Bifold Doors

Why Lift Straps

Hydraulic vs. Bifold

Strap Conversion

Stories

Must See Photos

New All Strap Bifold Door

Why One-Piece Hydraulic Doors

Retrofit

Strap Conversion Kits

Farm Stories &

Photos

New Strap Latches

Hydraulic Hinge

On Steroids

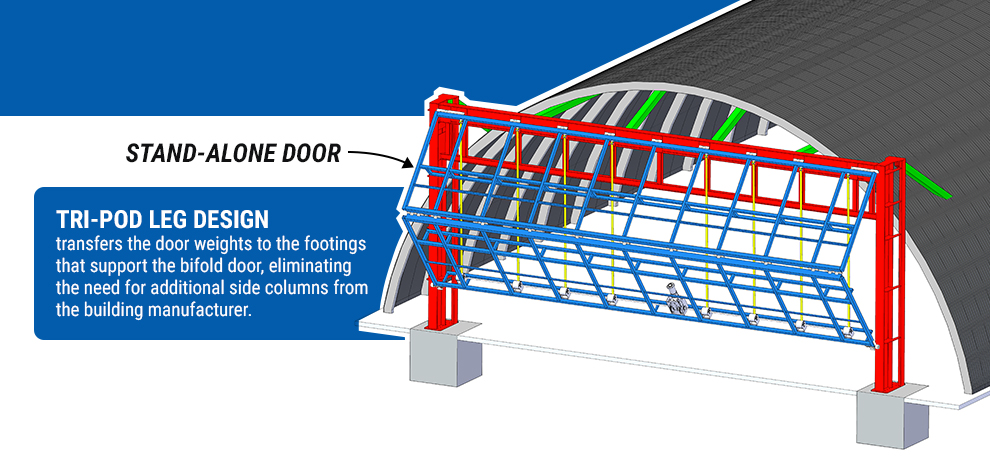

Stand-Alone Doors

Schweiss Designer Doors

Schweiss Doors of Hector, Minnesota, has completely raised the bar in terms of hydraulic and bifold doors for aircraft hangars, and commercial and industrial use.

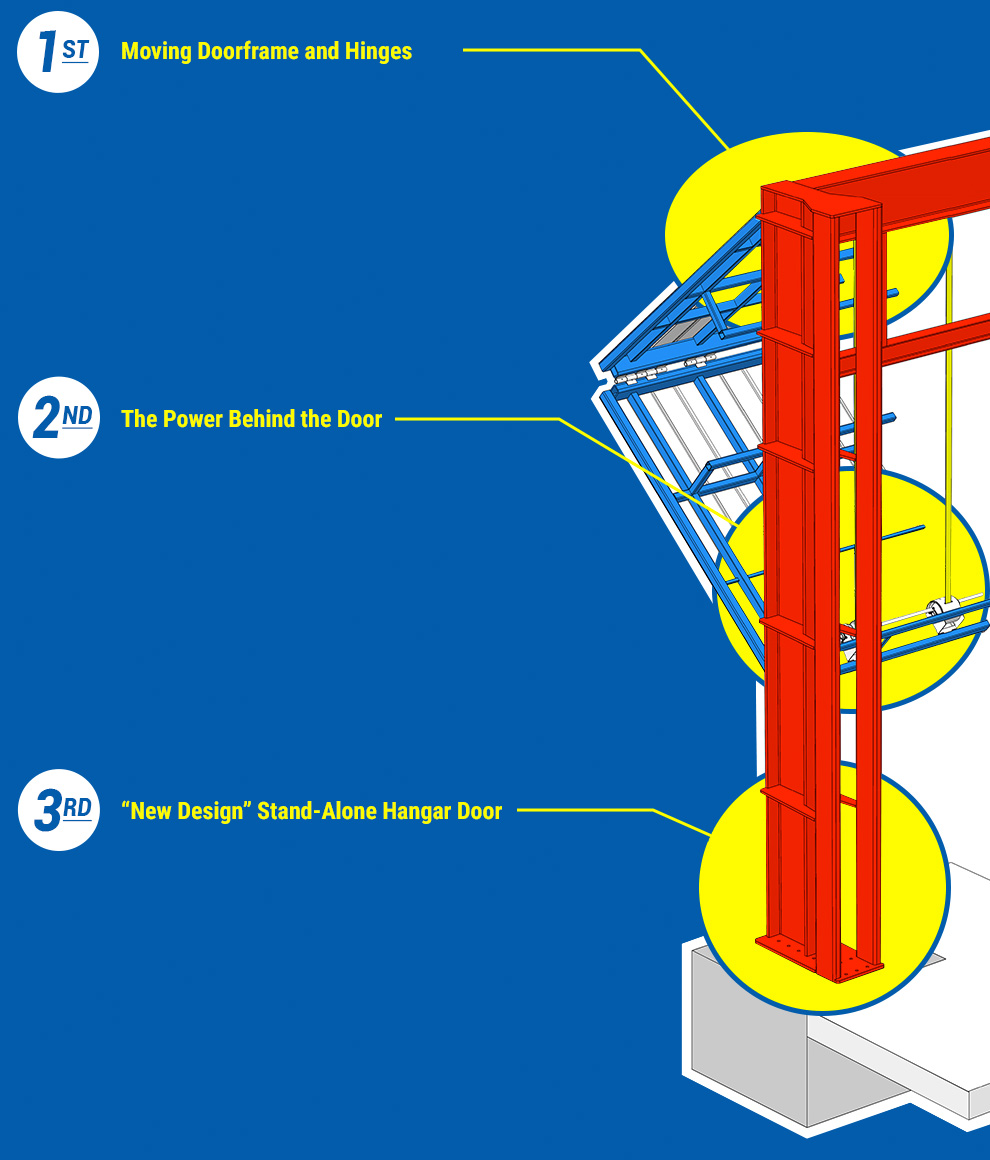

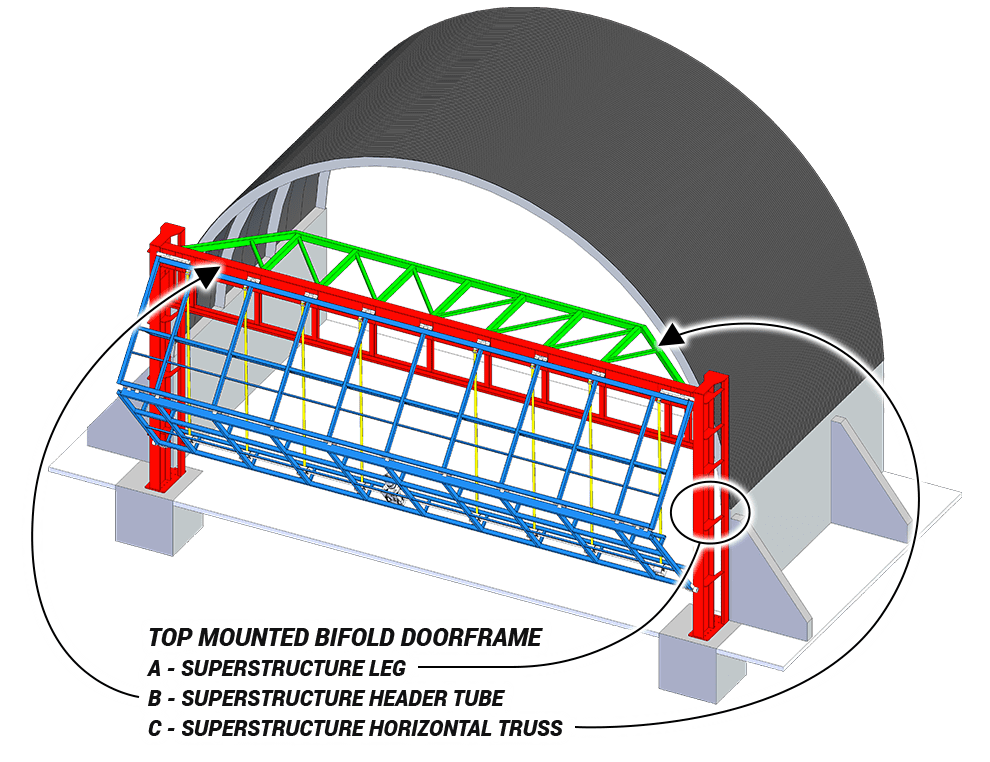

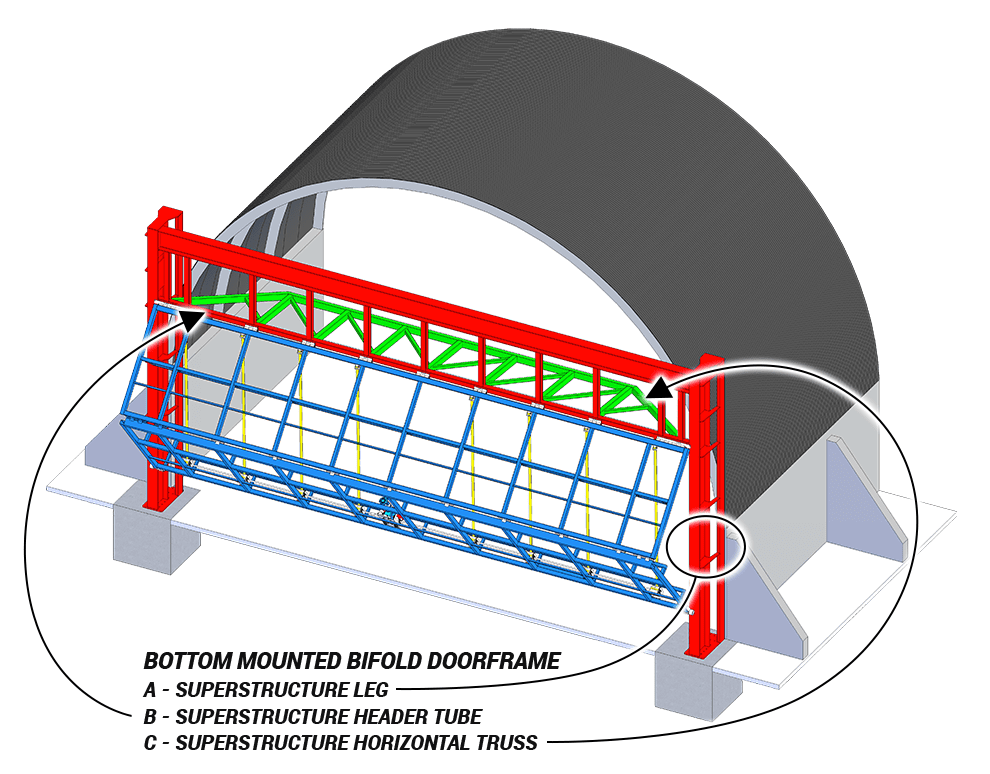

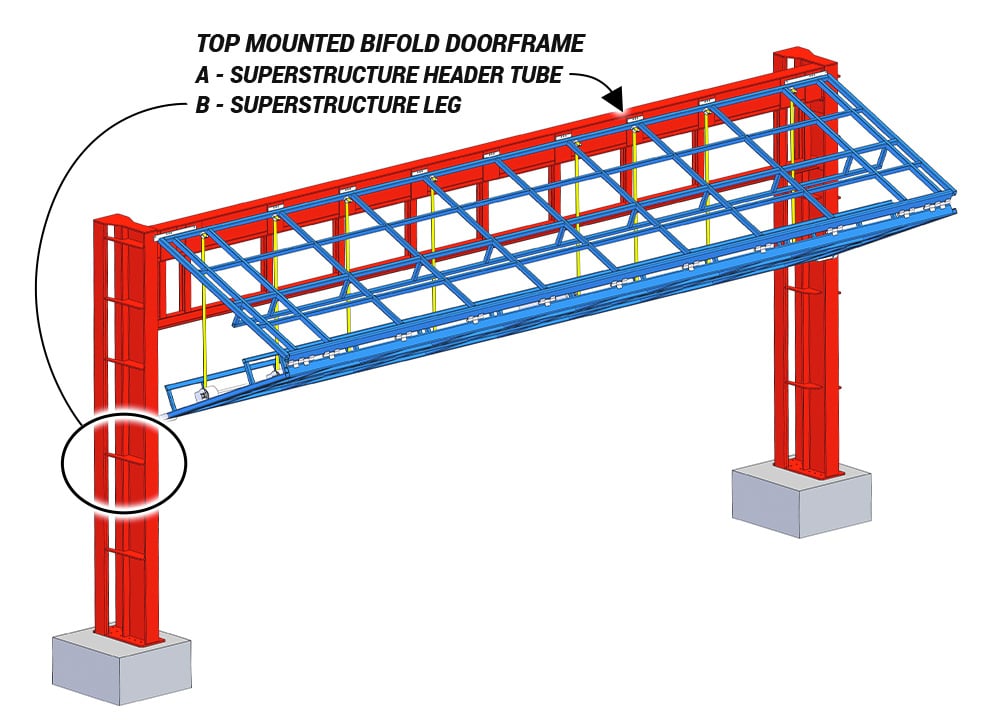

The new “Schweiss Superstructure Triple Leg Stand-Alone Door” is the only one of its kind. This trialblazing tripod leg design transfers the weight of the door to the footings that support it, eliminating the need for additional side columns from the building manufacturer, significantly reducing building costs.

The free-standing door has its own superstructure

framework attached that can be added to the client's new or existing building. It's all self-contained, so a retrofit is easy. This hangar door is so strong, yet so simple, that it requires nothing more than a common framed opening.

The stand-alone design eliminates the need for the building manufacturer to utilize a building truss or header to support the door on the building structure itself.

"When you're designing a door, build a new model that makes

others existing door models on the market obsolete."

"Schweiss has done that!"

Self Supported Bifold Door Design . . . For Your Buildings!

Schweiss has completely raised the bar in terms of hangar doors for general aviation and commercial jet hangars. We apply common sense and an innovative approach to provide you the right hangar door solution for your building. Schweiss realizes it's important to understand what impact the hangar door will have on your building. Schweiss offers all hangar manufacturers choices when designing their buildings.

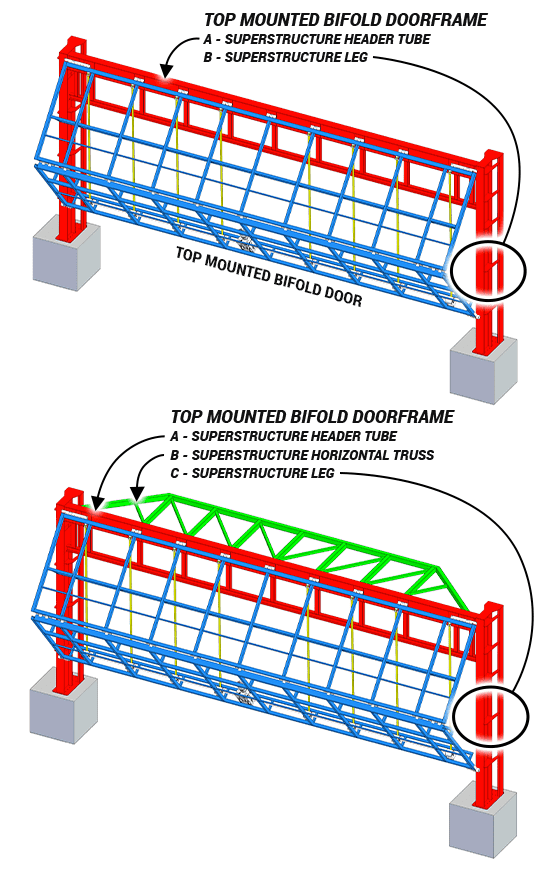

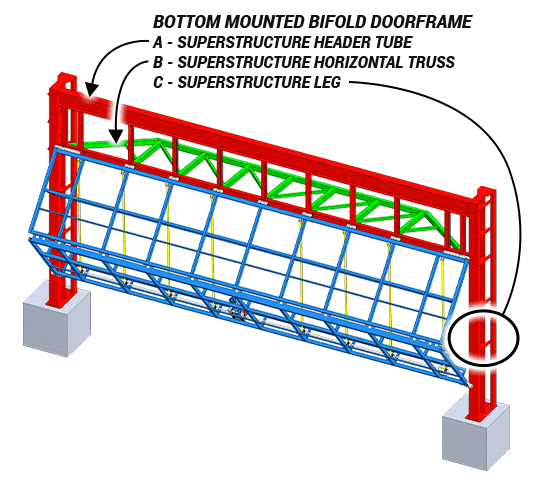

Schweiss has the capability to manufacture a bifold door and framework that's designed to help support the building structure. It is a freestanding bifold door that has its own superstructure framework attached and can be added to your new or existing building structure. It's all self-contained so a retrofit is easy. This hangar door is so strong, but yet simple, that it requires nothing more than a common framed opening.

A Schweiss superstructure doorframe mounts on the 'New Stand-Alone "Self Supported" doorframe; eliminating the need for the building manufacture to utilize a building truss or building header to support the bifold door on the hangar structure itself. This means you can reduce building costs significantly and gain headroom; saving everyone dollars.

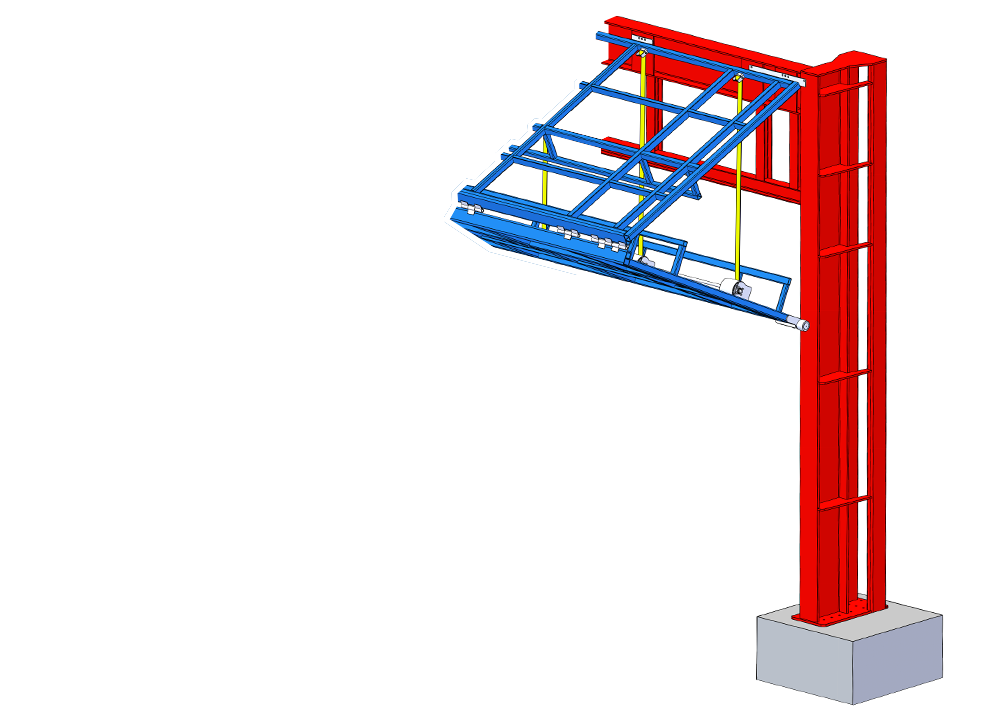

Robust Hinges . . . Give the door stability in all positions!

Schweiss Patented Hinges - Our proprietary robust hinge design connects the moving doorframe to the overhead structural subframe, providing a considerably stronger and greater surface area for distributing the load of the moving door evenly. The hinges and subframe provide the structural strength that carries the weight of a large moving doorframe! Robust hinges have easy-to-grease zerk lubrication and removable hinge pins for extended service life.

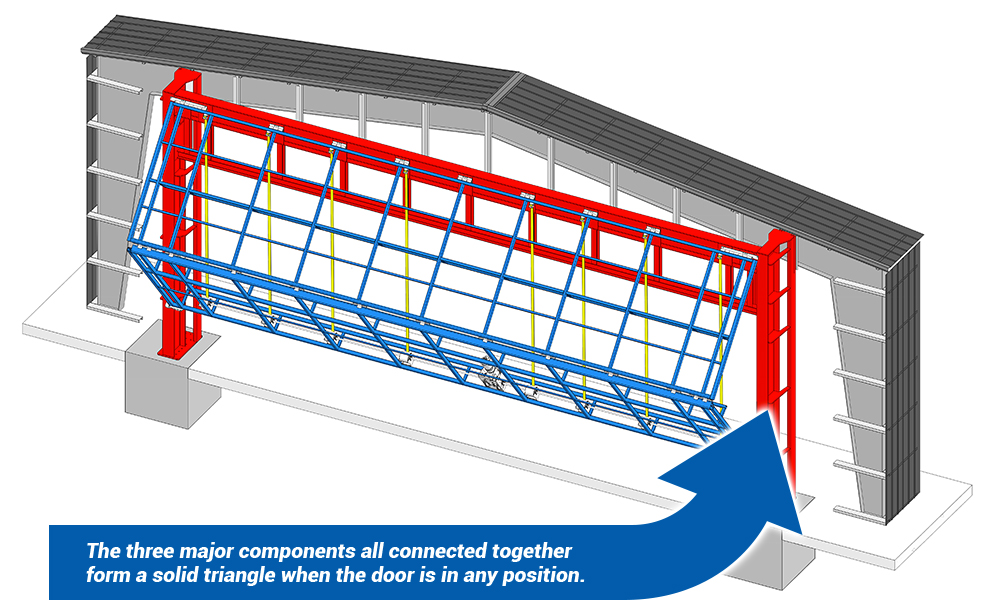

Three . . . Major Components

MAKE THE DOOR BETTER / STRONGER / SAFER

Bifold doors have three major components; the lift-straps, the doorframe and the subframe header.

The three major components are all connected together to form a solid triangle when the door is in any position. By connecting all the major components together it comprises a huge structural advantage and makes the door operation and installation strong and stable.

The three connected components below are what gives our door stability in all positions!

Connect to the overhead structural subframe - that inludes

a robust hinge design providing considerably greater surface area

for distributing the load of the moving door evenly. The patented

hinges include easy access greaseable lubrication zerks and

removable hinge pins for extended service life.

Bifold doors have a huge advantage, by utilizing the major

components for stability! The major components add stability

to the door in all positions and allows for flexibility of the

door and frame without binding on the cylinder pins

and brackets. With all the major components

connected, it makes the door so much stronger

and stable in all positions at all times.

Support the door in all positions. Lift straps

attach to the doorframe across the length of

the door keeping the door stable throughout the

doors travel when opening or closing and also allow

for flexibility.

Lift-straps are connected to the doorframe and are supported

by heavy-duty hinges that connect the doorframe to the subframe

header to better support the moving doorframe in all positions.

By connecting all the major components together it creates a huge

structural advantage. A solid triangular connection gives a moving

door support and accommodates horizontal movement or deflection

to the moving doorframe in all positions, making the door operation and

installation strong and stable.

Attach to the Subframe Header providing the structural strength

that carries the weight of a large moving doorframe! The Tri-pod

structure supports the door and eliminates column twist, distributing

the door weight and loads evenly into the concrete footer - the door

loads are transfered to the floor during operation, not the building.

Tri-Pod Legs - We at Schweiss Doors are the only manufacturer of

the Triple-Leg Stand-Alone Hangar Door. This innovative bifold

door is the only one of its kind. We have taken our existing proven

bifold door and now have even made it better! Schweiss is

known for perfecting and developing better designed doors, and

we have outdone ourselves again!

Lower Building Costs

with Schweiss Superstructure

Schweiss Doors is on the leading edge of bifold doors today

Building costs are significantly reduced with our Tri-pod leg design self-supported bifold

doorframe. Schweiss is the leader in manufacturing hangar doors for general aviation and commercial jet hangars. Our self-supported bifold door is designed with a purpose and a clear objective. The self-supported design will benefit everybody from architects, engineers to building manufacturers, and more importanly will save money for the end-users of the doors.

"To change something, build a new model that

makes the other models obsolete."

While other doors may appear to be the same on the surface, there really is no comparison!

Each door comes prehung with its own frame

• Heavy-duty hinges are pre-welded to the doorframe and horizontal continuous member for ease of

installation.

• They are pre-assembled, pre-welded and delivered pre-hung within a pre-squared frame for ease of

installation. Each door is fully assembled from the factory, saving you hours of installation time.

Compare this to tilt-up doors that are shipped out in a kit form that consists of many bolts, steel

members, cables and other components that have to be field-assembled and be field-squared up at

the job sight. Assembling a kit door takes more time to install!

• Makes installation easy; framework is standard on all Schweiss bifold doors - just lift the

framework and door into place all in one step.

No welding necessary

Schweiss door framework consists of a continuous header that's factory fitted to the tri-pod legs.

The doorframe is attached to the complete framework at the factory making installation easy.

The framework adds extra building support. Schweiss self-contained framework simplifies installation.

automatic strap Latches available

Optional strap auto-latches secure the door in place in the closed position ... never creeps open. The strap auto-latches pull the door in at the hinge line and keep it pulled in tight against your building and will keep the door in a locked position that provides a tight seal.

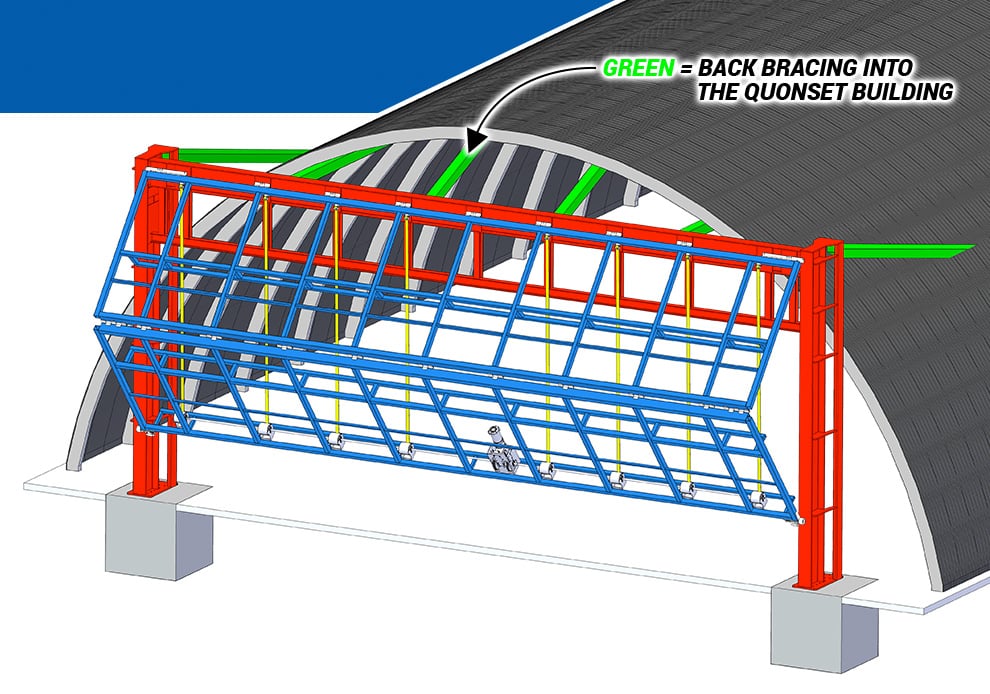

Support Bracing

for Free Standing Header

Self Supported

BIFOLD Door Design

• Schweiss offers choices unlike others, we use

common sense and an innovative approach

to provide the right hangar door solution

for your building. The complete hangar

door system will save you time and money!

• Reduce building costs significantly. Schweiss Doors

come with their own door columns. Schweiss realizes

and understands the impact your bifold door will have

on your building.

• Schweiss doorframes mount on the ‘New Stand-alone

"Self Supported" doorframe, eliminating the need for the

building manufacturer to incorporate a building truss or

building header to support the bifold door on the

structure itself; saving everyone substantial dollars.

• Lose No Headroom . . . Keeps the overall building height

down, since there is no lost height at the opening; unlike

others where the doorframe rolls back into the building.

Schweiss bifold doors put zero stress on the framed

opening. Smartly engineered!

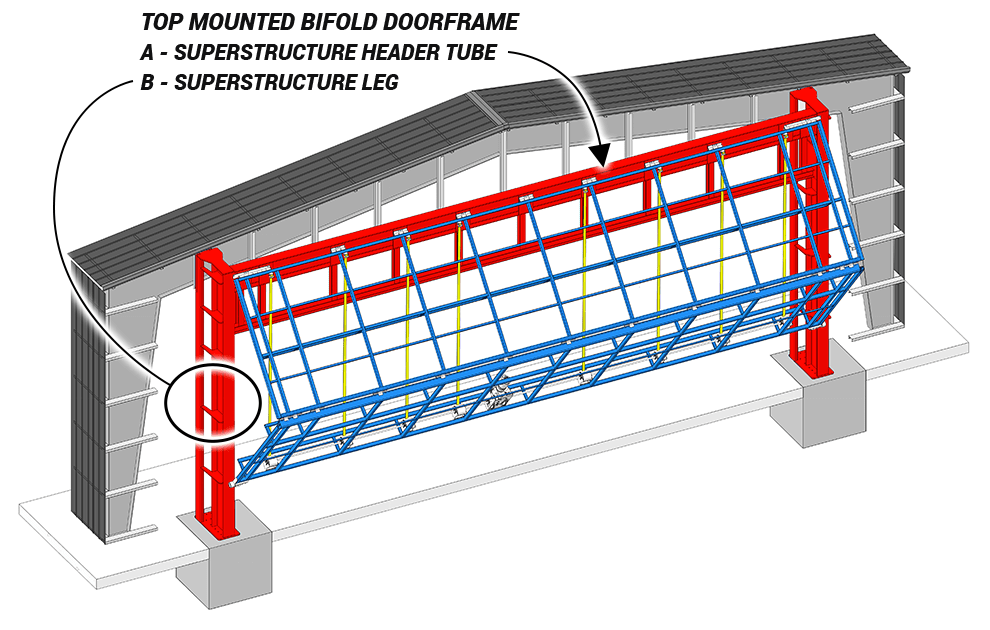

Tri-Pod Leg Design

For Bifold Doors

TRI-POD DOOR HAS ITS OWN SELF-SUPPORTING SUBFRAME

Schweiss hinges distribute the door loads evenly across the self-supporting

subframe greatly reducing stress on the building structure.

• Self supported hangar door is simple yet seamless in design.

• Door does not put additional stresses on the building just to hold the door up.

• Only a "Simple framed opening" is needed, helping save the end-user money.

Building Companies Concerns . . .

They are asking, "Can you manufacture a door

that doesn't hang off of the building header?"

• Building prices began to escalate when

additional engineering is needed on the

buildings structure to handle the loads

of the doors, headers and door supports!

• You can reduce hangar construction costs

and limit headroom requirements

• Helps with sustainability and design

efficiency when designing a hangar

building.

• Helps eliminate major structural issues

when designing the building for a door.

• As the metal building provider, when

would we supply an extra steel header

and horizontal supports. They will add

considerable cost of which not all

customers are not willing to pay for?

• The more structural steel that can be

eliminated from metal building cost

helps everyone dollarwise!

What Building Companies are Wanting...

Schweiss Delivers

Simple Strong Design . . . Schweiss Strong!

• Provides a "rain canopy" when open.

• Provides a "shade canopy" when open.

• Power up and power down fully automatic

with remote control . . . No short cuts!

• Once Schweiss doors are hung, there's

nothing to go out of adjustment.

• Door swings outward, it doesn't impinge on

the hangar or shop interior like tilt-up doors.

• Schweiss doors have less moving parts,

no rollers to keep from falling out of track,

cams or slides.

• Simple, solid design.

• Less Maintenance!

Installation Made Easy . . . With a Schweiss Door

A customer once shared with us ... "A door is a door ... Right? WRONG! Like many people,

I thought all bifold doors were pretty much the same, but boy did I learn my lesson. A bifold door

is only as good as its components. Hinges, straps and workmanship, that's what sold me on the new

Schweiss bifold doors. After helping a neighbor install and operate his Schweiss bifold door, I was sold right there, and from then on I knew Schweiss Doors were the right choice for me! The bifold door secret was no longer a secret. I proudly told my neighbors how happy I was with my Schweiss bifold door."

Schweiss Doorframes are Pre-assembled, Pre-welded

A special feature of a custom-built Schweiss bifold door is that it comes pre-assembled, pre-welded and delivered pre-hung within its frame for easy installation. Schweiss welded doorframes have no bolts to jiggle loose and doors come welded up square from the factory and ready to install! A fully welded doorframe is stronger when all components are pre-welded in place! Welded doorframes are easier and faster to install - no adjustments are necessary once the door is in place. This is a real timesaver for the erector that installs the door. The Schweiss bifold doors can be installed on any building, and best of all they still maintain the headroom requirements ... this is where you can save thousands of dollars by lowering the height of your building and still maintain needed headroom.

• Schweiss doorframe comes pre-assembled with its own header tube and vertical side columns

that provide added support for your building structure.

• The doorframe is pre-welded and pre-hung within the subframe for easy installation.

• Pre-located lift-straps and hinges make door installation easy.

• The doorframe provides additional strength to your buildings.

• All that's needed is to lift the framework and door all into place in one step.

The buyer/builder gains tremendous flexibility, saving time and money

on installation. Let your next hangar door be a Schweiss door!

For Big Doors . . . Buy Schweiss

Schweiss Door Advantages

• Once hung, nothing will go out of adjustment.

• Nothing protrudes back into the building.

• No rollers to pop out of the tracks.

• It's a significant "rain/shade canopy" when open.

• Door is powered up and powered down.