Hydraulic door electrical systems are built for safety - 25

Everything to operate your hydraulic door is at your fingertips with the new Schweiss hydraulic compact pump. The compact pump system can be mounted anywhere within your building. The unique design of the powerful LEESON motor system is designed with safe UL listed components.

Schweiss offers a 220 volt single phase or 3-phase operation, it’s your choice. Door operators are pre-wired and factory tested, complete with a 24 V.A.C. control system.

In case of a electrical power outage at your location, the pump unit has three backup systems available to keep your door operational. They include a standard hydraulic tractor coupler fitting backup or you may order a battery power or drill driven backup.

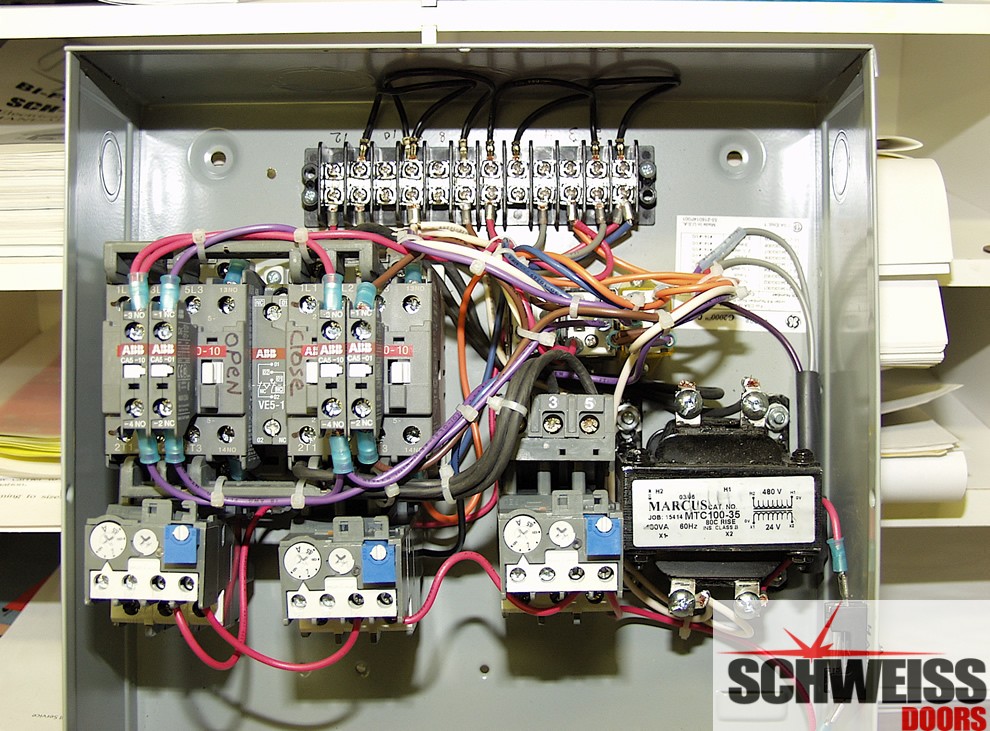

Schweiss hydraulic door electrical control boxes are designed with ample space to safely house all required electric components, such as contactors, transformers, relays, motor timers, rectifiers and control fuses.