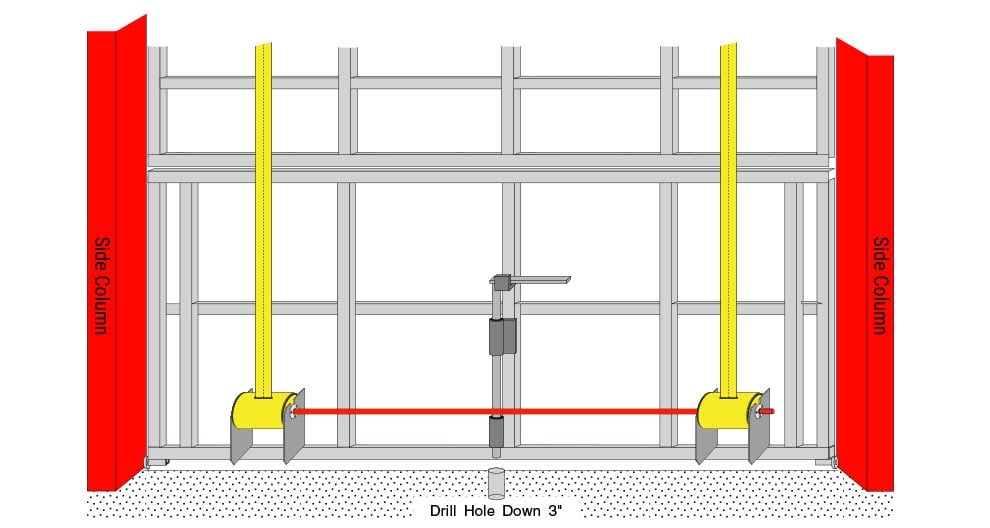

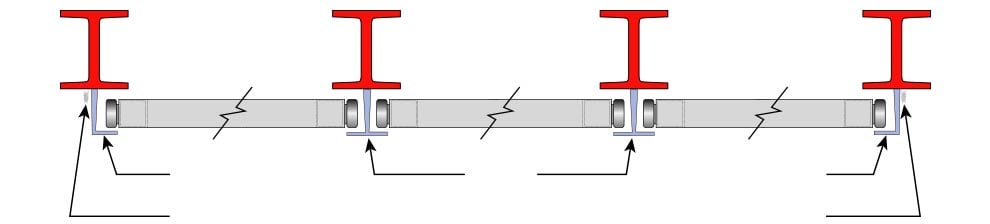

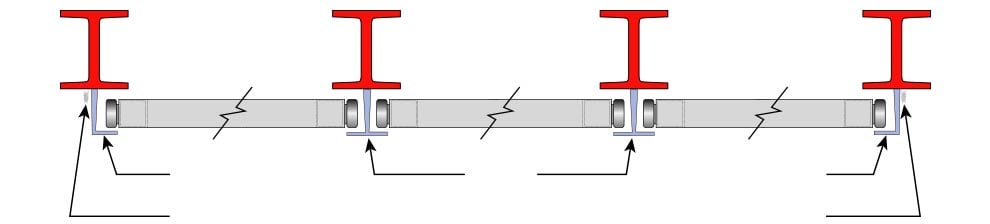

SIDE RAILS, WIND RAILS, COLUMN FOLLOWERS, WIND PINS

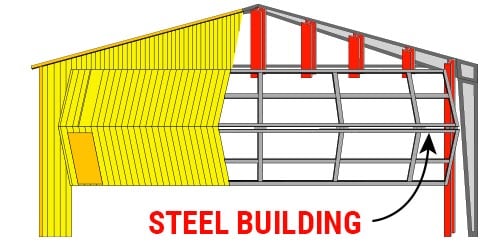

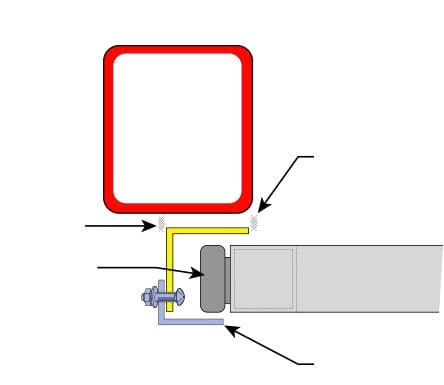

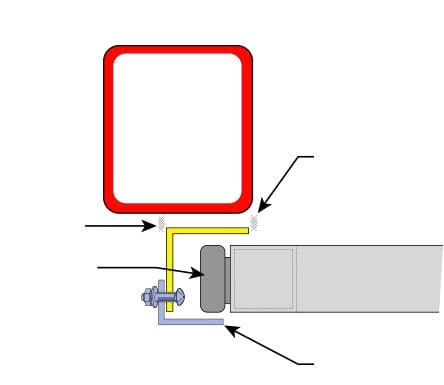

SIDE RAILS USED ON RECTANGULAR COLUMNS

On each side of your door opening the side rails mount to each door jamb. The bottom door rollers roll up on each side rail. The door rolls up on these side rails, providing a safe guide for the door rollers as the door opens and closes. Our side rails are heavy 1/4" thick angle iron for good solid backing.

Tube Steel Column

Side Rail

Weld

Single Roller

Wind Rail

Doorframe

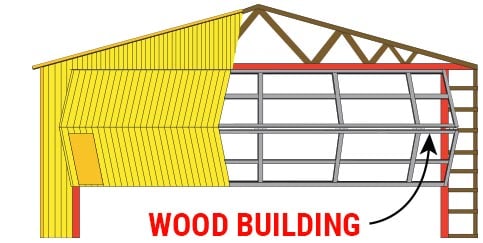

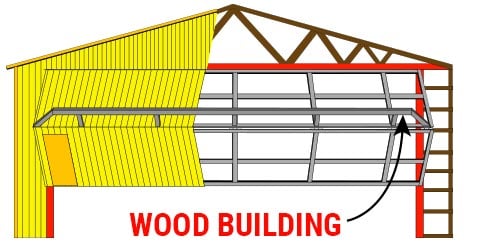

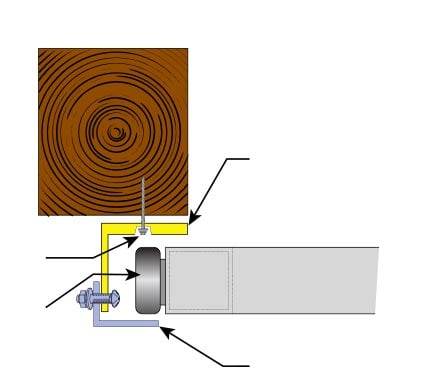

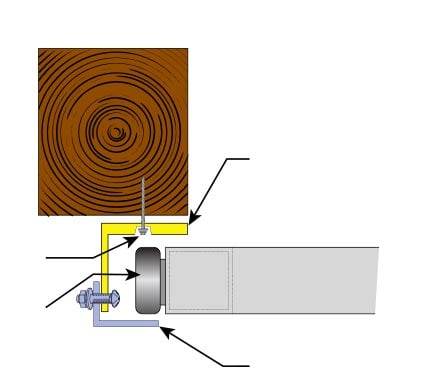

Wood Column

Side Rail

Screw (Flush)

Single Roller

Wind Rail

Doorframe

WIND RAILS USED ON BIFOLD DOORS

Designed to hold the base of the door security against the building when the door is in the closed position.

Our two styles include:

1 - Wind Rails. Included are safety wind rails attached to the bottom of the side rails. Used on solid square columns.

2 - Continuous Wind Rails. Continuous safety wind rails can be attached on the side rails. Run from the bottom all the way to the top of the gear openings. The Wind Rails Hold the bottom roller in place when the door is closed

5/16" bold & nut in 3/4" x 3/8" slot

Doorframe

3 - 1/2"

3 - 1/16"

Wind Rail

Bottom Roller

Side Column

Side View of Wind Rail

Side Column ( e.g. Steel )

Side Rail ( 3" x 3" )

Bifold Door

Weld

Weld

Single Roller

Single Roller

Standard Wind Rails

Weld

Weld

T-Rails

End Wind Rail

End Wind Rail

"T" Wind Rails - Multiple Doors on Steel Building - Side-by-side

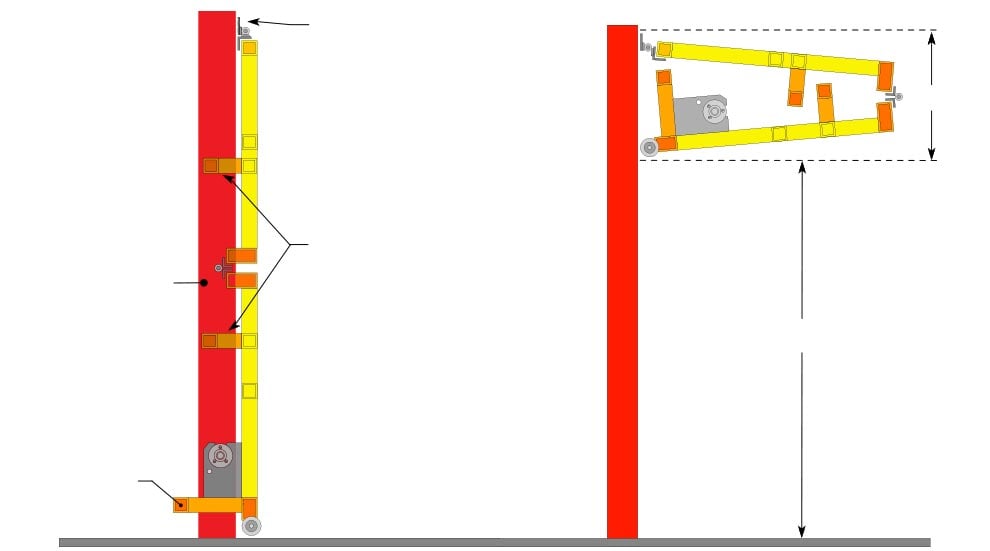

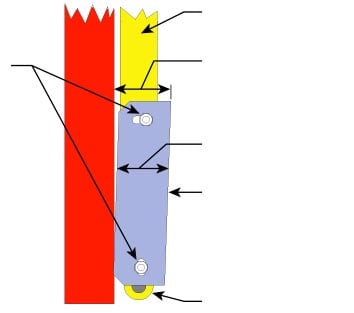

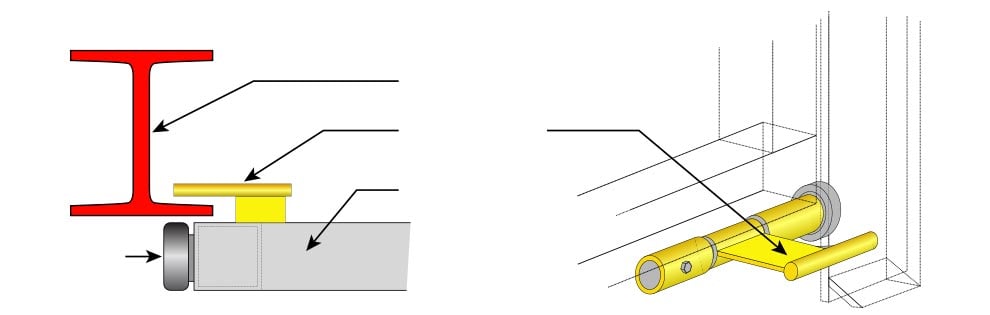

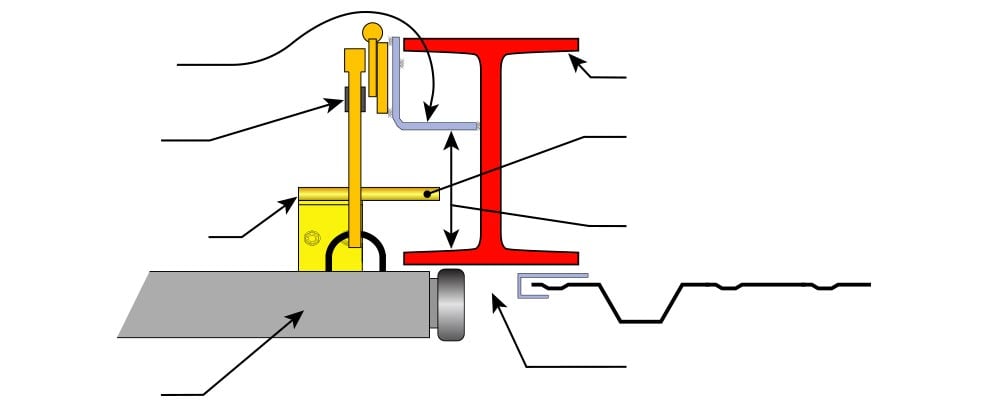

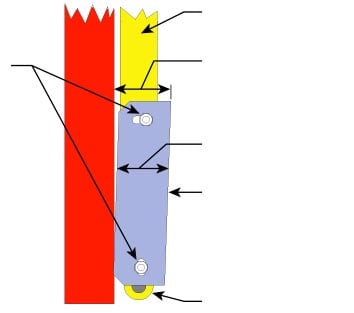

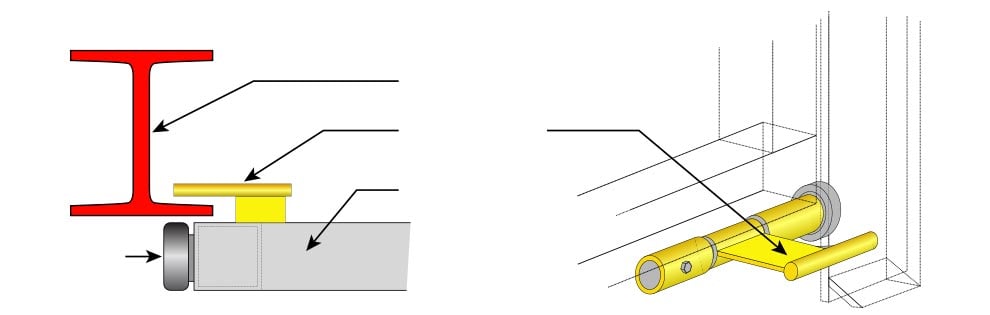

COLUMN FOLLOWERS USED ON I-BEAM COLUMNS

Side Column ( e.g. Steel )

Column Follower

Doorframe

Single Roller

Designed to hold the base of the door securely against the building when the door is in the closed position. I-Beam Columns secure the door in all positions.

Gusset Plate

Side Latch

Column Follower

Doorframe

Steel I-beam side column

Column follower slides up inside I-beam column

Hold back 1 - 1/2" to 2" - Important

Steel I-beam columns may have column followers - (Less the side rails)

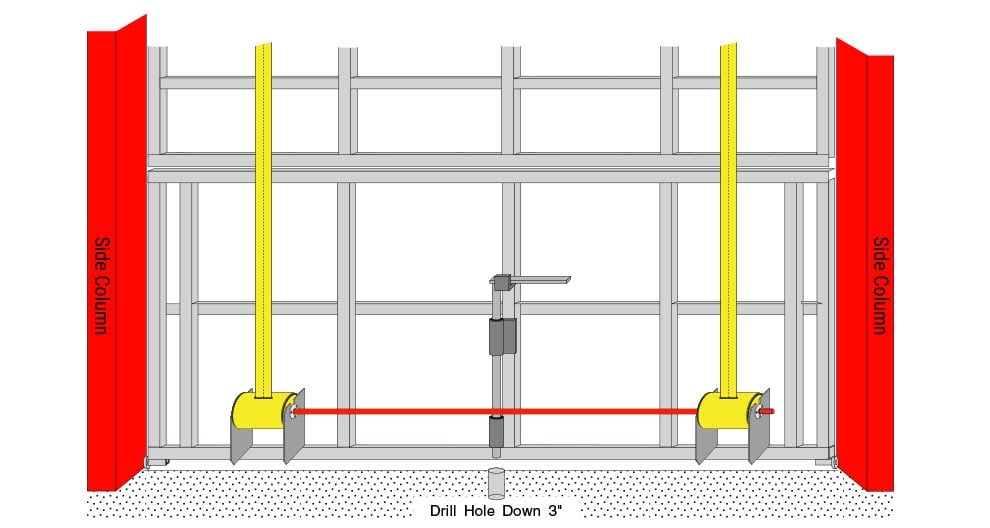

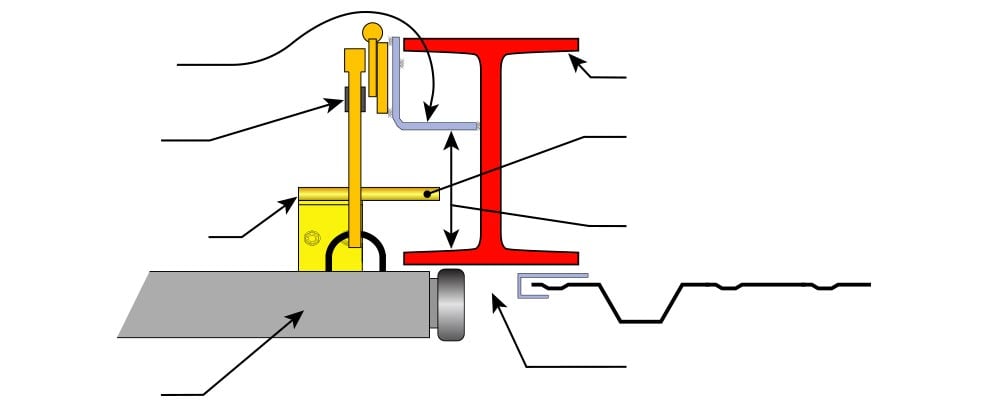

WIND PINS USED FOR EXTRA SUPPORT

Center wind pins - 1" diameter minimum

Furnished on Bifold Doorframes to increase the load strength and provide a sturdy installation.

Bifold Doors