Schweiss will work with you, your architects, contractors, or building supplier to ensure a perfect fit on your building. We supply door weights, engineering data, windload specifications and design specifications to make certain that you have all the necessary information needed for the design of your building to accept the Schweiss door of your choice.

- Schweiss will answer your questions and assist you with your building drawings to make sure your hydraulic door will fit your "New" or "Existing" building.

- Schweiss provides the necessary Detailed A-1 through A-6 spec sheet with each bid / order. These should be read by anyone involved with the selection or purchase of the industrial door of your choice.

- Schweiss will provide you with the specific loads that are applied to your building and door.

- Schweiss provides the actual measurements, movements, weights, and hinge locations.

- Schweiss provides the actual measurements for your door covering / sheeting. If you have any questions about Schweiss doors or need technical assistance, feel free to call us at (800) 746-8273.

Building

Stub

Column

By Bldg

Mfg

Bldg

Column

Building

StubColumn

By Bldg Mfg

Mounting Holes To

Attach To Your Building

Bldg

Column

Attachment

Angle

Door Hinge

Dooframe

Continuous

Header Tube

Door Frame

Cylinder Leg

Supports

Building Mainframe

Building Sheetinge

Stub Columns

Lateal Bracing

The lateral bracing will

support the building

column / cylinder leg

from the forces of the

door.

Total clear opening height

Distance from finished floor to the very top of door framework.

Distance will vary on different size doors.

Distance from finished floor to beginning of building sheeting.

Distance from finished floor to center of the mounting hole.

Schweiss Bifold Doors is proud of our new "One-Piece" custom built hydraulic doors that swing out and require no headroom. Already a leader in the bifold door industry, Schweiss Bifold Doors continues to bring new quality products to our customers with the introduction of the "One-Piece" line of custom built hydraulic swing doors. Our "One-Piece" doors provide a one-piece design that requires zero headroom, comes prehung, is watertight, easy to install, easy to operate, easy to insulate and will swing out to provide a canopy.

Many industrial buildings, manufacturing facilities, and aircraft hangars require wide doors and a high inside clearance. Schweiss Doors are ideal for any type of building that requires a high clearance inside the building. A Schweiss bifold or hydraulic door provides you maximum access to your building's available storage space, allowing you to get full value from your facility. Start utilizing your building to its fullest potential with a high-tech door.

We need to know the clear inside measurements, or

air opening, height and width

We hang our door up and above your clear opening,

on the outside of the building, so we won't lose any

headroom! We usually hang the door 12", 24" 30" or

36" above your clear opening. This will vary from

door to door.

We need a header placed at 12", 22", 28" or 24" to

center above your clear opening to hang our door!

You can build this into the endwall of your new or

existing building.

Shows how a header is installed in an endwall of a

building and where. The header is placed up and

above the bottom of the rafter so you won't lose any headroom!

This drawing shows how the bifold door rolls up

the outside of the building column.

Your door will look like this when fully opened. Lose

no headroom!.

WE AT THE FACTORY WILL HELP FILL IN THE "SPEC SHEET DETAILS".

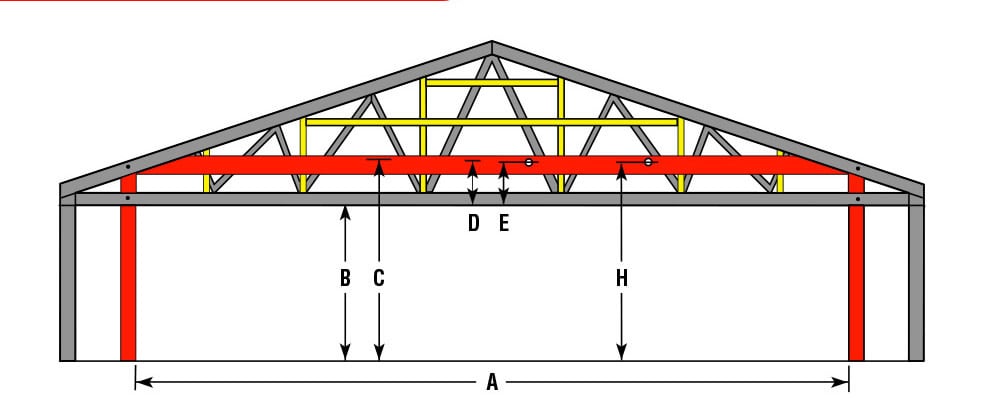

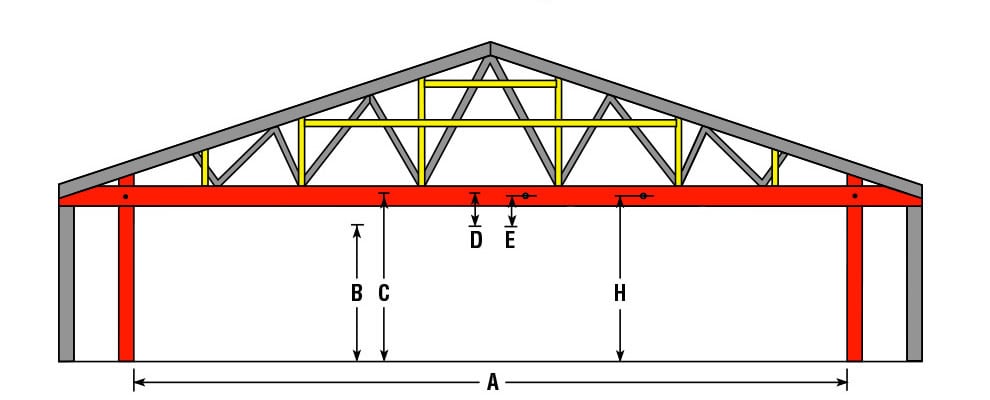

A._____ Clear Opening between building Side Columns - Finished Opening.

B._____ Clear opening from bottom of truss to finished floor - or total clear height opening.

C._____ Distance from finished floor to the very top of door hinge. B+D=C.

D._____ Distance from top of clear height to top of single hinge. This distance will vary on different size doors.

The distance above your clear opening will be 12"-24"-30"-36"-48"-Other _______. Circle One.

E._____ Distance from top of clear height to center of mounting hole for single hinges.

F._____ Distance from finished floor to beginning of top building sheeting.

H._____ The distance from the finished floor to the center of the mounting hole for the hinges.

Very Top

Of Hinge

Bottom of

Building Sheeting

Door Wide Open

Bottom of Header /

Rafter / Ceiling Height

Top

Sheeting______

Bottom

______

Very Top

Of Hinge

Bottom of

Building Sheeting

Door Wide Open

Bottom of Header /

Rafter / Ceiling Height

Side Column

Side Column

Outside

of Building

Doorframe overlaps 1" on each side

Door Sheeting

Doorframe width

The side rails overlap the side columns

AA Area left unsheeted

Customer, Contractor/Owner, Building Manufacturer, Architects, Building Suppliers

The customer, contractor/owner and the building manufacturer are responsible to ensure that the building's structural design is capable of handling all the imposed loads that the bifold door exerts on your door header, endwall, and building. When your bifold door is in a full open position, the bifold door tends to pull away from the building at the hinge line exerting considerable horizontal loads on the building structure in the open position. Your building header design must meet standard deflection and strength criteria, both in vertical and horizontal directions to support the bifold door in all positions.

We will work with your architects, contractors and building suppliers to make sure the door you order will fit your clear opening and building. We will answer your questions and assist you with shop drawings to make sure that your "Automatic Bifold" door will fit your new or existing building. Available are the door weights, loadings, hinge locations, specs and fine details.

Schweiss Bifold Doors will provide you with those loads that are applied to your building and door. We will provide you with our A-1, A-2, A-3, and A-4....A7 Spec sheets for your actual measurements, movements, weights, and hinge locations.

WARNING:

Improperly designed bifold door header can result in property damage, personal injury

or death.

Your building header design must meet standard deflection and strength criteria both in vertical and horizontal directions to support the bifold door in all positions.

Door SpanAllowable Deflection

0' - 50'1"

50' - 70'1.50"

Over 70'2"

THE SCHWEISS HANDBOOK IS DESIGNED TO SHOW:

The many different ways to attach a bifold door to your new or existing building structure (wood, steel, Quonset, sidewalls, etc.) Detailed illustrations to help you further understand how to prepare your building for a bifold door, without changing the design of your steel or wood building. There are many different applications of an optional freestanding header.

The Schweiss Handbook should be read by anyone involved in the design, specifications, selection or purchase of an industrial bifold door operator or automated bifold door system. Any illustrations or numbers shown in this book are for examples only. Upgrade equipment is available from Schweiss Bifold Doors and is strongly recommended that upgrade equipment be used on every bifold door.

WARNING: Without the proper upgrade equipment, the door could cause property damage, personal injury or death.

If you have any questions about bifold doors or need technical assistance, feel free to

call us at (507) 426-8273.

Thank You

Schweiss Doors

Lateral Bracing

Stub Column

Side Column

Bottom

of Stub

Top Of

Header

Overall

Height of

Bifold Door

Clear

Opening

Steel

Side

Column

Sidewall

Girt

Inside of

Building

Outside of

Building

Building

Line

Sheeting is on the same plane

Doorframe width

Doorframe overlaps 1" on each side

Side rails overlap the side columns 3" to 4"

AA - Distance to step back with the sheeting

Steel

Side

Column

Sidewall

Girt

Inside of

Building

Outside of

Building

Building

Line

Sheeting is offset

Doorframe width

Doorframe overlaps 1" on each side

Side rails overlap the side columns 3" to 4"

AA - Distance to step back with the sheeting

Wood Side Column

Inside of

Building

Outside of

Building

Building

Line

Sheeting is on the same plain

Doorframe width

Doorframe overlaps 1" on each side

Side rails overlap the side columns 3" to 4"

AA - Distance to step back with the sheeting

Wood Side Column

Inside of

Building

Outside of

Building

Building

Line

Sheeting is offset

Doorframe width

Doorframe overlaps 1" on each side

Side rails overlap the side columns 3" to 4"

AA - Distance to step back with the sheeting

Clear Opening

Wedge Stub Columns on

Steel Buildings 1' below "C" Measurement

Clear Opening Height

(Provided by Customer)

Clear Opening - Between Columns

12" Wedge

24" Wedge

36" Wedge

12" Clear Opening

12" Clear Opening

12" Clear Opening

Door in Wide Open Position

Door in Wide Open Position

Door in Wide Open Position

Side

Column

Stub Columns

Lateral Bracing

C-channel or purlin to attach

the endwall sheeting to above

the Bifold Door

Endwall

Building

Main Frame

Door rolls up

on face of the

side columns

Overall

height of

Bifold Door

Clear

Opening

Height

Door

Column

Door Column

Header Plate And The

Door Column Must Be

Flush

Stubs Welded Or Bolted To The Mainframe Or The

Continuous Header To Support The Door Header Plate

Dotted Lines Represent The

Header Plate

Endwall Sheeting Above

The Bifold Door

Main Building

Frame

Clear Opening - Between Columns

Distance To Stay Back With The Sheeting

Door

Column

Door Column

Header Plate And The Door Column Must Be Flush

Main Building

Frame

Endwall Sheeting Above The Bifold Door

Stubs welded or bolted to the mainframe or the continuous header

to support the door header plate. The door can also be attached to the

vertical stubs only leaving the continuous header off, just another way

to support the doorframe.

Clear Opening - Between Columns

Distance To Stay Back With The Sheeting

Shows where a header is installed in an endwall of a building. The header is positioned up above the

bottom of the rafter so you won't lose any headroom!

Shows where a header is, using the bottom chord in an endwall of a building.

The engineered rafters can be doubled up for sufficient support

2 x 6 Vertical

Triple Vertical Stiffeners -

Three 2x6's By Each Hinge Location

Tie Back Brace

2 x 6 Vertical

Need A Backer Plate

To Apply The Bldg.

To

Header Bolt

Ceiling

Need A Backer Plate To

Apply The Bldg. Sheeting

To This Area

Double End

Wall Rafter

Ceiling

Built In

Header Plate

3rd

2nd Building Rafter In

From The Endwall

Triple Vertical Stiffeners

(3) 2x6's By Each Hinge

Location

How To Strengthen

Your Endwall Rafter

Bolt Rafter To

Each Side Column

Side Columns Must Be Full Length

(on Larger Doors Double The Side Columns)