Customers Welcome Greasable Hinges

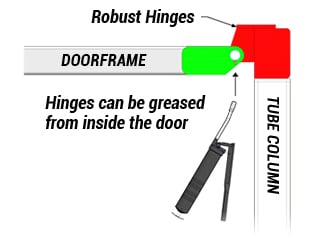

The new hinge design with grease points on every hinge segment enables owners - whether they be private individuals or commercial customers - to periodically grease their hinges from inside the doorframe without having to go through the cumbersome process of first removing the top rubber weather seal.

HINGE SURFACE AREA

Hinge surface area is critical on large moving doors. Over the years, we all have heard of hinge failures on others doors. Large hydraulic cylinders are putting extreme forces on each of the outer hinges of the doorframe. Schweiss has designed and patented a robust hinge with more surface area to evenly distribute the loads of a moving one-piece doorframe. Look at the hinge surface area. The stresses on the very outer hinges are immense. With that being said, take one look at the patented Schweiss hinges and you'll clearly see the workmanship, strength and functionality of each hinge.

GREASABLE HINGES

It's very important to be able to grease the door hinges with a heavy viscosity grease. When grease is used on the hinges of a large moving door it avoids unnecessary wear and adds longer life to the hinge and the doors operation. It's a common manufacturing practice to use grease on the critical wear points and load points to avoid unnecessary wear just like in the industrial equipment world with implements such as payloaders, skidloaders and other industrial equipment that are being operated around the clock.

Advantages of Grease

Using grease on the hinges is a better method of lubrication.

Using grease on the hinges is the industry standard.

Using grease on the hinges makes for a quiet door.

Using grease on the hinges makes for a smoother operating door.

Using grease on the hinges extends hinge life

Greasable hinges last forever.

Look at the Schweiss hinge, it has more lubricated surface area to give you longer life

Others rely on bushing FOR LUBRICATION

Doors move and flex as they open and close. The forces on each hinge vary during operation.